Zenith 4K402D (4-K-402D) Portable Restoration

|

The Zenith 4K402D (4-K-402D) Portable radio is a 4-tube dry

cell battery superhet circuit portable. It receives only the

broadcast band. The combination battery delivers 1.5 volts and

90 volts. The set has a built-in loop antenna, and can also accommodate

an external antenna and ground. The schematic for the Zenith 4K402D is on-line at Nostalgia

Air.

The radio had seen no obvious servicing in the past - all of the original parts were still in place.

My restoration objective was to maintain as much originality as possible

and yet get the radio working. |

My

antique radio restoration logs

Condition As Found

This radio was purchased on eBay, where it was advertised as

"unmolested", which was certainly true. All the original parts

were still in place, including the original Zenith branded "G" type

tubes (tall tubular types). This radio, and other Zeniths of this vintage,

used rubber covered wiring, which by now has crumbling insulation

(interestingly, only certain colors!). The

battery cable had been repaired using electrical tape to prevent shorts.

One of the two brass chassis retaining plates had been replaced with a flat washer

(indicating that the chassis MAY have been removed at some point), but no parts

had been changed. This radio uses the infamous "upside down bakelite

chassis" which was used by Zenith for a short period of time as a cost

saving measure. The chassis itself is the same as the one used in the 6-tube AC/DC

sets such as the 6D413, but two of the tube sockets are not used - one is

blocked off, and the battery cable is routed through the keyway in the other.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. I never apply power to a radio before

restoration. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise.

-

The power switch was bad (it measured a high resistance) - dirty and/or oxidized contacts

were likely.

-

The speaker cone was perfect.

-

The output transformer was OK.

-

All coils and the IF transformers were OK. Some of the coils used in this

radio are quite unique in construction, and difficult if not impossible to

repair or replace. If any of them had been defective, I would have abandoned the

restoration and sold the set for parts.

-

All the tubes tested good, and were likely the originals. Two of the

grid caps were loose.

-

Most of the wiring in the radio was rubber covered and the insulation would

fall off if disturbed. Some of the wiring could be retained, but the battery

cable was a total disaster, with electrical tape repairs. The battery

cable would have to be replaced.

-

All the resistors were the original dogbone types. A few were out of

tolerance. R2 (converter screen) was +22.55%. R6 (1st AF grid)

was +37% high, but would likely work OK (I have seen 15meg used in this

position in other radios). R7 (2nd AF grid) was +22.7%. I

decided to leave ALL of these in place until the radio could be tested.

-

One brass chassis retaining plate was missing, replaced by a large flat

washer.

Repairs

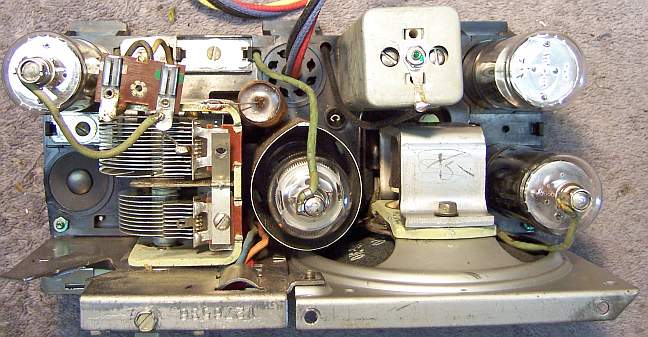

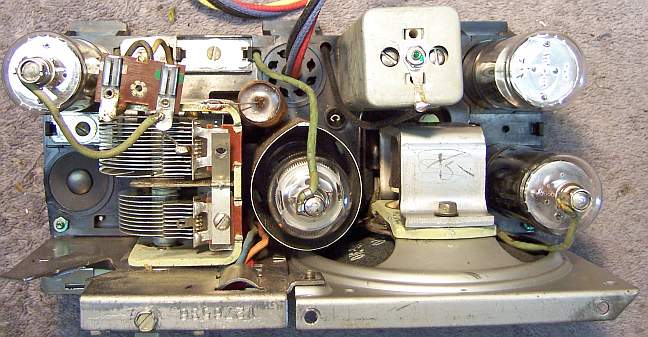

Before starting repairs I made a BEFORE photo of the chassis bottom. I use these photos to ensure that replacement parts and

wiring are placed as close as possible to their original positions. Some

radios are subject to problems (such as oscillation) if wiring is re-routed or

lead dress is not the same as the original. The oscillator coil and first

IF transformer are very fragile in this radio. There are no lugs or shield

cans for either! Each is attached to the bakelite chassis and wire leads

connected directly to various points on the chassis! These leads are very

fragile, and easily damaged in handling or repair.

Before even starting the survey, ALL the capacitors were removed from the

chassis. They would eventually be restuffed anyway. And removing

them would allow more accurate measurement of the resistors' condition, since

leaky

capacitors would prevent accurate measurement of high value resistors.

Also, the capacitors often covered buried components. As

each capacitor was removed, its value, the Zenith part number, connection points, and

original lead length was documented and its position noted on a photo of the

chassis bottom. A marking tag was attached to each, referencing my notes

on its removal. All original

Zenith paper capacitors were rebuilt in their original cases using modern 630

volt axial film capacitors in order to maintain the original under-chassis

appearance. I reseal the cardboard tubes using rosin salvaged from

RCA catacombs (it melts at a low temperature and will not damage the replacement

capacitors). The 8mfd/150 electrolytic capacitor was restuffed using

a 10mfd/450 volt unit.

The tubes were removed, cleaned, and tested. Two had loose caps.

These were repaired by cleaning the projecting wire from the top of the tube,

removing the solder from the cap (until the hole was visible), reattaching the

cap with epoxy (making sure the projecting wire from the tube projects through

the hole in the cap), and after hardening, the cap is fluxed and re-soldered.

The power switch (a slide switch) was removed from the set and cleaned in my

old Heathkit electrosonic cleaner, rinsed, and dried with a heat gun. It

then worked well.

The battery cable was then removed by first removing the electrical tape and

then the battery plug. This was done so that the cable could be removed

from the set intact and could be accurately measured for the length of each

wire. The retaining knot was then untied and each wire measured for its

replacement. I used cotton covered wire (unrated size, available from RadioSupply.Com)

in the appropriate color for the replacement cable. One loop antenna

connecting lead had broken off, and was replaced. The remaining wire was

left intact (I avoided any unnecessary movement).

Once the radio chassis was reassembled and the tubes installed, power was

applied through a regulated 1.5 volt and 90 volt supply (a modified PermaPower

unit with added regulation, which has the correct battery sockets to mate with

the radio's battery plug). The radio worked, but not very well. The

alignment adjustments were way off. Also, it was noted that the set broke

into oscillation as the adjustments were peaked. The problem was isolated

to a poor ground to the second IF transformer shield. The rivets holding

the shield to its lugs were apparently corroded, and not making a good

connection. And since this radio has a bakelite chassis, the shield ground

depended on ground leads soldered to the mounting lugs. I did not wish to

remove the IF transformer and replace the rivets, since that would risk damage

and also disturb the fragile original wiring, thus forcing its replacement. So

I simply attached a ground lug to the top screw and ran a ground lead to a point

which was connected to the metal chassis and the negative A battery lead.

The set was now stable and could be aligned.

Once working well, the set suddenly failed! The output transformer

primary had decided to open up. This could be a showstopper, since the

transformer is very small and must fit in a small cavity molded into the bakelite

chassis. The transformer case was riveted to the speaker basket. I first

disconnected the wiring and removed the speaker. This is not an easy task,

since one mounting screw passes through the chassis with its nut inside the IF

amplifier tube shield! I found a small output transformer in my junk box

that appeared small enough to work. I had no idea of its impedance ratio,

but decided to simply try it and see if it worked. But that transformer

also had an open primary! I performed some surgery and found that the

leads were no longer connected to the ends of the winding. I attached new

leads and soldered them to the primary winding ends, which were fortunately

still intact. The winding then measured 506 ohms DC - the original was

about 700 ohms. I removed the shell of the replacement transformer.

One rivet retaining the original transformer to the speaker basket was ground

off using a Dremel tool. The secondary leads were unsoldered, one leg of

the frame raised enough to remove the original core and coil, and the

replacement inserted. It did fit, although somewhat smaller than the

original. The frame (and a ground lug for the voice coil lead) was

reattached to the speaker from using a 6-32 screw and nut. The speaker was

then reinstalled in the set. The original transformer had two solder

lugs. The replacement only had wire leads. I simply ran these leads

to the appropriate points in the chassis (pins 3 and 4 of the 1C5G output tube),

removing the original leads that went to the transformer. Capacitor C8

(the quality capacitor) was relocated and connected directly to the 1C5G plate

and B+. Once retested, the set worked OK. I noted no difference in

performance with the replacement transformer.

After restoration was complete, I attempted surgery on the defective

transformer. I found that one winding lead had broken loose from a

terminal. This was repaired. I did not replace the transformer, but

kept it along with the two wires removed with the radio.

Cabinet

The cabinet needed a good vacuuming inside and then cleaning on the

outside with GoJo and 00 steel wool. A replacement chassis retainer clamp

was fabricated from scrap brass.

Restoration Results

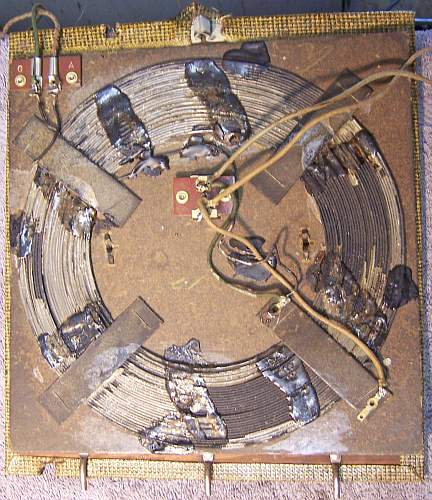

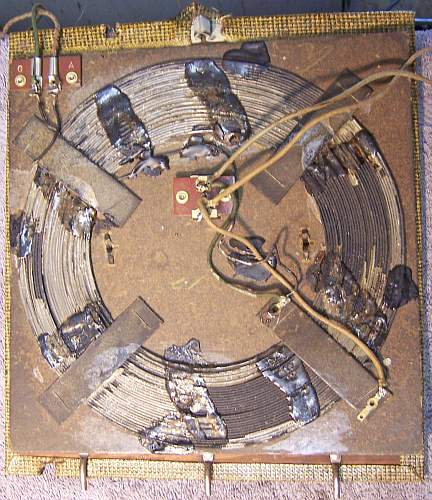

Chassis Bottom Before and After Restoration