Zenith 805 Cathedral Restoration

|

The Zenith model 805 Cathedral from 1935 is a small tabletop

5-tube AC superhet circuit radio. According to the Western

Historic Radio Museum, the Zenith 805 was the last cathedral style

cabinet made by Zenith. The radio receives the broadcast band and

one short wave band. The radio had seen

extensive servicing

and "electrical restoration" in the past - likely by a collector

- and was very sloppy work. As received, the radio did power up, but there was no reception. I

decided to try and restore the original top and bottom chassis appearance if

possible and to reverse previous repairs and restorations to the extent

possible. This turned out to be a real challenge!

The schematic for the Zenith 805 can be found on Nostalgia

Air. Any parts numbers mentioned will refer to numbers on that schematic. |

My

antique radio restoration logs

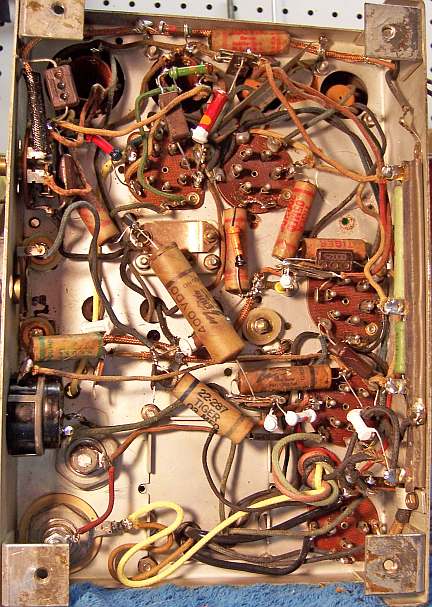

Previous Repairs

-

The grille cloth had been replaced.

-

The radio had been partially recapped, likely by a radio

collector rather than a service technician. Seven original Zenith

capacitors had been replaced. Capacitors that would have been difficult to

replace due to their location were NOT replaced. Many capacitors

were the wrong values and types, and some were not even soldered in (leads

just wrapped around a terminal or other component). For example, the

tone control capacitor (.03mfd) had been replaced by a .5mfd unit!

This high value would have surely killed most of the audio. The

oscillator feedback capacitor (.01mfd MICA) had been replaced by a paper

capacitor. New filter capacitors had been tacked in.

Fortunately, the original can type filters were still in place.

-

All the tubes were replacements.

-

Two goat type tube shields were missing.

-

Two power resistors were tacked in to repair two open

sections of the Candohm metal clad power resistor .

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise. I found:

-

All 11 original dogbone resistors were out of tolerance (by more than 20%).

Two sections of the Candohm wire wound resistor were open (5700 ohms and 11K

ohms). The bias portions (250 ohms and 85 ohms) were OK.

-

Only three original Zenith paper/wax capacitors were still in place, and

seven had

been replaced with capacitors of various types and sizes.

-

All tubes checked OK.

-

The output transformer primary was open (likely the reason the radio did not

work as received!) This may have been caused by the

"restorer" or repair tech installing a 0.5mfd capacitor as the

tone control capacitor (should have been 0.03mfd) which is from the output

tube plate to ground. Another possibility is that the original

capacitor shorted and took out the output transformer.

-

The power transformer, speaker field coil and all IF and RF transformers

were OK.

-

The IF amplifier cathode resistor looked original, and was 990 ohms (it had

drifted to 1125 ohms). The schematic and other information I had, as

well as other radios used for reference, indicated that the value should be

300 ohms. A 300 ohm resistor was installed. The 990 ohm value

may have been an official Zenith change.

-

The chassis washers were bad, which is typical.

-

The power cord had a break near the chassis entry grommet and one other place, but

was original. The plug was old style, but likely a replacement.

-

The power switch on the volume control was bad - likely corrosion or

dirt. The volume control itself appeared OK.

-

Some wiring, including the cable to the speaker, was in bad condition and

would have to be replaced.

Cleaning

One of the first things I noticed was that there was some sort of CRUD on the

top of the chassis and on some of the chassis top components (in the photo

below, the right side of the power transformer had already been cleaned).

This material was very hard and almost impossible to remove. I tried soap and water,

paint thinner, vinegar, ammonia and lacquer thinner. None of these would

remove it! Even a Dremel Moto Tool with a wire brush had difficulty.

I could remove it using GoJo hand cleaner and 00 steel wool, but with great

difficulty. There were lots of suggestions from the friendly folks on Antique

Radio Forums, but none of the suggestions helped. So I just continued

using the GoJo and 00 steel wool, manual scraping, and the Dremel. This

also removed the paint on the power transformer. I eventually removed all

chassis top components for cleaning (one at a time). The tuning capacitor

was cleaned in a dilute ammonia solution in an ultrasonic cleaner, followed by

soap and water and a tooth brush, then after drying, some wire brushing to

remove some of the rust. The power transformer case was wire brushed and

then repainted.

Repairs

Since the radio had been so badly hacked, an Antique

Radio Forums member was able to provide me with a mostly original 805 under chassis photo. This was used for component placement and routing of

wiring.

The volume control switch was flooded with Big Bath cleaner and cycled many

times. The switch eventually worked.

The open output transformer was replaced by a Stancor A-3850 8-watt universal

replacement transformer from my parts stock. This particular transformer

had one side of the primary OPEN. But this worked out OK since this radio

had a single-ended output stage. The speaker voice coil measured 3.1 ohms

DC resistance. I estimated the impedance as 3.4 ohms. The type 42

output tube needs a plate load of about 7000 ohms. So the required ratio

is 45:1. I was able to come close to this ratio using lugs 4-5 of the

secondary (47:1). The mounting centers of the replacement transformer was

the same as the original: 2".

I had the required TALL Goat tube shields in my stock. They had to be

cleaned up on a bench grinder with a wire brush to remove the rust.

All grid leads, as well as the speaker cable, had to be replaced. The

original power cord was cut at the chassis entry grommet and reinstalled. One bad

place in the cord was repaired using shrink tubing and electrical tape.

While somewhat unsightly, at least the original cord was saved.

For chassis washers, I used part CW-6 (1/8" thick) from Renovated

Radios. These placed the control shafts at the correct height.

For the tuning capacitor grommets, I used part GSm-Tuner with the smaller

diameter part sliced off using a razor blade (six needed).

Resistors and Capacitors

I have noticed that 1935-1936 (and possibly other) Zenith radios used

capacitors made by Sprague and Cornell Dubilier, but with Zenith part

numbers. Some were branded TIGER, but again, had Zenith part numbers

(22-xxx). Later on, all Zenith capacitors were orange in color and were

branded Zenith.

All original Zenith paper capacitors remaining in the radio were rebuilt in their original cases

using modern 630 volt axial film capacitors in order to maintain the original

under-chassis appearance. I reseal the cardboard tubes using rosin

salvaged from RCA catacombs (it melts at a low temperature and will not damage

the replacement capacitors). I collect original Zenith (as well as Philco

and other branded types) wax/paper capacitors for use when the originals are

missing. Zenith schematics in Riders Manuals indicate the Zenith part

numbers of the capacitors used. I was able to find the correct part

numbers for most of the missing original Zenith capacitors in my stocks.

In some cases I did not have the exact dud in stock, but did have a Zenith part

with the same value and voltage rating and a later part number. For

example, one original missing part n umber was 22-170 - I used a 22-170F which was the same

value but likely a later version. In all cases, these dud replacements were

restuffed with modern 630 volt film capacitors and then resealed.

A 0.01mfd 400 volt mica capacitor was installed for the oscillator feedback

capacitor (22-276). I did NOT have a Zenith part in stock this case - an Aerovox unit was

installed. Another 250pf mica capacitor was leaky (22-182, RF bypass

capacitor across the volume control). Again, an Aerovox was installed to

replace it.

The original filter capacitor cans (8mfd) were restuffed using new 10mfd/450 volt

capacitors. The cardboard sleeve was removed from the input filter

capacitor. The cans were then mounted in a Unimat lathe and deeply scored

about 3/4" up from the base. They were then cut in two using a hobby

razor saw. The contents were removed. The original center studs were

cut short, drilled, and a ground lug installed using 4-40 hardware. The + lead of the

replacement capacitor was attached to this lug. The negative lead of the

new filter was extended using bare buss wire to the base of the can where a

small hole was drilled. Insulating spaghetti tubing was used to prevent

shorts. The buss wire was later placed in contact with either the chassis

or the ground terminal of the filter capacitor. The two halves of the cans

were then rejoined using 3/4" PVC plumbing couplings and epoxy. This

makes for an almost invisible repair. The cardboard cover was reinstalled

on the input filter capacitor.

The eleven dogbone resistors that were out of tolerance were replaced by

either NOS dogbone

resistors that were close enough to the needed value, or with others that had

drifted to near the correct value. The resistors that had drifted were repainted using

enamel hobby paint

to the correct color codes. For example, one resistor needed was a 29K 1/2 watt

dogbone. It was replaced by a 20K 1/2 watt dogbone that had drifted to

31.46K, which is within tolerance. While these resistors may continue to drift, so will the others in the set. I wished to maintain the

original above and below chassis appearance. I collect all the NOS and

used dogbone resistors I can find, just for this purpose, and never throw one

away!

Less obtrusive power resistors were used to replace the open sections of the

Candohm metal clad power resistor. These were placed under the Candohm and

attached to the original terminals. The open sections were first checked

for leakage to ground and between terminals using a current limited 450 volt DC

source and a milliamp meter. The terminals are wiggled during the

test. If there is any hint of leakage or intermittent continuity, I would

instead install terminal strips and NOT use the original Candohm terminals.

Testing and Alignment

Once the radio was reassembled and the tubes installed, power was brought up

slowly using a variac. AC power consumption was monitored using a watt meter, and a

DVM monitored the B+. The radio came alive immediately and worked.

The set was then aligned. I noticed that if the IF transformers were

adjusted for best results, the set would break into oscillation. I had to

slightly detune a couple of adjustments to prevent this. This MAY have

been why the IF amplifier cathode resistor (300 ohms in the schematic) was found

to be 990 ohms originally. Perhaps this was a production change. I

left the 300 ohm resistor in place. The radio performs well, and has very good tone on the broadcast band.

The volume control was really not in good shape. It was the type that

did not respond well to cleaning (a metal ring compressed against the resistance

element - I have found that attempting to clean these types will destroy the

resistance element). It worked OK, but during rotation the set would break into

oscillation (likely due to loss of contact on the center element). I did

not replace it in an attempt to maintain originality. This set will likely

be a SHELF QUEEN rather than a daily driver.

Restoration Results

|

Chassis Before Restoration |

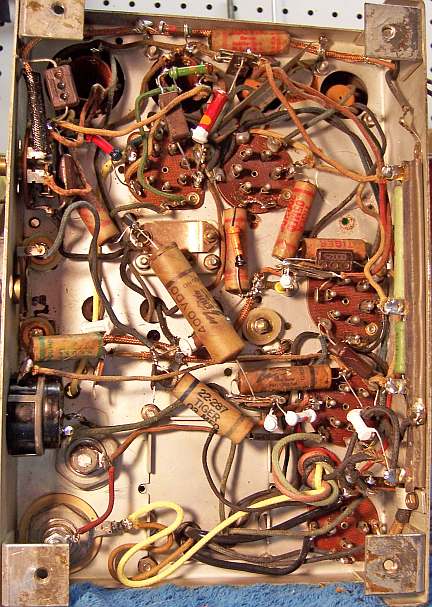

Chassis After Restoration |

|

|