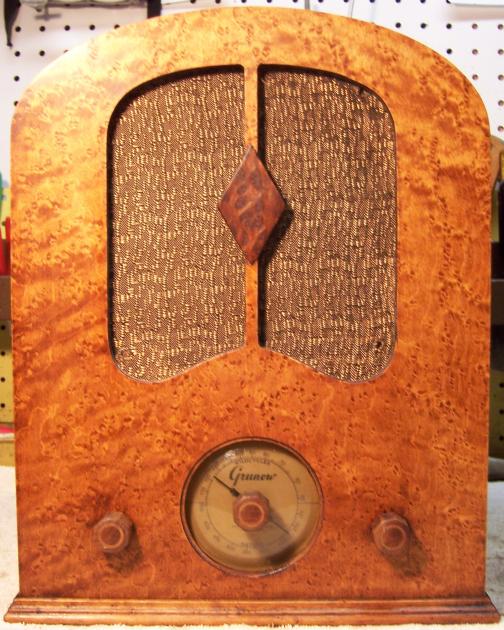

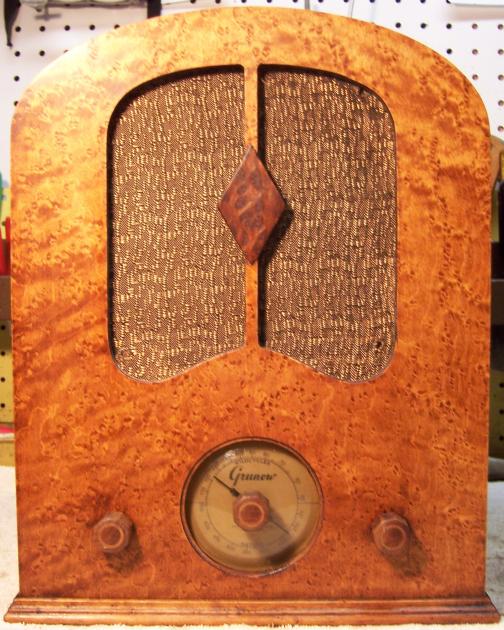

Grunow 460 Small Cathedral Restoration

|

The Grunow 460 is a small 4-tube non-AVC superhet circuit cathedral

style radio with a distinctive curly maple veneer cabinet. Grunow

was a trade name of the General Household Utilities Co. The 460 only receives the broadcast band and requires an

external antenna (and ground). The radio had seen minimal servicing in the past and most original

parts were still in place. This being the case, I

decided to try to reverse any previous servicing and retain the original top and bottom chassis appearance if

possible. The radio was purchased on eBay. The seller stated that it

"needs work" - that was a bit of an understatement!

The schematic and a partial parts list for the radio can be found on Nostalgia

Air. Any part number references in the text below reference that

schematic.

|

My

antique radio restoration logs

Previous Servicing

-

The original filter capacitor bank (a cardboard cased unit

mounted under the chassis) had been removed and several modern capacitors

tacked in. The original was a dual 8mfd unit at 350 volts. The

replacement were four 4.7mfd @ 450 volts (two 4.7mfd in parallel on each side of the

speaker field).

-

All resistors and paper-wax capacitors were original

-

The line cord and plug were original and even usable with

repairs.

-

Three of the tubes were branded RCA or RCA/Cunningham and

may have been original. The 6A7 was a replacement.

Survey

This radios is difficult to service with limited access to

several parts due to the rather small chassis and the tuning capacitor being

mounted under the chassis. My usual restoration procedure is to make a complete

survey of the condition of all components and repair all items before the radio

is tested. It may not be possible to test high value resistors because of

leaky capacitors. In this case, one end of the resistor must be

disconnected or leaky capacitors disconnected. The eBay seller made no statement about the electrical condition

of the radio. Like in Zenith radio schematics, all parts having the same

part number use the same call out in the schematic. So there are multiple occurrences

of R7, C11, and C14 on the schematic. Before doing the survey I first make

these occurrences unique by adding a suffix letter (A, B, C etc.)

-

The power transformer was defective! The primary winding was

open, and the high voltage secondary measured a very low and asymmetrical

resistances across the center tap: 8.3 ohms on one side and only 88 on the

other side. The high voltage winding obviously had shorted turns. There

were no external signs of burning or leaking tar. However during

cleaning, the material on the chassis around the power transformer was very difficult to

remove even using lacquer thinner. It may have been some sort of wax

that had leaked from the transformer.

-

The unusual tapped speaker field coil, cone, and voice coil were OK.

It is very difficult to replace a speaker having a tapped field coil, since

in this case the tap location determines the output tube grid bias.

-

The antenna and oscillator coils as well as the IF

transformers were OK (all were tested for resistance and/or

continuity).

-

The original cloth covered power cord and plug were OK but

had one area that would need to be repaired to be safe.

-

The original speaker cable was OK.

-

There were two wire wound resistors (one a tapped Candohm

type unit). Both were OK. All remaining resistors were old style dogbone types.

All were significantly out of tolerance,

-

All supplied tubes tested good (the 6F7 triode section was

marginal).

-

The wire wound volume control was bad. Its total resistance

was unstable and had only intermittent contact from the center terminal to

either end terminal as the control was rotated.

-

The power switch was initially bad, but responded to a good spray of

GC Big Bath cleaner through holes in the housing, followed by repeated

operation.

-

The 6F7 grid cap lead from the first IF transformer was

frayed and had deteriorated. The shield would have to be removed in order to

effect correct repairs (vs. simply sliding on spaghetti tubing or shrink

tubing).

Cleaning

The dust was first removed using an air compressor. After removal of the dial assembly and tuning capacitor, the

tacked in filter capacitors, the antenna coil and its shield and power transformer, the chassis and remaining top components were cleaned using

lacquer thinner, GoJo (white) Hand Cleaner, 00 steel wool, and

toothbrushes.

Restoration Strategy

Since almost all of the original parts were still in place, I decided to try

to retain the

original top and bottom chassis appearance to the extent possible. All

original capacitors would be rebuilt in their original containers (restuffed). Any out of tolerance

resistors would be replaced with the same types if available. The power

transformer would have to be replaced, hopefully with a similar unit. I would

attempt to reproduce this missing filter capacitor block - chassis mounting

holes and a shadow on the chassis indicated its size and shape.

Repairs

Power Transformer

The original power transformer was removed from the chassis for

inspection. It was hopelessly burned inside!

The primary winding was open, and the high voltage secondary

indicated shorted turns - one side of the center tapped winding measured only 8

ohms, and the other side 88 ohms. It was not clear what caused the

original failure, since the filter capacitors had been replaced recently. There

were no shorts from B+ to ground, even though all the paper-wax capacitors were

original. There were no shorted or gassy tubes. It could be that the

previous owner replaced the filter capacitors without first testing the

transformer. This is apparently quite a common practice with new or

inexperienced antique radio collectors.

The original transformer supplied three 6.3 volt tubes plus a

pilot lamp (1.75 amps total), and a 5 volt 2 amp rectifier. It was a horizontal mount unit. I

just happened to have a parts chassis for a Stewart Warner model 3043 in

stock. The transformer in that chassis was good, and was a horizontal

mounted unit also. It supplied four 6.3 volt tubes plus a pilot lamp, and a 5

volt 2 amp rectifier. The current draw on the filament windings for both

sets was identical even though the tube count was different (the Stewart Warner

used a 6K6 output tube, and the Grunow uses a 42). So I decided

to install the replacement transformer to replace the original. The fit

was acceptable, although the replacement transformer was slightly smaller than

the original unit.

Tuning Capacitor

The tuning capacitor was cleaned using my old Heathkit

ultrasonic cleaner and dilute ammonia. It would not all fit in the cleaner

at once, so several cleanings at different angles were needed. I normally remove the mica

trimmer insulators before cleaning in order to avoid damage. Before

removing the mica, I note the original position of the trimmer screws on the

clock, then note the number of 1/2 turns to fully tight. This is done so that

the trimmers can be returned close to their original settings after cleaning. The capacitor was then cleaned using

soap, water, and toothbrushes. After drying with a heat gun, the bearings and grounding

fingers were lubricated using automotive distributor cam lubricant.

Volume Control

The volume control was removed from the radio and disassembled.

It was a wire wound type with a fixed resistance mechanical stop. The wiper and spring were

first removed. The rivet holding the center terminal was drilled out and

removed. On the inside, this rivet along with a flat washer retained the

resistance element. The end terminals are not physically attached to the

resistance element - the connection relies on pressure supplied by the retaining

rivet and washer. Any dirt or corrosion will result in an intermittent connection. The

resistance element was then removed and carefully cleaned using lacquer thinner

and a tooth brush. The

wiper, spring, and center rotating contact were also cleaned. The resistance

element was then reinstalled and the rivet replaced using a 4-40 x 1/2" brass

round head machine screw, plus the original flat washer. A 4-40 nut retained the

original center terminal. One must carefully note the orientation

of the resistance element as well as the wiper during disassembly and

reassembly, otherwise the minimum resistance and taper will not be correct (ask me how I know that!) After these repairs, the total

resistance was OK. The minimum resistance measured about 400 ohms, which

seems reasonable (specification is 350 ohms).

Resistors

The radio uses two wire wound resistors, both of which were OK.

All five other resistors were 1/4 watt "dogbone" type carbon resistors. ALL of these

original resistors had drifted out of

acceptable tolerance range, and would have to be replaced. In most cases,

I would replace an original resistor only if it was not within +/- 20% (or

marked tolerance). Any "dogbone"

resistors would be replaced with the same type resistor.

I keep a stock of NOS and used "dogbone" resistors, and buy all I can

on eBay and radio swap meets! Of course, most of these resistors, even NOS resistors,

would have also

drifted in value and no longer have their marked values. My solution is to

find a replacement resistor of the correct value and size as measured (ignoring the

markings), and then repaint it to the needed value codes using enamel hobby

paint!

I was able to find suitable replacement resistors in my

stock of "dogbone" resistors. Here are the repainted replacement

resistors:

Filter Capacitors

The original filter capacitor block had been removed. The

mounting holes, plus a shadow on the inside rear chassis, indicated its size.

And the Riders documentation indicated its location and height relative to the

power transformer and other parts. The original was a dual 8mfd @ 350 volt unit

with a common positive lead. The capacitor apparently used wire leads. The

revised schematic lists the wire colors used. I was able to fabricate a

cardboard box using cardboard from the back of a writing tablet. Two 10mfd

450 volt capacitors were installed inside the box. The radio requires a

common positive lead and two separate negative leads. The box was spray

painted, and a label fabricated using the correct Grunow part number and

capacitor values. Here is the reproduction capacitor:

Paper Capacitors

The paper capacitors used have no markings

other than the Grunow part number (which agree with the schematic) and a

"ground" symbol, which I assume means "outside foil".

They were likely made in-house. All paper capacitors were rebuilt in their original cases

using modern 630 volt film capacitors in order to maintain the original

under-chassis appearance. I remove the capacitor from the radio by unsoldering its

leads. The lead lengths and any insulating sleeving lengths are then

noted. I take notes of which lead goes where in the radio, and identify

the capacitor using marking tags (which note the part identification and the

location in the notes where it was removed). Here

is my restuffing process for this type of capacitor. And here are some

examples of restored Grunow capacitors from this radio:

Other Repairs

The pilot lamp was replaced with a #40 bulb (6-8 volts, 0.15 amp, screw

base). There was no marking as to type on the original bulb.

The line cord had one area that required repairs. The outer cloth

insulation was missing and the inner lead insulation was starting to fray. The

cord was cut at this point, spliced back together, and insulated with heat

shrink tubing.

The 6F7 grid lead from the second IF transformer was frayed and had to be

replaced. The grid cap was removed followed by the IF transformer shield.

The transformer was then removed from the shield - its connections were not

disturbed. A new lead was attached to the coil and the lead routed through the grommet

in the shield. The coil was then returned to its shield, the shield

reattached to the chassis, and the grid cap reattached to the new lead.

Cabinet

The cabinet was in excellent shape. It was cleaned with GoJo hand cleaner

and 00 steel wool.

The

grille cloth was slightly loose. It was re-positioned and reattached to

the cabinet to eliminate sag. The type of cement used allowed careful

localized removal of the cloth in the affected areas. The cloth was

stretched then simply pressed back against the cabinet. The original glue

grabbed it and retained it.

Testing

After the radio was completely reassembled, power was applied through a

wattmeter and fused Variac. Power was brought up slowly while monitoring

the B+ voltage and the wattmeter. The radio came alive and worked - no assembly errors! The radio was then

aligned.

Restoration Results

Most of my restoration objectives were met, but not all. There was no

intention of restoring the set to factory new appearance! My objective is

usually to reverse any prior servicing and make the radio appear to have never

been repaired. I do not go so far as to artificially "age"

solder joints, as do some collectors! Nothing gives away a restoration

faster than bright and shiny solder joints. Here are some of my

"misses":

- Replacement power transformer

- Reproduction filter capacitor block

Chassis Before and After Restoration

Chassis Before

|

Chassis After

|

|

|

After Restoration Photos