Silvertone Model 1938 Restoration

|

The Silvertone model 1938 from about 1936 is a 6-tube small

tombstone or upright style radio. It receives the standard broadcast

band and two short wave bands. This example had seen

minimal servicing in the past. I

decided to try to reverse any previous repairs and to retain the existing

above and below chassis appearance to the extent possible, and yet get it

working again.

The schematic for the Silvertone 1938 can be found on Radiomuseum.org. Any part numbers will refer to numbers on that

schematic (there is also a schematic on Nostalgia

Air, but the Radiomuseum schematic is more accurate). |

My

antique radio restoration logs

Condition As Found

This radio was purchased on eBay. The cabinet was in fair original condition, as were the

knobs and grille cloth - lots or wear, dings, scratches and finish loss.

The finish was cloudy or oxidized in areas. The top of the radio may have

been recoated with a dark stain or varnish. The radio was very dirty and dusty when

received - the dirt hid a lot of defects not visible in the eBay photos! There were a few nuts and

nut fragments inside, which was a bit worrying - this is often an indication of

rodent activity. However, there was no signs of any nesting, urine stains

or damage found. There was a fair sized

veneer chip on the top front. The

radio was sold as not tested. There was no external evidence that the radio had been

restored - even the power cord and plug were original. I always avoid knowingly purchasing a radio that has been

restored, as many collectors take shortcuts such as removing the original capacitors and filters. The original

final inspection tag was still attached to the speaker cable.

Circuit

The Silvertone model 1938 is a 6-tube AC superhet circuit radio,

and the circuit is very unusual. This is one reason that I purchased it.

It was manufactured for Sears by Colonial

radio, and the build quality was quite high. The radio has no RF amplifier, but does have a

double-tuned pre-selector (3-gang tuning capacitor) to reduce image response due to the

low IF frequency used (175kHz). The volume control system is very unusual: it varies the coupling between the primary and secondary of the

second IF transformer! I have seen this variable IF coupling used in other Silvertone radios

for variable selectivity or for tone control, but never before for volume control. Here

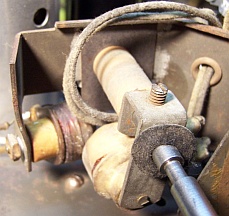

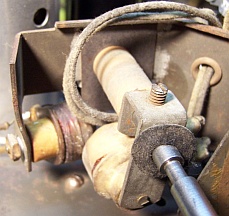

is the mechanism:

A sixth tube is used as a separate AVC stage - the

second detector and AVC functions are separate tubes. The signal level to

the second detector is varied by the volume control, but the AVC rectifier is

driven from the primary of the second IF transformer and thus is not affected by the

volume control. If this were not done, then reducing the volume would

reduce the AVC voltage and allow the radio to overload on strong signals. So in

reality, the weird and complex volume control method costs an additional

tube. The tube complement

is also unusual: a mix of standard base (big pin) tubes (84/6Z4, 75, 6A7) and

octal metal-glass tubes (6C5MG, 6K7MG, and 6F6MG).

Previous Repairs

-

The 6C5MG AVC tube had been replaced with a metal 6C5. The

6F6MG had been replaced by a 6F6G. The Silvertone 6K7MG tested weak but may

have been original to the radio. The remainder of the tubes were

likely replacements, since they were not branded Silvertone.

-

All paper capacitors were original (Sprague branded).

-

All resistors were original (all were dogbone style)

-

Two tacked in tubular electrolytic capacitors had been

installed under the chassis and were connected to the original filter capacitors, which were

still in place.

-

There was a small piece of metal (a shield) covering part of

the fixed secondary coil of the second IF transformer (which is part of the volume

control mechanism). Perhaps this was to reduce the coupling?

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major or unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise. I

did not test the radio prior to restoration.

-

The speaker field and output transformer were OK

-

The power transformer was OK. The high voltage was balanced across the center tap (with

20 volts applied through a Variac) and power consumption was very low (about

5 watts) with full line voltage and no load.

-

The tuning capacitor mounting grommets were OK - unusual.

-

The chassis mounting bushings were bad - which is almost always the case. One was intact

and could serve as a model to find replacements.

-

All except three resistors had drifted and were now out of tolerance. All were

dogbone style - most were 1/4 watt size.

-

All RF coils were OK

-

The first IF transformer was OK.

-

The primary of the second IF transformer at first measured OPEN, and

later measured a high resistance (1300 0hms). This coil is part

of the volume control, which varies the coupling between the primary and

secondary of the second IF transformer, and if defective would be a

showstopper to restoration! I connected a 1.5 volt battery to the coil through a DVM

set for measuring current. The current indicated a calculated resistance in the 50 ohm

range, which was correct. I then measured again and this time it

indicated about 55 ohms. I suspected a bad connection or the coil was

simply fooling my DVM's ohms measuring circuit.

-

The 6K7MG tube was weak. The remainder of the tubes were good,

although not the correct types in some cases.

-

The AC switch (on the tone control) was not functional - dirty or oxidized

contacts were likely.

Repairs

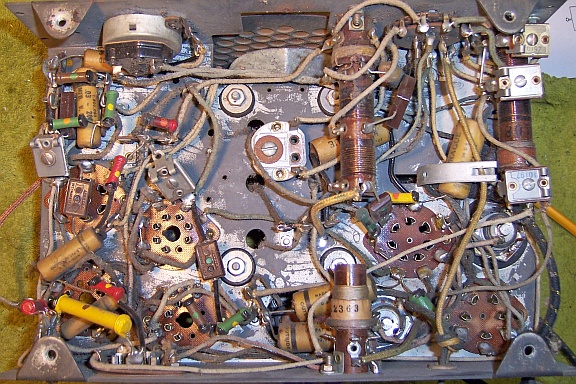

All tubes and shields were removed. I removed the tacked in filter

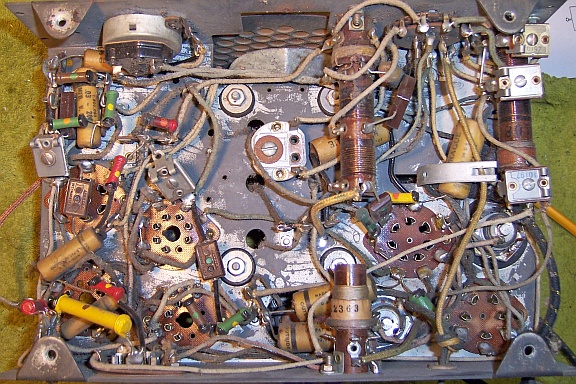

capacitors. I then took

a photo of the chassis

bottom so that routing of wiring and component placement could be restored.

Lead dress is often critical in radios. Since no parts had been replaced,

this photo should represent the original condition of the chassis, and thus the

desired appearance after restoration:

The dust was removed from the chassis using an air compressor. The dial

assembly and tuning capacitor were removed. The top of the chassis was cleaned with GoJo hand cleaner and 00 steel

wool. This process often leaves behind metal fragments which can cause

shorts, so I then went over the chassis with a small magnetic screwdriver to

retrieve them. The tuning capacitor (previously removed) was cleaned in an old Heathkit ultrasonic

cleaner with dilute ammonia. After drying, the bearings were lubed with

automotive distributor cam lubricant.

Resistors and Capacitors

All of the original Sprague paper capacitors were rebuilt in their original cases

using modern 630 volt film capacitors in order to maintain the original

under-chassis appearance. I reseal the cardboard tubes using rosin

salvaged from servicing RCA Radiola Superhet catacombs (it melts at a low temperature and will not damage

the replacement capacitors. When I replace a component, I

always remove the original part (or wiring stubs left over from past component

replacement) completely from a terminal. Other

components connected at the terminal are protected from heat using old medical

clamps. Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

The original filter capacitors C9 and C20 were rebuilt in their original cases.

Both were originally 8mfd wet electrolytics. Both were now completely

dried out,

which is why they could be left in place (and paralleled with new capacitors)

with no problems. C9 had a cardboard insulating cover, since its case is

not grounded. The cover seemed firmly attached to the aluminum can -

likely glued. In a previous similar situation, I split the cover and was

able to remove it with minimal damage, although the split was very visible. This one had a

top cover in addition,

which also did not want to come loose and would prevent removal of the bottom

part of the cover. If the covers were firmly glued in place, they would be

destroyed by any attempt to remove them. So I decided to leave the covers

in place. Both capacitors were chucked into my small Unimat lathe using

the original mounting nuts from both units to hold them in the chuck (the nuts were installed

back to back). The capacitor terminals would otherwise have prevented

mounting them in the lathe. A live center was used to steady the other

end of the capacitor. The cases were scored deeply about 1" up from

the bottom of the cases - almost all the way through - and then the cuts were

completed using a hobby fine tooth razor saw. The positive electrodes were

removed down flush to the insulator. The cases were then cleaned

inside. The existing positive electrode stubs were drilled and tapped for a 6-32

screw and a ground lug attached inside the capacitor. The positive lead of

the replacement 10mfd 450 volt axial electrolytic capacitor was attached to the

ground lug. A small hole was drilled into the base adjacent to the threaded stud

for the negative lead of the replacement capacitor, which was extended and

insulated using spaghetti tubing.

Tubes

I was able to find replacement Metal-Glass tubes for the 6K7MG (which was

weak) and the 6C5MG (which had been replaced with a normal metal 6C5). The

only available 6C5MG I could find had about 30% of the paint missing! I

later found a 6F6MG and installed that tube.

Other Repairs

The tone control and switch was cleaned with GC Big Bath cleaner. The

switch then worked OK. The band switch was also cleaned using Big Bath.

The chassis washers were replaced using Silvertone chassis mounts (GS-1954)

purchased from Renovated

Radios.

Testing and Alignment

Once the radio was reassembled and the tubes installed, power was brought up

slowly using a variac. AC power consumption was monitored using a watt meter, and a

DVM monitored the B+. The radio powered up and the audio worked, but

there was no reception. It was discovered that the replacement 6K7MG tube had died -

the filament was open, even though the tube tested good when received from the

vendor. I reinstalled the original 6K7MG that came with the set, which

tested weak, but it worked OK. Later, I resoldered the pins of the

replacement 6K7MG, and it then tested OK.

The set was then aligned. There are NO oscillator adjustments on this

radio other than a broadcast band padder. The two short wave bands were very

close to correct dial calibration. But the broadcast band was about 50kHz

high. There was not much I could do about this.

The variable IF coupling volume control moving coil was returned to its as

found position. At minimum volume, there was still some sound heard.

I temporarily reinstalled the aluminum shield that was found originally

installed on the radio. It did reduce the minimum volume considerably, but was

very likely NOT original. There were instructions for improving minimum

volume performance found in Riders. This procedure was followed and the

result was satisfactory (but there was still some sound output at

minimum volume!)

There was severe modulation hum and resulting distortion on stations at the high end of the broadcast

band. There was no problem on the short wave bands or on the low frequency end

of the broadcast band. This is a common problem in my shop. My antenna is

indoors (strung from the basement ceiling), and there are lots of sources of interference, such

as electrical wiring, fluorescent lighting fixtures, wall wart power supplies,

computers, and other devices. Some radios have this problem, while others

do not. Zenith radios with shielded Wavemagnet (loop) antennas never seem

to have the problem. In the past, I have been able to eliminate or reduce

the problem by grounding the radio, moving it away from my work bench, reversing

the AC plug, installing a line bypass capacitor, or simply rotating the radio 90

degrees. But nothing seemed to work with this radio! The best cure

seemed to be connecting a 0.1mfd capacitor between the hot AC lead and ground

(center screw of a grounded electrical outlet). I was getting inconsistent

test results until I realized that the original line cord and plug were NOT

polarized, and thus reduction of modulation hum depended on which way the radio

was plugged in. I permanently installed a 0.1mfd 630 volt capacitor

between one side of the AC line and the chassis, and always ground the radio

when in use. This resulted in acceptable performance if the radio is

plugged in a particular way. Ideally there would be a line bypass

capacitor from both sides of the AC line to ground (chassis). However in

this case, one end of the AC line is directly connected to one lead of the power

transformer using a taped joint, and is thus not accessible without wrecking the

originality. The taped joint was also directly underneath one of the RF

coils. If I ever sell this radio, I will have to

remove the capacitor, since a user could get quite a tingle if he/she touches

the chassis that is not grounded!

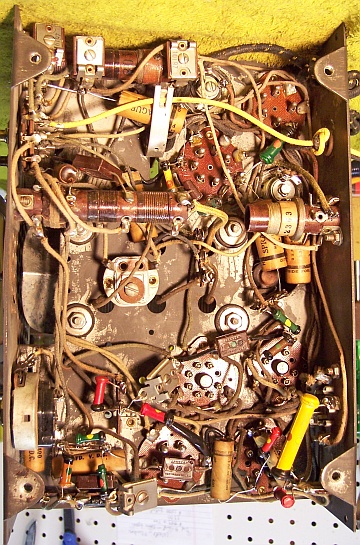

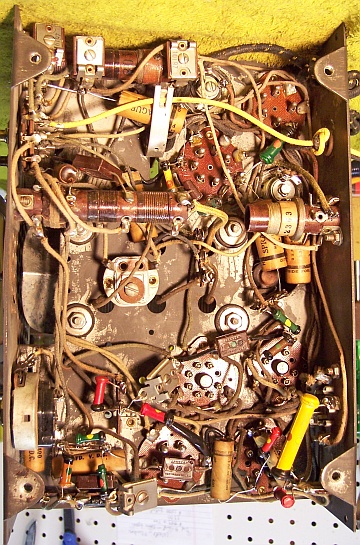

Restoration Results

Non-original line bypass capacitor is not shown. The 6F6G tube has been replaced by a

6F6MG in the next to last photo (back view).

|

Chassis Before Restoration |

Chassis After Restoration |

|

|