ERLA 271-A Restoration

|

The Erla 271-A Tombstone, circa 1931 is a 7-tube TRF circuit

radio, made

by Electrical Research Labs, Chicago. The unique feature of this

radio is an electric clock mounted in the center of the speaker.

The radio had seen some servicing in the past, but most of the original parts were still in place. I decided to try

to maintain the original above and below chassis appearance and to reverse

all previous repairs to the extent

possible. The schematic for this radio can be found on-line at Nostalgia

Air. |

My

antique radio restoration logs

Condition As Found

This radio was purchased on eBay. The cabinet was in

good original condition, as were the

knobs and grille cloth - just the usual wear, dings and scratches. The

radio was sold as working, but with the clock not working. There was no evidence that the radio had been

restored by a collector - only normal radio shop servicing long in the past. Even the line cord was original, but in

poor shape. I always avoid knowingly purchasing a radio that has been

restored by a collector, as many take shortcuts such as removing the original capacitors and filters.

There

was unfortunately some damage in shipment. The radio had been packed in

the typical Chinese shipping carton. These are not very sturdy. The

only padding was a 1" layer of Styrofoam all around, and this is a VERY

heavy radio. During shipment the speaker baffle board had separated from the

cabinet, allowing the speaker with baffle attached and the clock to rattle

around in the cabinet! Fortunately, the clock did not appear to have been

damaged. But there was damage to the fragile speaker cone, and cosmetic

damage to the output transformer (it still worked, although one secondary lead

was broken and insulation scuffed, exposing some of the secondary winding). The baffle to cabinet attachment was simply a few small

screws. It is very likely that this damage would have occurred

regardless of how well the radio was packed, unless the speaker had been removed

for shipment.

When tested, the radio actually did work as stated, so all major

parts should be OK.

Previous Repairs

-

All the tubes had been replaced, probably more than

once! All tubes were

shouldered or ST type. The radio originally would have been fitted

with globe type tubes (the sockets were marked 245, 280, 227 etc.)

-

One paper capacitor had been replaced (the original would

likely have been a Dubilier CUB type, one of which was still in

place). Most of the bypass capacitors were in metal cans and original.

-

The filter capacitors had been replaced - the originals were

Merchon copper screw-based units with the plus terminal at the top rather

than under the chassis. The original female mogul screw bases were still

present.

-

All the original resistors were still in place.

-

The dual tandem volume control with switch had been replaced

by a single control, which was now bad.

-

The AC plug had likely been replaced.

-

One RF amplifier tube grid cap had been replaced by a bent

piece of metal.

-

There were some taped repairs to the AC cord inside the

clock, which had likely shorted out sometime in the past (where the cord

passes through a hole in the metal back of the clock, which has no grommet).

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise. Since

the radio actually worked, no major components were defective (RF coils, chokes,

transformers, RFCs,

etc.)

-

The line voltage selector toggle switch on the back was bad (it measured a high resistance) - dirty and/or oxidized contacts

were likely.

-

The volume control (not original) was open.

-

One chassis bolt was missing.

-

Most screws holding the speaker baffle board were missing.

-

The speaker field was OK.

-

The speaker cone was torn in several places due to shipping damage.

-

The output transformer was OK (some cosmetic damage in shipping).

-

The audio input transformer was OK.

-

The filter choke was OK (fortunately - it has a very unique construction)

-

The power transformer was OK.

-

All tubes were good, although globe types would be correct for this

radio.

-

The power cord was original (black twisted cloth covered) but in poor

condition. The plug had been replaced.

-

Two original dogbone resistors were out of tolerance. The 45 tube filament

shunt resistor was broken.

-

Almost all wiring in the radio was cloth covered and was OK.

-

The clock was stated as not working. When started, it would actually

run for a few seconds. I suspected that it simply needed cleaning and

lubrication.

-

Whatever retained the pilot lamp socket was now missing.

Repairs

At this point I made BEFORE photos of the chassis bottom. I use these photos to ensure that replacement parts and

wiring are placed as close as possible to their original positions. Some

radios are subject to problems (such as oscillation) if wiring is re-routed or

lead dress is not the same as the original..

All tubes and tube shields were removed. The tuning capacitor and dial

assembly was removed for cleaning and access to other parts on

top. All non-original parts were then removed.

The top and sides of the chassis was cleaned with GoJo hand cleaner and 00 steel

wool. Since this process may leave small steel wool fragments that can cause

problems later, I follow up with a thorough vacuuming and go over everything

with a small magnet and masking tape to pick up any stray fragments.

The power cord was replaced with old-style black twisted lamp cord available

from Grand Brass Lamp. It is not a

real close match to the original, but is all I could find! It is at least

black and twisted, but is somewhat thinner than the original. The covering

is synthetic material, vs. cotton on the original. The cord set came with

an old style molded plug, which was retained (the plug that came with the radio

was not original). The socket for the clock was re-used.

A new #41 pilot lamp bulb was fitted. A rubber grommet was used to

mount the lamp socket onto its bracket.

Volume Control

The volume control on this radio originally was a ganged wire wound control

with switch One section was 5K ohms and controlled the screen grid

voltage of the three 224 RF amplifier tubes, and thus the gain. The other

section was 10K ohms and was an antenna shunt. I contacted Mark Oppat

about a replacement part. He said that they were not available (he can

normally supply almost any vintage replacement potentiometer). There was a

work around available but the radio would have to be modified and rewired to use

a single control. I wanted to avoid that if possible.

The original control had been

replaced by a single 10K ohm wire wound control with attached switch, controlling

only the screen grid voltage to all three RF amplifier tubes. This replacement was now defective. There

was no continuity between the low end of the wire wound element and the rheostat

terminal, thus providing only limited control of volume. This control was repaired by:

- Inserting a paper thin sliver of brass about 1/8"x3/8" (material

normally

used for model railroad construction) between the

resistance wire and the outer insulation on the low end of the control. The brass was

first sanded until bright, and then cleaned.

- Drilling a small hole adjacent to the low end terminal through the insulation.

- Attaching a thin wire to the terminal, threading it through the drilled hole, and

soldering it to the top of the brass insert (now in contact with the low end

of the resistance wire)

The repair was successful - the control measured 10K ohms and the resistance

varied smoothly as the control was rotated.

Clock

The Hammond clock used in this radio is not self-starting. One must

push in on a rear knob and spin counterclockwise to start it, and the speed of

the spin is critical! If power fails, the clock must be restarted!

But one must first remove the clock from the radio in order to restart it or set

it - the controls on the back are not accessible from the rear. There is a rotating indicator disc on the front of the dial, which indicates

that the clock is running. The clock was sold as not working. I had hoped

that the seller and other eBay bidders simply did not know that the clock must be manually

started! When tested, the magnet coil was OK. The clock would runs

for a few seconds after starting and then quit. I suspected that the

mechanism needed cleaning and lubrication. In some cases the motor capsule

must be rebuilt - a task for an experienced clock repair shop, since the

bushings inside the capsule are likely worn and have to be replaced.!

The clock was completely disassembled, and all parts cleaned in lacquer

thinner. To keep track of all the various parts, I took photos as the

mechanism was disassembled, kept the parts in order through the cleaning

process, and made careful notes. Below are the first few steps of the

movement disassembly.

There did not appear to be any pivot holes with excess wear that would

prevent the gear train from working correctly - lucky! If heavily worn,

and the pivot holes oblong in shape or much larger than the pivots, the gears may jam.

The

movement was very dirty and caked with hardened and oxidized grease or oil. The pivot holes in the plates were cleaned with wooden toothpicks and/or

pipe cleaner soaked in lacquer thinner. The movement was then reassembled

and the pivots lubricated with proper synthetic clock oil. The wiring

inside the clock case was taped and a splice found that was not even soldered! This was

repaired using shrink tubing and electrical tape, thus retaining the original clock

cord and plug. Once assembled, the clock started and continued to run and

to keep time. I did not mess with the motor capsule - just some lubrication

on the front shaft and bushing.

Resistors and Capacitors

The 45 tube filament shunt resistor (20 ohms, center tapped) had broken near

the tap terminal. I was not able to repair it. It was replaced by a

50 ohm wire wound resistor of similar size and appearance - but this replacement

resistor did not have a center tap.

I was able to remove the tap terminal from the original resistor and attach it to the

replacement. I did not manage to get the tap attached to the exact center

of the replacement - the two halves measured 15 and 17 ohms. Hopefully the hum

will not be excessive due to this imbalance. Two dogbone type resistors

were out of tolerance, but thankfully most others were very close to correct. One

large 10K ohm 2 watt dogbone resistor was replaced by a similar type resistor which was

slightly larger. The replacement was originally a different (lower) value but had

drifted to the correct value over time! It was repainted to match the

original resistor using hobby paint. The 45 output tube cathode (filament)

bias resistor (1500 ohms) was about 30% high and I did not have a suitable

replacement in stock. So I cheated! A shunt resistor was hidden

inside the restuffed cathode bypass capacitor (1mfd) so that the resistor now

measured the correct value.

All of the bypass capacitors in the set were metal cased units with 1 to 3

capacitors inside. The capacitors were removed from the chassis and contents

removed, retaining the original terminal strip and insulation. Only the

capacitors and potting compound were removed, taking care not to damage the

insulation and terminal board. The cases and insulation

were then soaked in paint thinner and cleaned with old toothbrushes. Suitable new film

capacitors were placed inside, connected to the original terminal board, and the

capacitor then filled with melted rosin/wax salvaged from servicing 1924 RCA

Superheterodyne catacombs. This wax melts at a low temperature and will

not damage components. The rosin/wax keeps the replacement capacitors and

the terminal strip in

place. In one case I noticed that the capacitor had one 0.1mfd and two

0.25mfd 200 volt capacitors, but the 0.25mfd units were used in parallel.

This capacitor was restuffed with one 0.47mfd 630 volt capacitor rather than two

0.22mfd units. One original metal cased capacitor had lost its paper

label. I scanned the an existing label and attached it to the capacitor

missing a label.

There were also two tubular capacitors used. One was the second detector

plate capacitor (0.004mfd) and the other was the audio coupling capacitor

(.01mfd). The audio coupling capacitor was not original, and had been

replaced by a 500pf paper capacitor! That could not have worked very well

- frequency response would have been limited and gain reduced. The other

capacitor looked to be the original Dubilier CUB type capacitor. I thus

assumed that the audio coupling capacitor should also be a Dubilier CUB type. I

collect branded dud capacitors (Zenith, Philco, RCA/GE, and Dubiler Cub) for the

purpose of "reversing" previous repairs. I had a Dubilier CUB

capacitor in stock, but it was not a 0.01mfd. I restuffed it with a

0.01mfd/630 volt film capacitor, and installed it in the radio so that the value

marking was not visible - only the Cub label. Here is my method of restuffing

Dubilier Cub capacitors, which are quite unique in appearance. The

second detector plate bypass capacitor was original. It was hoped that it

was not leaky and thus could be retained (some low value capacitors test out

OK). But alas, it showed a leakage resistance of only 500K ohms on my Tel-Ohmike

TO-4 capacitor tester, and I did not feel I could trust it. It was

restuffed using a 0.0047mfd/630 volt unit. In this case there was no

cardboard tube - the label was attached directly to the paper/foil roll.

So I slit the label and foil with a razor blade and removed the label. A

found a suitable cardboard tube in my dud capacitor stock, restuffed it,

attached the original label, and then attached the original metal end

caps. The slit in the label was positioned so as not to be visible when

the capacitor was reinstalled.

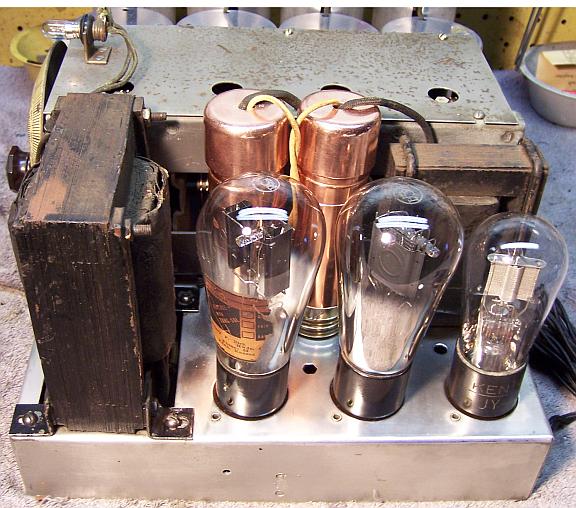

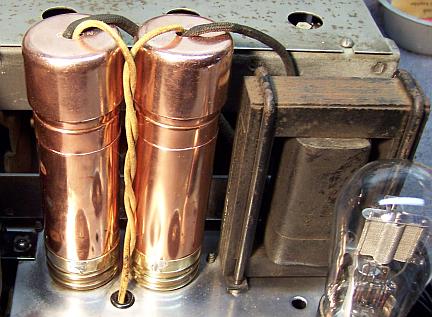

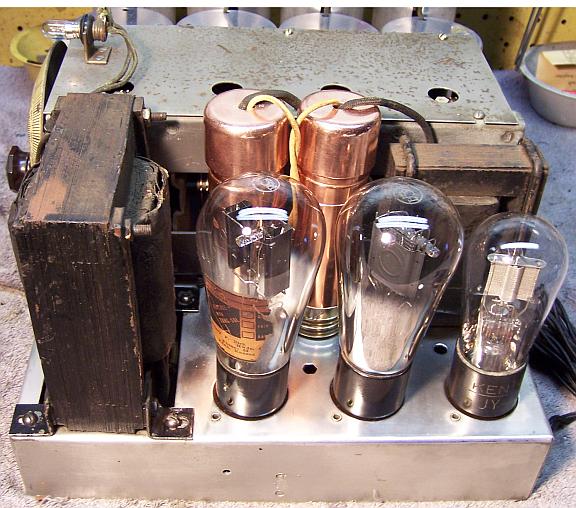

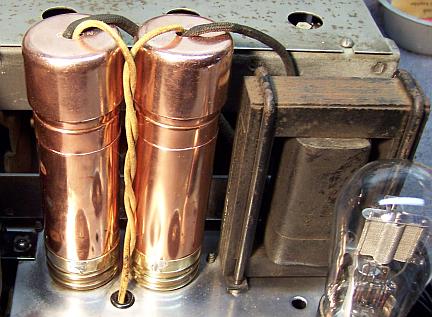

Mershon Filter Capacitors

The original Mershon screw based filter capacitors had been replaced in prior

servicing. These units are quite unique: they are made of copper and have a large

mogul base that screws into a brass socket riveted to the chassis.

This provides the

negative terminal. The positive terminal is on the TOP of the capacitor,

and there is a copper cap that protects prying fingers from the full B+ voltage

present! Fortunately,

the sockets were still in place. I was fortunate to be able to purchase

two original capacitors from the good folks on AntiqueRadios.com

classifieds. Unfortunately, these did not have the original covers,

since the capacitors had been clamp mounted under the chassis of the donor radio

(the owner elected not to restuff them since they were not visible). But I found that

normal plumbing hardware (1.25" pipe caps) fit well and were at least

similar to the originals. I have seen photos of pipe caps that do look

like the originals - I will keep my eye out for them when visiting Lowe's etc.

or large hardware stores. The capacitors were originally 8mfd. They

were restuffed using 10mfd/450 volt capacitors. To restuff them, the capacitors

were first chucked in my small Unimat lathe and their cases deeply scored about 1" down from

the top (terminal end). A mark was scratched on the case across the

planned cut in order to maintain the original orientation and thus a snug fit. The

cut was then completed using a hobby razor

saw and cleaned up using an Exacto knife. This left only a thin line on

the case - hardly visible. The original contents (insulator and liquid

electrolyte) were then removed. The original

positive element inside was removed and the stud was cut short and then drilled and

tapped to accept a ground lug and 8-32 screw. The

capacitor case was then cleaned and polished using Brasso. The positive

lead of the replacement 10mfd/450 volt capacitor was attached to the ground lug.

The negative lead of the

replacement capacitor was extended and soldered to the inside lower part of the

case, since this part mates with the screw base on the chassis and provides the

negative connection.

The two halves

of the copper case were then rejoined using a piece of a 1" PVC plumbing

coupling wrapped in

masking tape (to ensure a snug fit inside the case) and attached to both halves of the case using epoxy.

|

|

| Finished capacitor with a 1.25" pipe cap to replace the missing top cover. |

Finished capacitors in place in the radio.

I later found out that the originals had rubber grommets installed! |

Tubes

The radio was re-fitted with globe type tubes for the 280, 245, and 227

driver tube - these tubes are visible. The remainder of the tubes are

inside shields, and not visible. The original tubes were left in place,

since they were good.

Cabinet

The cabinet only needed a good vacuuming inside and then cleaning on the

outside with GoJo and 00 steel wool. The speaker baffle board was

reattached securely with additional screws (holes were extant). The top of

the cabinet was loose from one side - the glue joint had failed, perhaps due to

shipping. The crack was glued and clamped.

Testing and Alignment

Once the radio chassis was reassembled and the tubes installed, power was brought up

slowly using a variac. AC power consumption was monitored using a watt meter, and a

DVM monitored the B+. The radio powered up and worked immediately. The radio was then

aligned. The radio performs well, is quite sensitive and has very good tone. The

rebuilt volume controls works smoothly. There is minimal hum, so that the

45 tube filament shunt resistor center tap was close enough! The

patched up speaker cone seems to work OK - no rattles and reasonable tone

quality.

Restoration Results

Chassis Bottom Before and After Restoration