General Electric Model L-50 Restoration

|

The GE Model L-50 with repwood cabinet (which uses the same chassis as the RCA model R-22) is a

5-tube AC (or DC) Superhet

circuit radio that

receives the broadcast band and one short wave band. The radio had been serviced in the past,

but most

of the original

parts were still in place. I

decided to try to reverse all prior servicing and to restore the original chassis appearance if

possible.

The schematic and a parts list for the GE L-50 can be found on-line on Nostalgia

Air.

|

My

antique radio restoration logs

Overview

The radio was purchased at the 2014 CC-AWA Convention and swap meet

in Charlotte, NC, and was sold as not working. The circuit it uses is quite unusual

for several reasons:

-

The radio operates on either AC or DC, but a switch on the

back selects which type of power! In AC mode it uses a voltage doubler

circuit, and the performance should be significantly better than in DC mode. The

power supply, while quite simple, is also quite clever. In DC mode, it

blocks power to the filter caps and radio if the plug is reversed. It

should also even work on AC power in DC mode, but at a reduced level of

performance, since only half-wave rectification is used.

-

It has a tuned RF amplifier stage, but no IF amplifier

stage. It compensates for this by using an type 77 anode bend

detector stage rather than a simple diode second detector. This type

of detector provides the audio gain needed without having to have an audio

amplifier stage. But distortion is higher, and there is no Automatic Volume

Control (AVC) function provided.

-

It receives the broadcast band and a "police" or

short wave band of only 2.4-2.5mHz. For this band, the RF amplifier

and first detector stages are untuned and essentially broadband. Thus

there would be severe problems with images.

-

The band switch is a small wooden dowel protruding from the

front of the cabinet near the tuning knob. There is no knob - just the

protruding dowel. Almost every GE L-50 I have seen is missing this part,

since it is very fragile. The dowel must be turned 90 degrees to switch

bands. If turned too far the dowel can be damaged and the radio would no

longer work correctly. I was excited to find a radio with this part and its

associated mechanism still intact. Most recent eBay and Radio Attic

sales of this model, as well as some photos at Radio Museum, are missing this part. If

removed completely from the radio, the radio will work correctly on the

broadcast band. The "sort of" short wave band is useless

anyway.

-

I had previously purchased another example of this radio on eBay, but

it was destroyed in shipping due to terrible packing! It was not

restorable, and an insurance claim was filed. That radio was also

missing the band switch shaft and mechanism. But it did have the

original filter capacitors in place. Unfortunately, the Post Office

wanted it brought in for scrapping! I would have loved to have the

chassis for a parts set!

Servicing this radio is very difficult due to the compact chassis, high

parts count, and relatively large components used in RCA/GE radios of this

vintage. The radio appeared to have been built in layers, and some parts have to

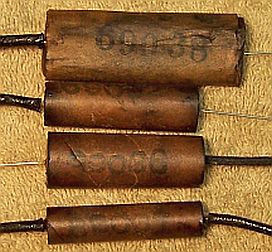

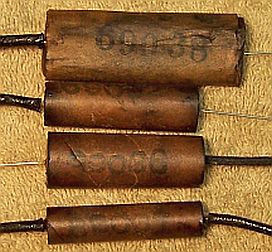

be removed in order to gain access for servicing. All the resistors used were old-style "dog bone"

types. A large wire wound resistor was also used which functioned as the

filament dropping resistor. Adding to the complexity, the original filter

capacitors had been replaced by a twist lock type capacitor mounted on ceramic

stand-offs on top of the chassis. The filter protruded from the back of

the radio and would be "hot" to AC even if the radio was switched off.

The RCA/GE parts placement

diagram provided in Riders did not match my chassis. What were originally

individual paper capacitors had been replaced by two RCA/GE capacitors containing

multiple units - likely an undocumented production change to simplify assembly.

One such capacitor contained two capacitors (C1 and C25) and had three

leads. Another contained three capacitors (C12, C13 and C27) and had four

leads. Part C24 was not found, and likely eliminated in a production change or when

the filters had been replaced. The

IF transformer and second detector plate choke are very fragile with exposed,

unprotected wire leads which are easily damaged.

Previous Servicing

I always attempt to avoid purchasing radios that have been

"restored" by collectors or flippers, and am looking for either all

original examples or those which have been "lightly serviced" in the

distant past by radio service shops, rather than peppered with new film

capacitors. This radio had received prior

servicing, but most of the original

parts were still in place. It was not clear who might have done this repair

- it appeared too extensive and complex for a service shop repair.

- The band switch shaft notches had been enlarged and modified. A

C-clip had been added to the outside end.

- The two cardboard cased filter capacitors had been replaced. A four

section twist lock capacitor had been mounted on the chassis on ceramic

stand-off spacers (the chassis is NOT at B- potential). Two additional

tubular electrolytics had been mounted under the chassis. The

replacement capacitor had not been wired per the schematic, and its

capacitance was much larger than the original capacitors. I have

seen other examples of this radio with non-original but similar/compatible

cardboard case replacement filter capacitors. So replacements must

have been available early in the life of this model.

- The AC/DC toggle switch had been removed.

- All of the original dogbone resistors were still in place.

- All of the original paper capacitors were still in place, although I never

found part C24. C24 (0.1mfd) originally would have essentially bypassed the

output filter capacitor and thus prevent any coupling between stages.

It may have been removed when the filters were replaced, or may have been an

RCA/GE production change.

- The original cloth covered power cord and plug were still in place and

safe to use.

- The original antenna and ground leads had been removed. A new hank

of wire had been added, but only connected to one of the antenna coil

terminals (and thus would not have worked very well).

- Only two of the tubes were branded RCA-Cunningham, so the remainder were

replacements. A 6D6 replaced the type 78 tube.

- The tube shields had been removed - they are very difficult to re-install

in the cramped chassis, so they likely would have been discarded after tube

servicing.

- Some new wiring had been added due to changes needed for filter capacitor

replacement.

Chassis Before Restoration - Back View - Filter Caps

Replaced

Tube Shields Missing - AC/DC Switch Removed

|

|

Cleaning

The chassis was very dusty, but not rusty. All tubes and tube

shields were removed. The dust was blown off, top and bottom, using an air

compressor. After removal of the volume control, speaker, and tuning capacitor the top of the

chassis was cleaned using using old tooth brushes and a vacuum to remove dust

from the crevices. Parts of the chassis were then cleaned with GoJo (white) hand

cleaner and 00 steel wool. All of the paper capacitors had been previously

removed before removal of the speaker, since some of its connections otherwise

were not accessible. Since steel wool may leave behind small metal fragment, I

went over the chassis with small magnets just in case. Some of the gunk on

the chassis was very difficult to remove.

The tuning capacitor was partially disassembled for

cleaning. All the trimmer screws, washers, and mica sheets were first

removed, as was the band switching contact assemblies and brass stator grounding

fingers. Prior to removing

the trimmer screws, the current position of the trimmers were documented so they

could be returned to their approximate original positions:

-

The original position of the trimmer screws on the clock was

noted.

-

The screw was then tightened fully, noting the number of 1/2

turns (and fractions) to tight.

-

The screw was then removed along with the washer and mica

insulator.

-

After cleaning, the process was reversed. The mica strip,

washer, and screw were re-installed.

-

The screw was again fully tightened.

-

The screw was then loosened the correct number of 1/2 turns

The tuning capacitor was cleaned in my old Heathkit ultrasonic

cleaner using dilute ammonia. Multiple cleanings in various positions were

needed, since the capacitor would not fit in the tray. After cleaning, I

used soap, water and old toothbrushes to clean up the capacitor. The

capacitor was then towel dried and then dried using a heat gun. The front ball

bearings were lubricated using automotive distributor cam lubricant.

Survey

Before starting

restoration I made photos of the chassis bottom for reference. I then annotated

a copy of the schematic, as well as the chassis photograph, with reference part

numbers (R1, R2, C1, C2, L1 etc.).

-

The band switch shaft was broken, but all its parts were

present.

-

The speaker field coil was OK.

-

The output transformer and speaker cone were OK.

-

The filter choke was OK.

-

All RF coils and the IF transformer were OK.

-

The power switch was originally inoperative. After a

shot or General Cement Big Bath spray cleaner and repeated cycling, it then

worked.

-

The volume control was intermittent and indicated open

circuit at certain points.

-

Two small resistors were out of tolerance by more than 20%

(some as high as 50%). One was a 1/2 watt dogbone, and one was a 1/4

watt dogbone.

-

The wire wound power resistor R9 was OK.

-

The power cord was original and safe to use.

-

One chassis bolt and washer were missing.

-

The 25Z5 tube was dead on one side, likely due to a B+

short. The 6A7 and 77 tubes tested slightly weak. The 43 tested good.

Restoration Strategy

I assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original components if possible). I

do not replace mica capacitors, but may test them in place if possible (usually

this requires disconnecting one lead of the capacitor).

Since almost all of the original parts were still in place I decided to try

to maintain the

original chassis appearance to the extent possible. Normally I would

rebuild all original wax-paper capacitors as well as the filter, block, and can capacitors in

their original cases (restuff them). In this case, the original cardboard

cased filter capacitors had been removed. So I would have to try to

reproduce them (I did have photos of the originals used from my damaged example

and other on-line sources).

When I replace a component, I

always remove the original part completely from a terminal. Other good components connected at the terminal are protected from heat using old medical

clamps (hemostats). Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

The RCA/GE terminals used in this vintage radio are quite

fragile and must be handled with care. Most consist of three legs with a gap

between the two outer and center leg. When assembled, the various wire

leads and components are placed in the gap and then the three legs are crimped

closed and soldered. In order to service any wires or components, I first remove

as much solder as possible using a pump-type solder sucker. I then VERY

CAREFULLY tease the three legs apart using an Exacto knife and remove more

solder, thus freeing up any parts or wires. The legs must be moved only the

minimum amount. If moved too much or too often, one or more of the legs will

break off in a heartbeat!

Repairs

Band Switch

Until I bought this radio, I had no idea what the original band

switch mechanism looked like. And most photos I have found on-line were missing

this part. This radio's band switch shaft and mechanism were intact, but

the shaft was broken. The original shaft had been modified for some reason. The notches that

operate the switching mechanism had been enlarged and displaced horizontally and

angularly on the shaft. This greatly weakened the shaft and it had broken. There

was very little remaining wood left for gluing it back together. So I

decided to attempt to reproduce it. The required diameter was slightly smaller

than 1/4", so a standard 1/4" hardwood dowel was too large. And

the next size down was too small. So I started out with a 6" piece of

1/4" poplar dowel, chucked it in my small Unimat lathe, and used fine

sandpaper to reduce the diameter until it would fit in the holes in the tuning

capacitor.

The required locations for the notches were then marked. A fine

razor saw was used to cut the start and end of each notch. The depth of the cut

was about 1/3 of the diameter of the dowel. The material between the cuts was then removed with an Exacto knife with a new, sharp #11 blade. Several

different depth adjustments were needed until the switch contacts worked

correctly in both positions. I then cut some shallow notches on the shaft for

the device that limits rotation to 90 degrees. These

notches must be cut in the correct position so that when the limiter cam is

installed, the switch operating notches are in the correct positions! Once

correct operation of the switch was verified in both positions, the limiter cam

was then closed up around the shaft. At least one collector installed a small

knob on the shaft in his radio to make turning the shaft easier. But this

invites disaster! If the shaft of forced one way or the other, the limiter

cam will break free and the switch operating notches will now be out of

position.

Here is the tuning capacitor with the replacement band switch

shaft installed, along with the broken original shaft. The completed shaft was

painted gloss black before installation.

Volume Control and Switch

After marking its position, the back cover and switch were

removed by prying up the retaining tabs on the cover. The wire-wound resistance element was then cleaned using lacquer

thinner and Q-tips. The element itself was OK. But I measured a high

and intermittent resistance between the rotating element and the terminal

lug. The brass sliding contact and pressure spring were removed. You

must make careful note of the contact's position relative to the rotating

member, and make sure to keep control of the spring during removal or

replacement! The C-clip retaining the shaft was then removed (with difficulty).

The problem appeared to be dried grease between the rotating member and the

fixed contact. I cleaned both parts with lacquer thinner and reassembled

the control. I did NOT replace the grease. Once reassembled, the

control worked perfectly.

While the switch was removed, I flooded it with General Cement

Big Bath spray cleaner and operated it repeatedly. It then seemed to work

OK. The back cover and switch were then reinstalled and the retaining tabs

bent back in place to hold the back. It is very important to mark the position

of the cover prior to removal, since the rotating member has hard stops on both

ends. If not done correctly, the switch may not open or close at the

correct points in the rotation.

AC/DC Toggle Switch

The original AC/DC toggle switch on the rear chassis had been

removed. I found a suitable switch (Single Pole, Double Throw) in my junk box

that could be used, although it was not a bat-handle type like the original. All

the wiring to this switch had been removed. It was restored using the

supplied RCA parts connection diagram. I did not test the radio in DC

mode. but I did want to restore the set to its original factory wiring if

possible.

Wax/Paper Tubular Capacitors

All except one of the original paper-wax capacitors were cardboard tubes sealed on both

ends with tar. After each one was removed from the radio, the lead lengths and

type and

any use of insulating sleeving were noted so that lead dress and appearance could be

maintained. Restuffing these early RCA/GE capacitors is quite messy. Here

is my process for the capacitors with cardboard tubes:

- The capacitor is held and rotated using one of its leads using needle

nosed pliers while the tube is heated using a heat gun to soften the

tar.

- The tube is held using paper towels while the contents are pulled out one

end. In most cases, both leads as well as most of the tar came out as

a unit. In some cases the leads pulled out and the contents had to be

pushed out using a small screwdriver.

- Any remaining tar was removed from inside the cardboard tube, and the

outside of the tube cleaned using lacquer thinner.

- If the required lead length on either end exceeded the length of the

replacement axial film capacitor, suitable bare buss wire was attached to

the replacement capacitor close to its body, so that the splice would be

inside the cardboard tube after restuffing. Some of the capacitors

used insulated wire of varying colors rather than bare leads.

- The replacement capacitor was then wrapped with strips of paper towel to

center the capacitor in the cardboard tube and prevent it from falling out.

- The ends of the tube were then sealed using rosin salvaged from servicing

RCA Radiola Superheterodyne catacombs.

- One of the capacitors (the top one in the left photo below) looked like a

block of tar wrapped in a thin paper wrapper. Here

is my restuffing process for this type of capacitor.

Two capacitors contained multiple capacitors.

One such capacitor (RCA part 69071) contained two capacitors (C1 and C25) and had three

leads. Another (RCA part 69070) contained three capacitors (C12, C13 and C27) and had four

leads. The leads for these capacitors were insulated hookup wire rather than

solid buss wire. The cases were normal tubular or oval cardboard, and the ends

were sealed with tar. If was not obvious what these capacitors were until they

were removed from the radio, since their use was not documented on the RCA

connection diagram. As their leads were disconnected, careful notes were

taken. When compared to the schematic, they were eventually identified. This was

quite difficult, and I started by first removing and identifying all the single

paper capacitors then figuring out what was missing. A missing C24 made this

harder. The restuffing process for these was the same as with single

capacitors, except that interconnected axial tubular film capacitors and hookup

wire was used.

Restuffed Single Paper Caps

|

Restuffed Multiple Paper Caps

|

|

|

Filter Capacitors

The original filter capacitors had been removed.

Fortunately I had photos of the original capacitors I took from another example

of this radio which was destroyed in shipping. There were originally two cardboard cased capacitor used,

each containing either two or three electrolytic capacitors. The schematic

in Riders shows the internal connections and wire colors for these

capacitors. I was able to reproduce suitable cases for them made from thin

cardboard similar to the kind used for writing tablet backs. Their measurements

were obvious from photos and from the location of mounting and wire lead holes

on the chassis. The left capacitor (viewing from the radio back) originally contained two 8mfd

capacitors (C22 and C23). The reproduction case was restuffed with two 10mfd/450 volt

electrolytics. The right capacitor originally contained a 4mfd, 8mfd, and

10mfd (low voltage) capacitor. C21, a single separate 8mfd capacitor had been

replaced by a modern unit. I had no idea what the original capacitor looked like

or its size. According to the RCA connection diagram, it was originally mounted

somewhere under the chassis.

I decided to cheat a bit and install C21 inside the case with

C22 and C23. Again, I used a 10mfd/450 volt electrolytic. In

reality, both C21 and C22 could have been rated at 160 volts, and probably were

in the original radio. These capacitors form each side of the voltage

doubler. In order to accommodate C21 I added a third lead to the left

filter capacitor: a green lead which was routed to pin 4 (cathode) of the 25Z5

tube.

I also decided to include the missing C24 (0.1mfd) in the right,

smaller filter case, just in case it might be needed. Recall that it was

not found under the chassis, and I did not know if it had been removed during

the filter capacitor replacement or a production change. A 0.1mfd/630 volt film

capacitor was connected from the + lead of C28 (the B+ output filter) to B- (C18

and C26 negative). For C26 (4mfd) I used a 4.7mfd/450 volt electrolytic. For C28

I used 10mfd/450 volts. For C18 (10mfd) I used a 10mfd/50 volt electrolytic.

The length of each lead wire was calculated by running some

trial routings from the chassis holes to where the lead connects. Extra length

was added for connections to the new capacitors inside the case. The new

leads were connected to the new filter capacitors using the RCA diagram.

Insulating spaghetti tubing and shrink tubing was used to prevent shorts. The

groups of capacitors were then wrapped with strips of paper towels to stabilize

the assembly in the cardboard case. I then added melted rosin from the open

bottom of each case to stabilize the assembly. The exiting lead wires were first

wrapped with tape in order to center them and allow passage through the chassis

holes. I did not include a bottom cover on the fabricated filter capacitor

boxes. The bottoms fit tightly against the chassis.

The case color was a problem. I did not want to just leave

the bare cardboard filters as they were. Ideally they would be painted the same

color as the originals (I had a photo of the originals). I experimented with

various paints, toners, and shellac without success. I finally decided to simply

enlarge the photo of the originals, print the photo, cut paper covers and apply

to the outside of the cardboard cases using wood glue. It seemed to work

OK. The result was not perfect, but better than any alternative that I

could think of.

Here are comparison photos of original capacitors and my

reproductions.

Original Filters

|

Reproductions

|

|

|

Small Resistors

Two small resistors were out of tolerance by more than 20%.

One was a 20K 1/2 watt dogbone resistor (R3) and one was a 1 megohm 1/4 watt

dogbone (R2). I

collect NOS as well as used dogbone resistors just for this purpose, and buy all

I can find on eBay and at swap meets. I did not have replacements

available that were in tolerance. In this case I attempt to find a

replacement that is the correct size and has the correct measured value (within

20% tolerance) but not the correct value markings! I then repaint the resistor

with the value required using hobby enamel paint. The 20K 1/2 watt resistor

(R3) required one long

lead, which I did not have in stock. So I was forced to splice on a piece

of buss wire. The splice was covered using spaghetti tubing over the entire

lead..

Tubes

The bad 25Z5 tube was replaced. The 6D6 was replaced by a

correct type 78 (the 6D6 is an acceptable replacement). The remainder of the

tubes were left in place.

Other Repairs

Suitable tube shields (three) were installed.

The non-original antenna lead was cut in half and re-used, but connected and

installed per the connection diagram.

Testing and Alignment

Once the radio had been reassembled,

the radio was powered up slowly using a fused Variac. This allows the new filter capacitors to reform. A DVM monitored the B+ voltage. Surprisingly,

the set came alive and worked, even with all the work done under the chassis!

The set was then aligned per the RCA instructions in Riders - no surprises. The

set worked on both bands, and was very sensitive. Volume control action was

smooth, but since the set did not have AVC, it must be changed while tuning. The

so called short wave band picked up quite a few stations, but only the in center

of the tuning range (the specs say the range is 2.4 to 2.5mHz). The radio was

NOT tested on DC.

Tuning this radio is very difficult since there is no reduction drive - the

small tuning knobs turns the tuning capacitor directly.

Cabinet

One side of the cabinet had started to pull away. It was reglued and

clamped. The cabinet was vacuumed inside and out. I found out during the

clean-up after gluing that the finish would be removed with even small amounts

of water! Fortunately, only the edge of one side was affected. A test in a small

area with GoJo,

my usual cabinet cleaning method, was performed and also found to damage the

finish. So the cabinet was left as is.

Restoration Results

Chassis Bottom Before

|

Chassis Bottom After

|

|

|

Rear Chassis After Restoration - Repro/Restuffed

Filter Caps

Tube Shields and AC/DC Switch Replaced

|

|

|