Philco 20B Cathedral Restoration

|

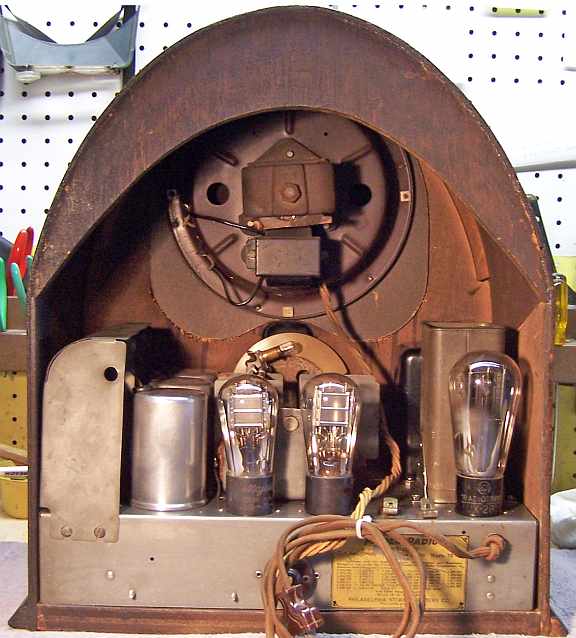

The Philco 20B is a large 7-tube rounded top TRF circuit radio dating

from around 1931. It only receives the broadcast (medium wave) band. My

example is the later version of the Model 20. The radio had seen

minimal servicing in the past and most original

parts were still in place. This being the case, I

decided to try to retain the original top and bottom chassis appearance if

possible, yet get it working and replace all capacitors, check resistors

and tubes, etc. for long term reliability.

A schematic and parts list, as well as a parts placement diagram can be

found online at Nostalgia

Air. A more useful schematic, with annotated parts values, can be

found at Philcoradio.com

(late version).

|

My

antique radio restoration logs

Condition As Found

The radio was purchased at the 2014 CC-AWA Conference and Flea

Market, in Charlotte, in the old equipment auction. The radio is the

"Deluxe" version of the Philco Model 20 which has decorative curly

maple trim around the grille area. There was no external sign of any servicing

or restoration having being

done. The cabinet finish, grille cloth, power cord, and knobs appeared original. I always avoid

purchasing a radio that has been "restored" by a collector or flipper,

since they may take shortcuts such as discarding the original capacitors. I

prefer to "restuff" the original parts in order to preserve the

original chassis appearance. To me, radio restoration is a hobby - not a

business - so time is not a factor. I did not attempt to power up the radio

prior to servicing. It was likely working as found! The model 20 uses paper type

filter capacitors rather than electrolytics, which would have dried up or

possibly failed after 80 years.

Previous Servicing

When

I nervously pulled the chassis for inspection. I was pleasantly surprised. There

was no sign of any restoration or servicing having been done (other than tube

replacement). All the original parts looked to be in place. Even the cloth

covered power cord was original, and in good condition. The power plug

looked like an older replacement.

-

All filter, paper, and bakelite block capacitors

were original. However, once I began removing the Philco bakelite block

capacitors for restuffing, it was discovered that one of them (part 19 - the

audio coupling capacitor) already had been restuffed using a new 630 volt

film capacitor. The part had then even been resealed with some sort of wax

(likely beeswax). I doubt that a service shop would have gone to the

trouble.

-

All resistors were original.

-

Three engraved base globe type 24 tubes were installed.

Their original Philco paper labels were still in place, and their date codes

1H (1931?) indicated that they were likely original. The type 71A audio tubes were globe types, but

were not original. They were branded Majestic. The

27 and 80 tubes were also replacement. They were not globe types, and were

not branded Philco.

Cleaning

The first step was to blow off the dust using an air compressor.

After removal of the tube shield, tuning capacitor and filter capacitor, the chassis and remaining top components were cleaned using GoJo,

00 steel wool, and various small brushes.

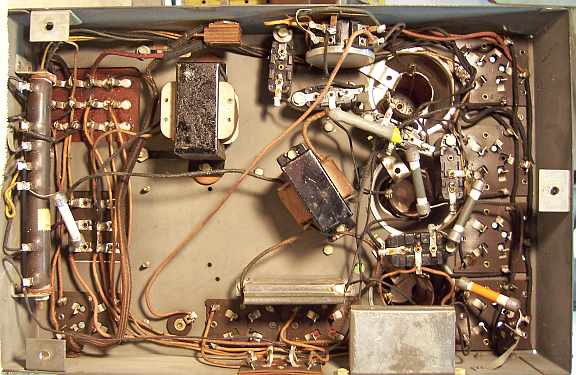

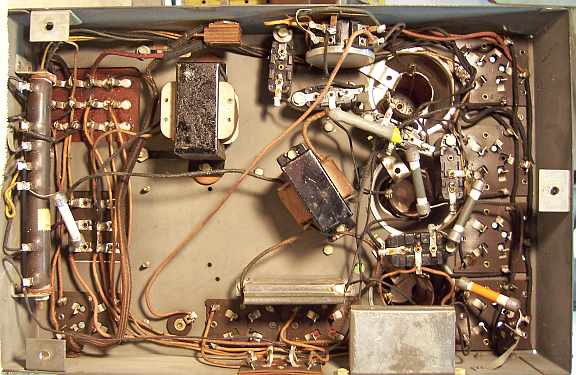

Survey

My usual restoration procedure is to take photos of the original

chassis top and bottom for future reference. I then make a complete

survey of the condition of all components and repair all items before the radio

is tested. I assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original components if possible). I

do not replace mica capacitors, but may test them in place if possible.

-

The power transformer was OK. The high voltage was balanced

on each side of the center tap with 10 volts applied to the primary through

a variac. It drew less than 10

watts at full line voltage (unloaded), and all filament voltages were correct.

I always make this test prior to restoration, since some transformers may

have shorted turns which may result in overheating after usage.

-

The speaker field coil, cone, and voice coil were OK.

-

All RF coils were OK (all were tested for resistance and/or

continuity).

-

The audio driver transformer, output transformer and filter

choke were OK.

-

The original cloth covered power cord was OK.

-

The original speaker cable was OK. There was some damage near the

plug. This was likely due to the radio being shoved against a wall (the

speaker plug projects past the cabinet when plugged in).

-

All resistors were old style dogbone types. Some were

cast metal-end dogbones. Four were more than 20% out of tolerance.

-

The type 80 tube showed a short (it was not original). The

three original Philco engraved base globe type 24 tubes were good! All

remaining tubes were also good.

-

The large wire wound resistor was fortunately good. It

would have been very difficult to replace this resistor without grossly

changing the under chassis appearance.

-

Both sections of the volume control measured the correct

resistances. But the wiper for one of the sections did not show continuity

with the resistance element on one extreme end of rotation. This is likely

due to dirt or hardened grease. I decided to wait until the radio was

restored to see what, if any effect this would have. I did not want to

disassemble the control unless I had to. There is really no suitable

new replacement part available, and circuit changes have been published to

allow the use of a standard part.

Restoration Strategy

Since almost all of the original parts were still in place, and

since this was going to be a "keeper", I decided to try to retain the

original top and bottom chassis appearance to the extent possible. All

original capacitors would be rebuilt in their original containers (restuffed),

including the distinctive Philco bakelite block capacitors, the original

filter capacitor, and the metal cased bypass capacitors 13 and 14. Any out of tolerance

resistors would be replaced with the same types if available (otherwise

reproductions).

Repairs

Resistors

The radio uses

"dogbone" type resistors. Most of of them were the older

"cast end" type with solid metal ends. One was the later

"wound end" types with the radial component leads wound around the resistance

element and then soldered together. Four were hopelessly out of tolerance

and would have to be replaced (parts 12, 15, 17, 20).

In most cases,

I would replace an original resistor only if it was not within +/- 20% (or

marked tolerance). One resistor (part 18) measured about 26% high, but it

was not in a critical position and was left in place. I normally replace any "dogbone"

resistors with the same type resistor if available.

I keep a stock of NOS and used "dogbone" resistors, and buy all I can

on eBay and radio swap meets! Of course, most of these resistors, even NOS resistors,

would have also

drifted in value and no longer have their marked values. My solution is to

find a replacement resistor of the correct value and size as measured (ignoring the

markings), and then repaint it to the needed value codes using enamel hobby

paint! Lead length is also considered, as some replacement resistors

need long leads.

I was able to find suitable resistors in my

stock of "dogbone" resistors for most replacements. But in a couple of

cases I was forced to use wound end dogbones for replacements rather than the original

cast end types. I have observed other Philco radios of this age that use a

mix of types. The color coding scheme used in this radio was unfamiliar to

me. The normal color coding scheme used for dogbone type resistors is

body-end-dot (1st digit, 2nd digit, multiplier). But in this case another scheme

was used. In one case, there was a single wide orange stripe in the center of the

resistor (part 12, 50K). Solid gray was 500K (parts 17 and 20). Solid gray with

a yellow end was 100K (part18), and plain white ceramic (no paint) was 250K (part 15). The

original paint on the replacement resistors was removed using lacquer thinner,

leaving a plain white ceramic body for the cast end types. Here are the

replacement resistors:

Capacitors

All the capacitors used in the Philco model 20 are paper type

capacitors - no electrolytics are used. All capacitors were rebuilt in their

original cases using new film capacitors. Three types of capacitors are

used: the normal Philco bakelite block capacitors, metal cased bypass capacitor

blocks, and the filter capacitor block.

Metal Cased Bypass Capacitors

These capacitors are very easy to rebuild. Metal tabs retain a

fiber cover. The common ground connection is soldered to the metal case.

Once this connection is unsoldered, the contents can be easily removed by

straightening the retaining tabs, removing the fiber cover, and then removing

the old capacitor which is wrapped in a fish paper insulator. I keep

the fish paper insulator and re-use it. The original leads were unsoldered

from the old capacitor and were re-used also. Because of space limitations

(width) some new 630 volt film capacitors were too large (I normally only stock

630 volt axial film capacitors). For part 13 (0.5mfd) I used a 0.47mfd/400 volt

radial film capacitor I had in stock. For part 14 (two 0.25mfd units) I used two

0.1mfd/630 volt axial film capacitors for one unit and my remaining 0.47mfd/400

volt radial film capacitor for the other. New radial film capacitors are

much smaller than the axial units.

Filter Capacitor Block

The filter capacitor originally contained four paper capacitors:

two 1mfd, one 1.5mfd, and a 0.13mfd. I used two 1mfd/630 volt, a

0.15mfd/630 volt, and a 2.25mfd/630 volt for replacements. There is plenty of

room inside the case once the original contents are removed. The new parts can

be installed on the back side of the terminal strip. The problem is getting the

original parts removed - they are buried in tar! If smaller radial film

capacitors are used, it is likely possible to mount these on the terminal board

without having to remove all of the tar and contents. On a previous model 20

restoration I used heat - which was very messy! The cover with its terminals

were first removed. The leads from the terminals to the capacitor were

then cut. The capacitor was then placed one an old baking tray covered with foil

in an oven at 275 degrees for about one hour facing downward (propped up using

wooden supports). Most of the tar ran out. I then had to dig out the capacitors

and clean up the tar! This time I decided to try using mechanical methods

without heat. As much tar as possible was first removed using a variety of

tools. Once the capacitor foil packs were exposed, I was able to dig them

out. Once one thin one was removed, that left space to manipulate the

other ones. A heat gun applied to the case softened the tar permitting

removal of the capacitor packs - one at a time.

|

|

Rebuilt Filter Capacitor |

Bakelite Block Capacitors

All original Philco bakelite block capacitors were removed from the radio,

one at a time, making careful notes of connections, their contents

removed, cases cleaned using lacquer thinner, and restuffed using modern 630

volt film capacitors. Before removing the contents I unsolder the internal

capacitor leads from the outside terminals and clean off the terminals. I use

mechanical methods of removing the bulk of the potting tar and capacitors (small

screwdrivers). One must be careful NOT to pry against the bakelite case,

as it is easily broken. Some collectors use heat to remove the contents.

Here is an example of a restuffed bakelite block capacitor from another

Philco restoration:

Other Repairs

The type 27 first audio amplifier tube was replaced with a type 227 globe

type. The defective 80 rectifier was replaced by a type 280 globe

type. Both were RCA engraved base types. The originals or course

would have been Philco branded. All original tubes would have been globe type in

1931.

Cabinet

The cabinet was in excellent shape. It was cleaned with GoJo hand cleaner

and 00 steel wool. There was almost no dirt or any oxidized finish

removed. I suspect that the cabinet previously had been cleaned and

possibly sprayed with some sort of finish, possibly lacquer. The original

patina, grain filler, and stain remained - the cabinet had not been stripped or

refinished.

Testing

After the radio was completely reassembled, power was applied through a

wattmeter and fused Variac. Power was brought up slowly while monitoring

the B+ voltage and the wattmeter. The radio came alive

immediately. The radio was then aligned. Alignment is

straightforward with only three adjustments. I did make the mistake of

aligning the set out of the cabinet. When tested in the cabinet, the dial

pointer (on the escutcheon plate) did not line up with the frequency on the dial

scale. So I had to redo the alignment with the radio in the cabinet.

Restoration Results

Most of my restoration objectives were met, but not all. There was no

intention of restoring the set to factory new appearance! My objective is

usually to reverse any prior servicing and make the radio appear to have never

been repaired. I do not go so far as to artificially "age"

solder joints, as do some collectors! Nothing gives away a restoration

faster than bright and shiny solder joints. Here are some of my

"misses":

- Two replacement dogbone resistors were not the same type as the

originals.

- The existing power plug was re-used. I have no idea what type would

have been used originally.

- Only three tubes were branded Philco (and were likely original).

Chassis Before Restoration

After Restoration Photos