Truetone (Wells-Gardner) Series 7J Tombstone

|

The Truetone Series 7J is a large 7-tube AC Superhet

circuit radio that receives the broadcast band and one short wave band.

Truetone was a brand sold by Western Auto Supply. This particular radio

was made by Wells-Gardner (W.G. 24). The radio had seen some servicing in the past.

There was a radio shop label still on the cabinet. Three wax-paper capacitors

had been replaced, the power cord replaced, and some tubes likely had been

replaced. Since the radio was still largely original, I decided to try to

get it working yet maintain the

original top and bottom chassis appearance and to reverse any previous

repairs to the extent possible.

The schematic for the radio can be found on Nostalgia

Air. Any part numbers will refer to numbers on that schematic. |

My

antique radio restoration logs

Overview

This radio was purchased at the 2014 CC-AWA Antique Radio Conference and

Flea Market in Charlotte, NC. Being made by Well-Gardner, the build quality is very high. The working status was not stated by the seller. The cabinet

finish, grille cloth, and knobs were original and in good condition. All

tubes and tube shields were in place. The often missing chassis retainers

(L-shaped and threaded) were in place, as were the chassis cushions. There were

no shipping bolts present.

Previous Repairs

The radio had seen a minimal amount of repair in the past, and

all repairs were far in the past, judging from the vintage of the components used. This

was a well loved radio that someone paid a lot to have repaired.

-

Three wax-paper capacitors had been replaced. In this radio

this is a difficult task, since all tubular wax-paper capacitors are secured

by clamps (fortunately held by screws rather than rivets).

-

The original filter capacitors were still in place.

-

It is likely that some or perhaps all tubes had been

replaced. Three were branded Wizard, three branded RCA, and one branded

Philco. The Wizards may have been original.

-

All of the original resistors were still in place.

-

The line cord had been replaced.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise. I

never apply power to an unrestored radio, even through a variac or "dim

bulb" tester.

-

Seven resistors were out of tolerance (more than +/-20%). All were

old style dogbone

type resistors of various wattages.

-

The speaker cone, field coil, and output transformer were

OK.

-

The power transformer was OK. The high voltage was

balanced across the center tap with 20 volts applied through a variac.

With full power applied (no tubes present), the wattage consumed was less

than 10 watts. A transformer with shorted turns will draw excessive

power and will heat up. I use a real analog watt meter for these

tests.

-

One pilot lamp socket was missing (the power lead was still

in place).

-

The wire wound resistor R13 was fortunately good and in

tolerance.

-

All RF coils and transformers were OK.

-

The IF transformers were OK.

-

All tubes were good.

-

The chassis cushion washers still OK.

-

The tuning capacitor mounting grommets had hardened and

shrunk, allowing the capacitor to move around.

-

All wiring was cloth covered and was OK.

-

All tube shields were present.

-

The pilot lamp was burned out

Repairs

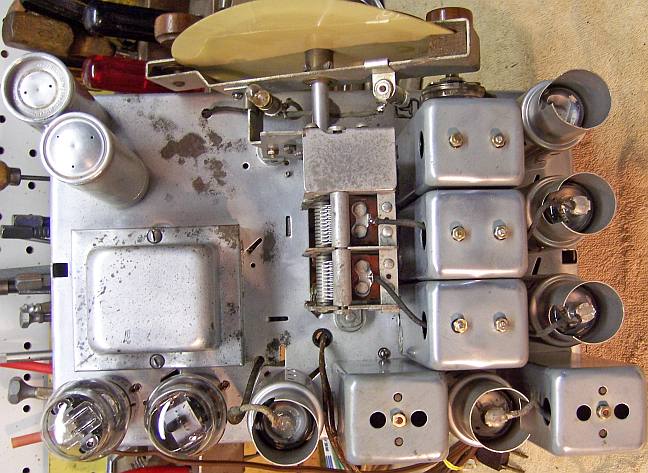

The chassis was very dirty. All tubes and shields were removed and dust was removed using an air compressor.

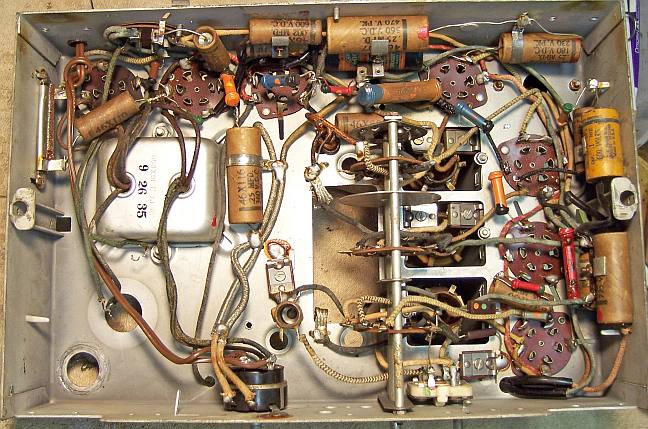

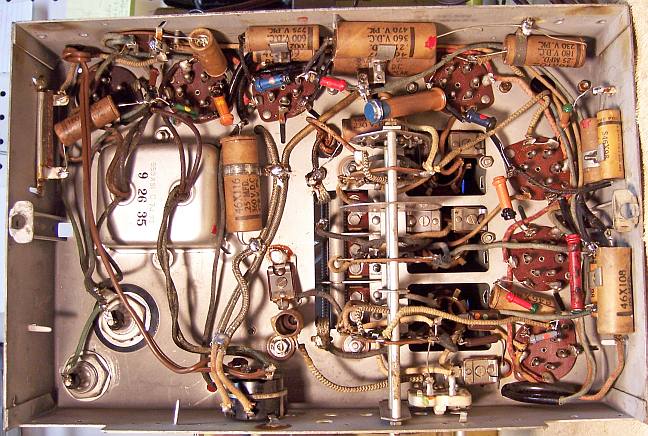

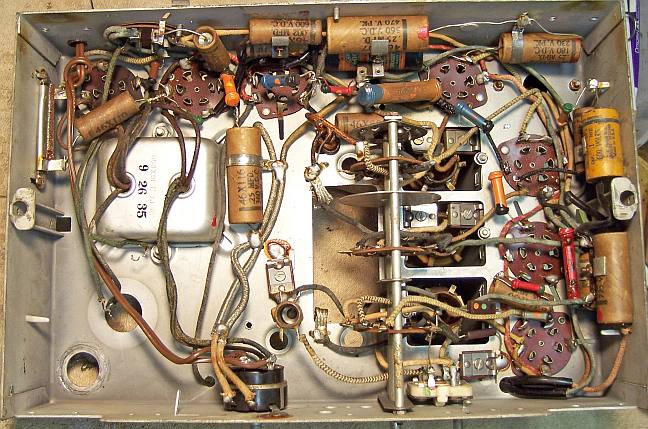

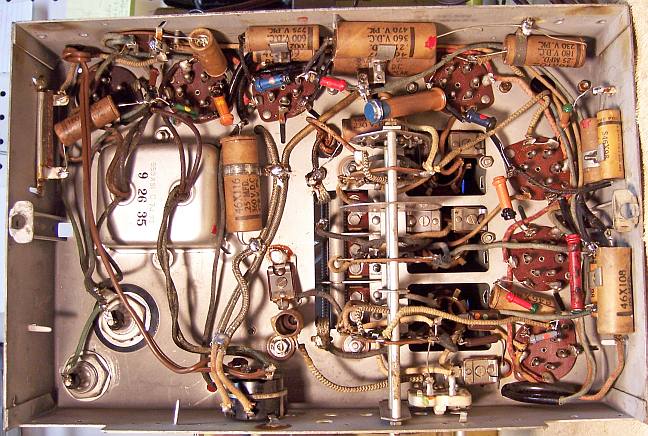

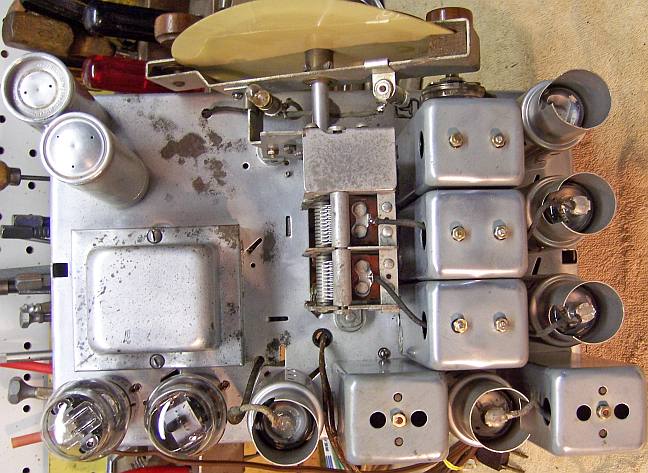

Before starting repairs, I took photos of the chassis bottom so that routing of wiring and component placement could be restored.

Lead dress is often critical in radios. The tuning capacitor was

removed for cleaning and for replacement of the mounting grommets. The two

can type filter capacitors were removed for restuffing and chassis access for

cleaning.

I then removed all

of the non-original capacitors, documenting their locations

and connections. When I replace a component, I

always remove the original part completely from a terminal. Other

components such as mica capacitors and in-tolerance resistors connected at the terminal are protected from heat using old medical

clamps (hemostats). Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

The top and sides of the chassis were cleaned with GoJo hand cleaner and 00 steel

wool. Since this process may leave metal residue, I then went over the

chassis with a vacuum cleaner followed up by a small magnet and masking tape.

The tuning capacitor trimmer hardware and mica insulators were removed to

prevent damage during cleaning. I noted the original positions of the trimmer

adjustments so that they could be returned to the original positions. I do this

by counting the number of half-turns of the adjustment screw to fully tight. The tuning capacitor was

cleaned using in my old Heathkit ultrasonic

cleaner using dilute ammonia, followed by soap, water, and old toothbrushes. After drying, the

bearing surfaces were lubed with automotive distributor cam lubricant. The tuning capacitor grommets were replaced by

GLg-Tuner grommets from Renovated

Radio, thick side up. These worked OK, but the center hole was

slightly large and allowed some movement of the capacitor. These grommets

were also slightly too short, so flat washers were added between the capacitor

body and the grommets.

Capacitors

Filter Capacitors

The original wet type filter capacitors were still in place. One (C25,

14mfd/400 volts) was insulated from the chassis. The other (C26, 18mfd/300

volts) was not insulated from the chassis. I was able to remove C25 easily

using a large socket wrench. But the threads on C26 were stripped and I was NOT

able to remove the part. I was forced to cut off the body and then grind

off the remainder of the capacitor. I found a similar part in my junk box

to replace it. Both capacitors were restuffed with suitable new

electrolytics. I used 15mfd/450 volts for C25, and 22mfd/450 volts for

C26.

Here is my restuffing process for these wet type electrolytics:

- The capacitor was mounted in my small Unimat lathe held in the 3-jaw chuck

by its mounting nut and secured on the opposite end by my live center.

The capacitor is held by the nut to prevent damage to the threads.

- The case was deeply

scored about 1" above the base (almost through the case). I

finished the cut with a fine tooth hobby razor saw. In this case, there was

no liquid inside to be slung out as the capacitor was turned in the lathe. If the cut is done cleanly, the cut is

hardly visible after reassembly.

- The center electrode foil was removed, but the aluminum center stud was

retained and cut short. A hole was drilled into the center stud and a

solder lug was attached using a 4-40 brass screw and nut.

- The plus lead of the replacement capacitor was attached to the solder lug.

- The negative lead of the replacement capacitor was extended using solid

bus wire and insulating spaghetti tubing through a drilled hole in the base

of the capacitor near the threaded mounting stud.

- The two halves of the case were then reattached using 3/4" PVC

plumbing couplings and epoxy. I normally add a few layers of

masking tape around the PVC coupling to take up any excess space.

- Once the epoxy had hardened, the original grounding lug and insulators

were reinstalled. In the case of C25, the negative lead of the replacement

filter capacitor was attached to the grounding lug after the capacitor was

mounted. In the case of C26, the negative lead was trapped between the

capacitor body and the chassis.

Wax-Paper Capacitors

All the wax-paper capacitors in the radio were marked with a part number

starting with 46X, and also marked with the value and voltage rating (normal and

peak). The capacitors used by Wells-Gardner are unusual in that their voltage

ratings are values such as 180, 240, or 360 volts etc. Their construction is

also unusual. The capacitor is assembled inside a cardboard tube, the ends of

which are crimped. Inside both ends is a metal disc, to which the component

leads are soldered. The foil roll is soldered to an extension of each lead on

the inside. The tube is filled with wax (and in one case, with tar). These

capacitors are difficult to restuff without the repair being visible. There is

really no way to "uncrimp" the ends without making a mess. My

restuffing process is as follows:

- The original lead length required is documented.

- One end of the cardboard case is removed using a sharp single edge razor

blade. The cut is done as close as possible to the end, and great care

is taken to keep the cut line straight.

- The cardboard case is then heated using a heat gun. The part is held using

pliers by the lead on the opposite end.

- While warm, the outside of the cardboard tube is wiped clean using a paper

towel.

- The case is held using a paper towel and the lead on the cut end is

pulled. This will remove the metal disc as well as one component lead

and will break the connection to the foil roll.

- The case is then again heated with the heat gun and the contents pushed

out from the opposite end (I use a small socket wrench for this purpose - it

is hollow inside to accept the component lead). The contents are then

discarded.

- The component lead on the cut end is cut flush with the metal disc, and

then unsoldered from the disc. The center hole in the disc is cleaned of any

solder so that replacement leads can be attached.

- If the lead length required is longer than those of the replacement

components, the leads are extended using buss wire. The splice is made

close to the body of the replacement part so that the splice will not be

visible.

- The metal disc previously removed in step 7 is inserted back into the

cardboard tube in its original orientation.

- The replacement capacitor is wrapped with a narrow strip of paper towel in

order to center it in the tube, then one end of the replacement capacitor is

passed through the center of the metal disc and soldered to the disc on the

outside.

- The cut end of the tube is then filled with melted rosin salvaged from

servicing RCA Radiola Superhet catacombs! Some collectors use beeswax

or even hot glue to secure the part in place.

Three original capacitors had been replaced: C6 and C21 (0.1mfd/360 volts)

and C9 (.25mfd/240 volts). I collect both branded (Zenith, Philco, etc.) and

generic dud capacitors. However I did not have the correct original

Wells-Gardner parts in stock. For C6 and C21 I used Wells-Gardner part number

S46X98 (.1mfd/180 volts) restuffed using 0.1mfd/630 volts. For C9 I used

part number 31077 .25mfd/400 volt restuffed using 0.22mfd/630 volts.

Resistors

All resistors in the set were old style dogbone types and were all original. Seven

resistors were out of tolerance by more than 20%. I maintain stocks of NOS

and used dogbone resistors, and buy all I can find that are

reasonably priced. I also NEVER throw away a used dogbone resistor, even

if out of tolerance. One resistor (R7) was inside the second IF

transformer shield can, and thus hidden. I replaced this one with a

standard 1/2 watt carbon resistor. For R2 and R8 I found NOS dogbone resistors

in my stock that were in tolerance. For the remainder, I found

replacements that were the correct size and in tolerance for the needed

values. These were repainted to the correct values using hobby enamel

paint.

Other Repairs

The missing pilot lamp socket was replaced by a similar part. The

original socket was screw based. The only suitable part I had in stock was

bayonet based. The extant power lead was reused. The missing shipping bolts were

replaced by 4" 1/4-20 carriage bolts. I think they should have been

5/16" diameter. The bolts were shortened by about 1/4" to prevent them

protruding from the bottom of the cabinet. I have never seen original

shipping bolts and nuts, since these are normally removed and discarded by the

original owners.

Cabinet

The cabinet was vacuumed and then cleaned using GoJo (the white type, not pumice) hand

cleaner and 00 steel wool. The grille cloth was simply vacuumed.

Testing and Alignment

Once the radio was reassembled and the tubes installed, power was brought up

slowly using a variac. A DVM monitored the B+. The radio came alive immediately and worked. It

was then aligned.

Restoration Results

Most of my restoration objectives were met, but not all. There was no

intention of restoring the set to factory new appearance! My objective is

usually to reverse any prior servicing and make the radio appear to have never

been repaired. I do not go so far as to artificially "age"

solder joints, as do some collectors! Here are some of my "misses":

- I did not have correct replacements for the three missing capacitors.

- The replacement pilot lamp socket was not the same type as the original.

- I left the original vinyl power cord in place. The original would have

been cloth covered.

Before and After Restoration Photos

Chassis Bottom Before and After Restoration