Philco Model 38-9 Restoration

|

The Philco Model 38-9 from 1938 is a 6-tube AC Superhet

circuit radio that

receives the broadcast band and one short wave band. The radio had been serviced in the past but most

of the original

parts were still in place. I

decided to try and reverse all prior servicing and restore the original chassis appearance if

possible. The schematic can be found on-line on Nostalgia

Air. Any part number references in the text below reference that

schematic.

|

My

antique radio restoration logs

Overview

The radio was purchased on eBay and was said to power up and

hum, but no reception (very likely the seller did not connect an antenna!). The radio appeared complete and in good condition.

The radio is a 6-tube superhet that receives the broadcast band and one short

wave band. Although it has 6 tubes, the circuit uses two tubes for the second

detector/AVC and first audio amplifier, when both functions could have been

performed by a single 6Q7G tube - tube count inflation! Features include a

two-speed tuning control and three-position tone control combined with the

on-off switch.

Previous Servicing

I always attempt to avoid purchasing radios that have been

"restored" by collectors or flippers, and am looking for either all

original examples or those which have been "lightly serviced" in the

distant past by radio service shops, rather than peppered with new film

capacitors. This radio had received some prior

servicing, but had not been badly hacked or restored. Most of the original

parts were still in place, including both filter capacitors..

- The 5Y4G tube was branded Philco and may have been original. The 6K7G and

6F6G were branded Sylvania and may have been original. All the rest of the

tubes were replacements.

- In 1938, Philco, like Zenith used only G type tubes with shields where

needed. Metal tubes or GT types cannot be used, since the shield base

internal diameters are too small to accept these tubes. Unfortunately, many

service shops at the time did not stock G type tubes, preferring more modern

metal or GT types. It was very common to find the shield bases bent and

damaged so that these tube types could be used. In this radio, the 6J5G and

6K5G bases had been damaged and GT type tubes used. The 6K7G shield

base was OK, and a G type tube installed (likely original - branded

Sylvania).

- The AC line cord was likely original, but was rotted and spliced to a

length of twisted cloth covered wire. A large clamp type heavy duty plug was

installed.

- A phono input jack had been added, connected using a length of shielded

wire (fortunately, no holes were drilled into the cabinet or chassis!)

- The wire leads to filter capacitor 11 and 11A had been cut and two tubular

electrolytics tacked in under the chassis. Filter capacitor 45 was still in

place and leaking. No replacement had been installed for this

capacitor!

- Three wax-paper capacitors had been replaced: parts 24, 28, and 38. A

0.1mfd capacitor had been added which connected the 6K5G audio amplifier

grid directly to the cold end of the second IF transformer, thus bypassing

the volume control! I have no idea why this was done, unless it

somehow related to the added photo jack. All remaining wax-paper capacitors and all resistors were original.

- Several capacitors and one resistor had been moved and their location no

longer agreed with the Philco parts placement diagram. In one case, the

resistor 36 looked original and this may have been a production change. I

left this resistor in the as-found location (it had to be replaced, since it

was out of tolerance).

Cleaning

The chassis was dusty, very dirty and had a few rusty areas. All tubes

and shields were removed. The dust was vacuumed

and blown off, top and bottom using an air compressor. After removal of

filter capacitors 11/11A and 45 (for restuffing) and the tuning capacitor and

dial assembly, the top of the chassis was cleaned using GoJo (white) hand

cleaner and 00 steel wool.

Survey

-

The speaker cone, field coil, and output transformer were

OK.

-

All coils and the IF transformers were OK.

-

The power switch (combined with the tone control switch) was

bad. Likely the contacts had oxidized or were dirty. A shot of GC Big

Bath spray followed by repeated operation of the switch cleared up the

problem.

-

The tuner reduction drive was not operational (likely due to

hardened grease).

-

The tuner anti-backlash mechanism springs were not in

position which caused the tuner to jam at some point in rotation.

-

The power transformer was OK. The high voltage winding was balanced

on each side of the center tap with 10 volts applied to the primary through

a variac. It drew less than 10 watts at full line voltage (unloaded), and

all filament voltages were correct. I always make this test prior to

restoration, since some transformers may have shorted turns which may result

in overheating with usage.

-

One section of the wire wound resistor 43 (Candohm type)

measured 37% high and the resistance was unstable (it changed when the lugs

were

moved). The remaining two sections were OK.

-

Tubes: the replacement 6A8 (metal) was bad. The likely

original 6K7G and 5Y4G were good. The likely original Sylvania 6F6G was very

weak. The replacement 6K5GT was shorted, and the replacement 6J5GT was very

weak. The 6A8, 6J5, and 6K5 should be G type tubes.

-

The shield bases for the 6J5G and 6K5G had been severely

damaged in order to install GT type tubes.

-

The speaker cable was frayed and bare near where it enters

the chassis.

-

The 6K7G grid cap lead was frayed where it entered the top

of the IF transformer.

-

Five resistors were out of tolerance (more than 20%).

One (part 12) was a 3-watt dogbone type. The remainder were carbon

composition types.

-

The dial lamp was OK.

-

The line cord was rotted and unsafe. The original plug was

long gone, and a length of heavy twisted cloth covered heater wire spliced

onto the existing cord, terminated by a large appliance plug.

-

A phono jack had been connected between the second detector

grid and ground using a short length of shielded wire.

-

The tuning capacitor rubber mounts were shot, permitting the

tuner and dial to move around excessively. Fortunately reproductions

of these complex parts is available from Renovated

Radios.

-

Several of the rubber chassis corner supports were also shot, which meant that

the control shafts were not properly centered in the cabinet. Again,

reproductions of these parts are available from Renovated

Radios.

Restoration Strategy

I assume that all paper and electrolytic capacitors are leaky and thus should be

replaced. I

do not replace mica capacitors, but may test them in place if possible (usually

this requires disconnecting one lead of the capacitor). When I replace a component, I

always remove the original part and any wire fragments completely from a terminal. Other good components connected at the terminal are protected from heat using old medical

clamps (hemostats). Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

Since almost all of the original parts were still in place I decided to try

to maintain the

original chassis appearance to the extent possible. Normally I rebuild all original wax-paper capacitors as well as the filter capacitors in

their original cases (restuff them). Both filter capacitors were still intact and could be

restuffed.

Repairs

One must be VERY CAREFUL when doing repairs in the area of the

band switch. The leads from the antenna and oscillator coils to the band

switch are hair thin and very fragile! There are several capacitors in the area

which have to be changed. Before starting repairs I took photos of the

chassis, top and bottom, so that the original component placement and lead dress

could be maintained.

Wiring

The first IF amplifier grid cap lead was worn and could short

to the transformer shield. This lead was replaced. To do so, the grid cap

was removed and the transformer shield removed. The transformer itself and

associated wiring was left in place. The grid lead was replaced using

green stranded hookup wire. The new lead was left long so that it could be

routed through the small hole in the top of the transformer shield as the shield

was being replaced. The shield was reinstalled, the lead cut to the

correct length, and the grid cap reinstalled.

The speaker cable (3 leads) was very stiff and there were

breaks where the cable passed though a hole in the rear chassis. The

clearance hole had no fiber grommet, unlike the hole for the power cord.

Perhaps it had broken. A vinyl grommet was installed just in case. The

speaker cable was removed from the radio and pulled out toward the front of the

chassis. The knot was undone and the cable leads straightened. I

used a heat gun on the cable to make it more flexible during the straightening

process. The leads were separated and patched using shrink tubing. The twist and

knot were restored and the cable reinstalled in the chassis, passing through the

vinyl grommet for some protection.

The line cord was replaced by a new brown vinyl cord with

molded plug. The original cord was a darker brown rubber.

Wax/Paper Capacitors

Three original Philco paper-wax capacitors had been replaced (parts 24, 28,

and 38 - all associated with the volume or tone control). I collect branded (Zenith, Philco, Sprague,

RCA/GE etc.) dud capacitors just for cases where an original

part has been replaced by a modern part. I was able to find the correct original

Philco part for 24 and 28 in my dud stocks. I did not have the correct original Philco part

for 38 (30-4467, .006mfd/600 volts), so I used Philco part 30-4591 (.006/400 volt) to

replace it. All paper-wax capacitors were restuffed using 630 volt film

capacitors. Capacitor 30 had been moved to the opposite side of the

chassis. After restuffing it was returned to the location shown in the

parts placement diagram.

My re-stuffing process is as follows:

- The original capacitor is removed from the radio, and the required lead

length and any insulating sleeving use noted.

- The low melting point wax from each end of the original or replacement

capacitor is melted and removed using an old

25 watt soldering iron.

- The original wire leads are removed, as well as any remaining wax.

- While the internal wax is still molten, a small screwdriver is used to push out the

original paper-foil roll. In some cases, the contents comes out when the leads

are pulled out.

- The original cases are then cleaned out, and any wax and dirt on the

outside removed by gently heating the body over a small alcohol lamp and

wiping with a paper towel while still molten.

- If the required lead length is longer than that of the replacement

capacitor, a piece of buss wire is attached before restuffing. The splice is

hidden inside the tube.

- The replacement capacitor is wrapped in a narrow strip of

paper towel in order to keep the new capacitor centered and to keep it from falling out.

- The finished capacitor is then sealed with melted rosin salvaged from

early RCA Superhet catacombs, and donated by or purchased from members on Antique

Radio Forums. I do NOT recoat the outside of the rebuilt

capacitors with wax (I'm not sure what was originally used - probably

beeswax).

Some original capacitor values are no longer available. In these cases I used

the closest current value. I did not try to use multiple capacitors to get

closer to the original values, since there was no room inside the original

case. For C40, 0.008mfd I used 0.0068mfd. For C38, .006mfd I used 0.0056mfd.

For C37, .03mfd I used .033mfd.

Filter Capacitors

The original power supply filter capacitors 11/11A and 45 were removed and restuffed.

Part 45 (30-2219A) was a 25mfd 475 volt wet electrolytic. It was restuffed

using a 22mfd/450 volt axial tubular electrolytic. My restuffing process for

this capacitor is as follows:

- The capacitor was mounted in my small Unimat lathe by holding the bottom

end in the 3-jaw chuck and retaining the opposite end using the lathe's live center

(centering it so as to ensure smooth rotation).

- The case was scored about 1" above the screw base (so that the

cardboard insulating cover would hide the joint). I finished

the cut with a fine tooth hobby razor saw - since these types of capacitors may still

have liquid electrolyte inside! In this case, the capacitor was dry.

- The center electrode was removed as well as the deteriorated rubber insulation and

external terminal lug.

- I used a small wooden spacer to replace the insulation. I had to

slightly enlarge the crimped end of the capacitor in order to insert the

spacer. For this, I used a succession of drill bits in my drill press. I then installed a long 6-32 machine screw from the terminal end,

through a solder lug, some fiber washers, through the spacer, through some

additional fiber washers, another solder lug, and finally a 6-32 nut.

The head of the machine screw was ground down so as not to be obvious.

The flattened screw head was then soldered to the outside solder lug, now

serving as the positive terminal.

- The plus lead of the replacement capacitor was attached to the internal

solder lug.

- The negative lead of the replacement capacitor was extended using solid

bus wire and insulating spaghetti tubing through a small drilled hole in the base

of the capacitor near the location of the original negative grounding lug.

- The two halves of the case were then reattached using 3/4" PVC

plumbing couplings and epoxy. If the cut is done cleanly, the cut is

hardly visible after reassembly. I had to add many layers of masking

tape around the PVC coupling to take up excess space.

- Once the epoxy has hardened, the original grounding lug and cardboard

insulator were reinstalled. The negative lead of the replacement

filter capacitor was then attached to the grounding lug. The cardboard

insulator completely hid the repair.

The process I used for restuffing the dry type capacitor 11/11A is similar to

the process used for part 45. However all of the contents have to be

removed, which is a messy and difficult process. I used a spade bit in my

drill press to remove most of the material. This capacitor is a dual dry type

capacitor with wire leads: 8mfd/475 volts and 4mfd/350 volts. It was restuffed

using a 10mfd/450 volt and 4.7mfd/450 volt electrolytic. The original

leads were cut, so they were replaced using the original wire colors. The

replacement capacitors were secured in the case using hot glue. The two halves

of the case were reattached with 3/4" PVC couplings as described above.

In this case no masking tape was needed, since the capacitor diameter is smaller

and the PVC coupling was a snug fit.

Resistors

One section of the three section wire wound resistor 43 (Candohm

type) measured 37% high and the resistance was unstable (it changed when the

lugs were moved). The remaining two sections were OK. This resistor is

used to provide bias voltages. I have found that these metal clad resistors

often respond favorably to clamping pressure near their terminals when a section

is unstable or has high resistance. I sometimes use a small C-clamp and

firm pressure on the metal housing on both sides near each terminal. In

this case, there was no way to use this method. I was forced to remove the

resistor from the chassis and apply pressure on both sides of the terminals

using my large bench vice. Each terminal is simply a band around the resistance

element, which is wound on an insulator. Over time, the band expands or

the insulator shrinks, resulting in an unstable, high resistance, or sometimes

an open section. In this case, after squeezing, all sections were almost

exactly correct and were stable (resistance did not change when the terminal lug

was moved)! Compressing the metal case applies additional pressure from

the band onto the resistance element. There is some risk to this

procedure, since the fish paper insulation may be damaged in some cases,

resulting in a short. For this reason, many collectors never re-use a

Candohm resistor in a restoration, even when good! Instead, they remove

the resistor and install terminal strips and individual wire wound resistors.

This of course greatly alters the under-chassis appearance of the radio. I

would also replace a Candohm resistor, and especially if part of it was bad, if

being PAID for a restoration. But this radio will be a keeper (which will

rarely if ever be played). And should the resistor eventually fail due to a

short or open, no major components would be damaged - the radio will simply stop

playing.

Resistor 12, a 10K 3-watt dogbone type resistor was out of

tolerance. I keep a stock of NOS and used "dogbone" resistors, and buy

all I can on eBay and radio swap meets! Of course, most of these

resistors, even NOS resistors, have also drifted in value and no longer have

their marked values. My solution is to find a replacement resistor of the

correct value and size as measured (ignoring the markings), and then repaint it

to the needed value codes using enamel hobby paint! In this case, I used a

6.2K 3 watt dogbone resistor that measured 9.24K. It was repained using

enamel hobby paint.

There were four carbon composition resistors also out of

tolerance. They are specified as 1/2 watt and are quite unique in appearance.

They are very close to the size of modern 1 watt carbon resistors. So I replaced

them with modern 1 watt carbon resistors and repainted them to match the Philco

color code scheme, which is body (1st digit), end (2nd digit), and a strip

(multiplier). In some cases, the body and stripe are the same color and no

stripe is used (490K). In other cases, the body and end colors are the

same (99K). I have always thought that Philco used these weird values in order

to avoid having to use a third color!

Here are the repainted reproduction resistors:

Tubes

The shield bases for the 6J5G and 6K5G were severely mangled in

order to install GT type tubes:

These were straightened as well as I could without removing the

shield bases, which would have meant drilling out the rivets. Fortunately,

the tube shields completely hide the damage. G type tubes were installed for the

6A8G, 6J5G, and 6K5G. The 6F6G was replaced (General Motors brand). The

original 5Y4G and 6K7G were good and were reused.

Tuning Capacitor

The dial assembly and tuning capacitor were removed for

cleaning, replacement of the rubber suspension parts, and repair of the

reduction drive. The two-speed reduction drive mechanism was removed from the

front of the capacitor. The trimmer capacitors and all associated hardware

(including the mica sheets) were removed before cleaning so that all parts could

be cleaned, and to avoid damage. The capacitor was then cleaned in my old

Heathkit ultrasonic cleaner using dilute ammonia. This has to be done in

several steps since the entire capacitor will not fit in the tank. Once cleaned,

it was rinsed and then cleaned with soap, water, and old toothbrushes and dried

using a heat gun.

As found, the anti-backlash gearing was damaged and was

preventing rotation of the tuning capacitor rotor. Originally there were two

driven gears. One was attached to the rotor shaft. The other was

free to rotate on the shaft. There were two small springs positioned between the

gears which put rotational pressure on the free gear so as to take up any slack

between the driving and driven gears. This reduced backlash in the

mechanism. Unfortunately, both springs were out of place. There was no way

to re-position the springs. One of the two was jammed between the two

gears. This spring was removed so that the tuner could rotate without

jamming. Unfortunately, this removed the anti-backlash function.

The reduction drive was gummed up with hardened grease and

difficult to turn. It was disassembled and all parts cleaned using lacquer

thinner, Q-tips, and pipe cleaners. It was very difficult to remove the three

ball bearings and spring from the assembly. Once all parts were removed and

cleaned, the parts were lubricated using automotive distributor cam lubricant

and reassembled. It then worked perfectly after its correct position on

the tuning capacitor was determined - the small driving pinion must engage the

driven gears on the tuning capacitor shaft correctly without excessive pressure.

The tuning capacitor rubber supports were replaced using part

PHS-38-10 available from Renovated

Radios (set of three). I also ordered the four chassis corner supports at

the same time (PHS-COR).

Testing and Alignment

Once the radio had been reassembled,

the radio was powered up slowly using a fused Variac. This allows the

filter capacitors to reform. A DVM monitored the B+ voltage. The radio came alive and

actually worked on both bands. The set was then aligned. The IF transformers were way

out of adjustment.

The radio worked well and sounded great with its large

electrodynamic speaker, large cabinet, and loudness compensation type tone

control. The set seemed to perform

best with a 6' length of wire for an antenna! It did not seem happy using my 40'

indoor antenna strung across my basement ceiling.

Cabinet

The cabinet was vacuumed then cleaned using GoJo (white) hand cleaner and 00

steel wool.

Restoration Results

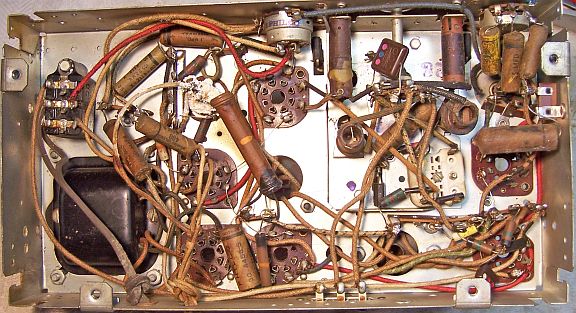

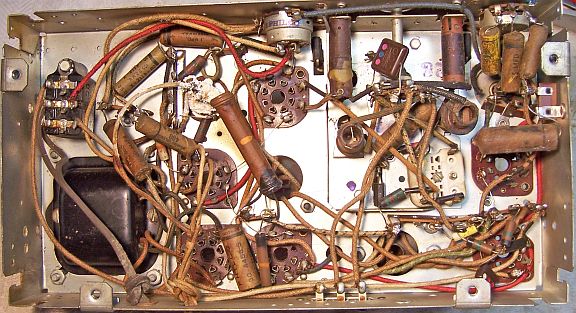

Chassis Before Restoration

|

|

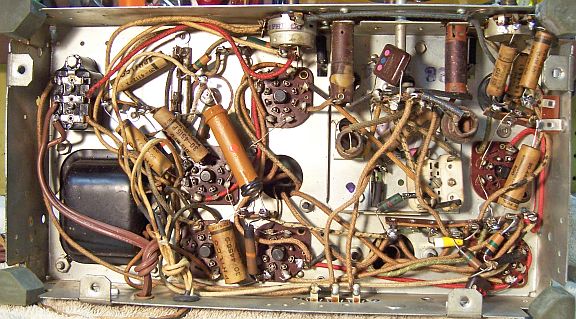

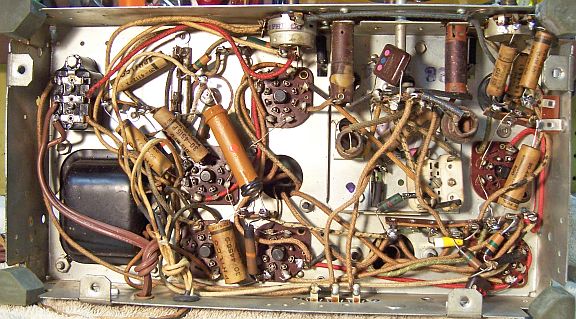

Chassis After Restoration

|

|