Zenith 5D625 (5-D-625) Restoration

|

The Zenith 5D625 from 1942 is a 5-tube AC/DC Superhet with Wavemagnet

loop antenna. It only receives the Broadcast band. The cabinet

is walnut veneer with photo-finish (picture of wood) trim. Other models share the same

chassis 5B01 including the 5D610 and 5D610W bakelite sets. The schematic for the

5D625 can be found on-line at Nostalgia

Air. Any references to part numbers refer to that schematic.

The radio had seen typical repair shop type servicing in the past. I decided to try to

reverse all previous servicing to the extent possible, yet get it working. |

My

antique radio restoration logs

Condition As Found

This radio was purchased on eBay. The cabinet and knobs were

in excellent condition. The power cord had been cut off and the radio sold as not

tested. The often missing original back

cover was present but very fragile.

Previous Repairs

-

All the tubes were replacements. Two were metal types,

not used by Zenith.

-

Three wax/paper capacitors had been replaced: C2, C3 (line

bypass capacitor) and C7. All replacement capacitors were CD branded,

but were different types and ages. The original filter

capacitor was still in place.

-

All of the original wiring and resistors were still in place.

-

The volume control and switch had been replaced.

Survey

At first observation, the radio was a typical 5 tube AC/DC

superhet using octal tubes. Like in the previous year Zenith models (e.g.

6D525), it used a 12K7GT (with a grid cap) rather than a 12SK7GT in the IF

amplifier stage. When I pulled the chassis, I could not find an output

transformer! It was not mounted on the speaker nor under the chassis. The

speaker was original (per the parts list) and was a field coil type. But there

were only two leads to the speaker. One lead was from the 50L6 output tube

plate, and the other from B+. The leads to the speaker went to the field

coil! So somehow, the speaker field coil not only magnetized the core, but

also acted as the output transformer. On the schematic diagram, there is an

arrow pointing to the usual position and connections of the output transformer,

but labeled "speaker field". The field coil in this case is NOT used

to assist with B+ filtering - the radio used resistors for this purpose. I have

never seen this before used in any radio. When I asked about this circuit

on Antique Radio Forums,

someone recalled seeing at least one other example of this circuit.

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. I usually never apply power to a radio before

restoration, even through a "dim bulb tester" or variac "to see

if it works". But there was signs of damage where the speaker leads

enter the combined field coil/output transformer, and there were bare areas or

the wiring exposed. Perhaps someone was trying to measure the field

coil resistance? I had to know if this speaker was working. So I applied

power through a watt meter and variac and monitored the B+ using my DVM. I

slowly applied AC power in increments of about 10 volts, allowing plenty of time

for the capacitors to reform before increasing the voltage. At about 70 volts

input, the radio started making noises and some stations were received. But the

B+ started dropping - a symptom of leaky capacitors. So I stopped the

test, satisfied that the speaker was working. I did learn that the volume

control and tuning capacitor were "scratchy" - useful information.

If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio for parts rather than

to restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise.

-

The AC power switch was was initially bad, but responded to a quick spray of

GC Big Bath.

-

The original rubber AC power cord was cut off. The remnants were very stiff

and badly deteriorated.

-

The speaker cone and field coil were OK..

-

All RF coils and the IF transformers were OK.

-

The pilot lamp was burned out.

-

The 50L6GT tube was good. The 35Z5GT was bad (open filament). This tube acts

as a fuse if there is a B+ short or bad filter capacitor. This usually also

takes out the pilot lamp. The remaining tubes were weak (also inappropriate

metal types). The burned-out 35Z5 is likely what killed the radio.

-

All resistors were in tolerance, including the wire wound types.

-

Most of the wiring was rubber covered. If moved even the slightest amount,

the insulation would fall off. All of this wiring would have to be

replaced, including the leads to the two IF transformers. The cloth covered

wiring to the pilot lamp socket was shorted inside the socket, and one of

the leads to the speaker field coil (cloth covered) was frayed and in danger

of shorting to the chassis.

-

The tuning capacitor drive pulley was loose on the tuning capacitor shaft,

resulting in backlash when tuning.

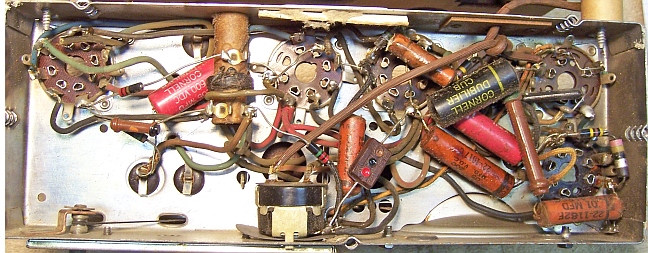

Repairs

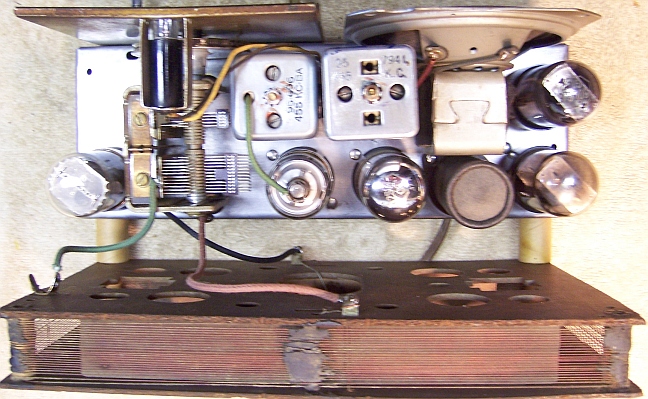

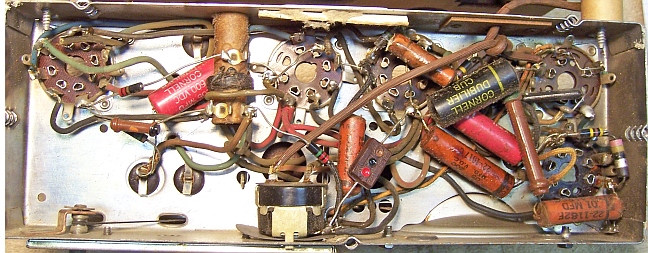

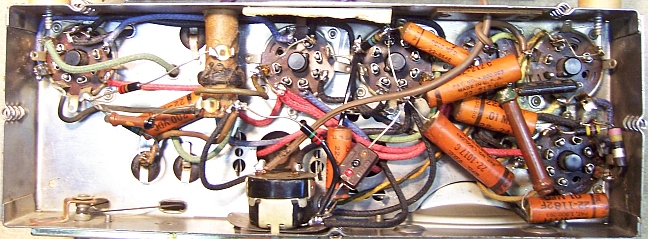

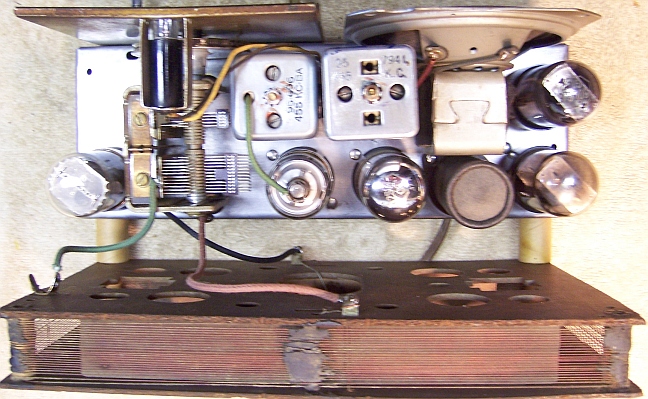

Before starting repairs I made BEFORE photos of the chassis top and bottom. I use these photos to ensure that replacement parts and

wiring are placed as close as possible to their original positions. Some

radios are subject to problems (such as hum pickup or oscillation) if wiring is re-routed or

lead dress is not the same as the original.

In Zenith schematics, all resistors and capacitors having the same

value have the same part number call out. So for example, there may be

multiple R2's or C4's on the schematic. Before I start work on the chassis

I annotate the schematic and under chassis photo so that all parts have unique

identifiers. I usually add an alphabetic suffix, so that the part numbers

are thus R1A, R1B, etc. I then annotate the chassis photo with these unique part

numbers with a red felt-tip pen.

All tubes were removed. The chassis was very clean, with no rust - just

very dusty. It was first cleaned off with a vacuum cleaner. The chassis

was then cleaned with a tooth brush and vacuum cleaner to remove any remaining

dust. The tuning capacitor was not removed for cleaning, since it is

mounted using bent-over tabs through rubber grommets. The tuning capacitor was

cleaned by spraying it with GC Big Bath spray cleaner.

Wiring

The AC line cord was replaced with a replacement vinyl cord with molded plug.

All of the rubber covered wiring was replaced using cloth covered stranded and

solid wire available from Radio Daze and

other sources. I use their "unrated" wire rather than their 600 volt

rated wire (which is much too large for antique radio repair work). It is

available in 8 colors. One of the colors used in Zenith radios (a grayish

green) is not available. I normally use green or black to replace this

wire. Their solid and stranded wire is 20 gauge, which is really too large for

Zenith repairs (original Zenith solid wire is about 24 gauge). But that is

all I have been able to find in cloth covered wire.

One of the leads to the speaker field/output transformer was replaced using a

similar type wire from my junk box. It was spliced to the lead on the speaker

after cutting and stripping it close to the field coil. Afterward, both speaker

leads were reinforced using several layers of GC Service Cement, followed by a

layer of cloth tape, and do not like to use modern plastic covered wire.

Tuning capacitor pulley repairs

The hub of the tuning capacitor pulley was pot metal. Originally it was

inserted through a hole in the pulley and then peened over to retain it.

But wear had allowed some rotational motion. A previous owner and

attempted to solder the hub to the pulley. But that did not work, since one

cannot solder to pot metal! I did not want to risk damaging the pot metal

hub by banging on it with a hammer! So I cleaned off all the solder I could. I

then drilled a small hole through both the pulley and the edge of the hub using

a numbered drill and Dremel Moto Tool. I then inserted a tapered clock pin into

the hole and clipped it short. I then applied epoxy to the area around the pin

as well as on the back side of the pulley in order to secure the pin in

place. That seemed to work. I'm not sure how long this repair will

continue to work, but it did eliminate backlash when tuning.

Filter Capacitor

The original power supply filter capacitor C9-C10-C11 was removed and restuffed.

It was a 30+20+20mfd @ 150 volt twist lock type capacitor. It was restuffed using two

22mfd 160 volt radial capacitors and a 22mfd/160 and 10mfd/160 volt capacitor in

parallel (I did not have a 33mfd/160 volt in stock, and the 33mfd/350 volt I did

have was

too large to fit in the can). My

procedure for restuffing FP type can capacitors is as follows (there are many

discussions and examples with photos on Antique

Radio Forums):

- Remove the cardboard cover. In this case I had to use a heat gun to soften the tar

holding it to the can.

- Uncrimp the bottom using diagonal cutters (try to

minimize damage to the outside of the can)

- Remove the mounting ring, the outer terminal board, the almost liquid

gasket material behind, and a second fiber board, cutting the aluminum leads to the capacitor body to free up the terminal

boards.

- Remove the can contents using a heat gun to release the tar, followed by a

thorough cleaning using mineral spirits. In this case, the foil roll

could be removed without heating, and the remaining tar removed by

mechanical means.

- Remove the sealer/gasket material between the two terminal board layers

using a small screwdriver and an Exacto knife. Clean off any remaining

material using lacquer thinner. Both sides of the two terminal boards

must be very clean, since they will be glued together using epoxy. The

two terminals are secured between the two boards.

- After the epoxy hardens, connect the three replacement capacitor positive leads to the original terminals by

drilling small holes through the terminal boards close to the terminals,

passing the leads through, and soldering them to the terminals on the

outside.

- The common ground lead is passed through a small hole drilled near

one of the capacitor ground/mounting tabs. The hole is located by

temporarily replacing the mounting ring (there is a tab that fits into a

notch on the outer terminal board) and marking the location near one of the

three mounting twist tabs. This lead is not soldered

to the ground lug until after the capacitor is secured in the chassis

mounting wafer (otherwise the solder would prevent the lug easily passing

through the hole in the mounting wafer or could damage the wafer - ASK ME

HOW I KNOW THAT).

- Reinstall the terminal boards with attached replacement capacitors and the

mounting ring and restore the crimp

around the base. I start the crimp using a screwdriver and then

flatten it out using a plastic tipped hammer.

- Reinstall the cardboard cover (it was not glued - just held by friction).

The cover hides any signs of the bottom crimp being disturbed. Be

aware that the capacitor body is electrically HOT (connected to one side of

the AC line), so the cover is an important safety

feature. The chassis itself is isolated from the AC line by a

capacitor.

Wax/Paper Capacitors

Three original Zenith wax/paper capacitors had been replaced in previous servicing:

C2 (22-829, .05mfd/200v), C3 (22-1017, .05mfd/200v) and C7 (22-243,

.01mfd/400v). I maintain a stock of branded (Zenith, Philco etc.) as well as generic

(Sprague, CD etc.) dud capacitors just for this situation. I was able to find

original Zenith duds for C2 and C7. But I did not have a Zenith 22-1017 in

stock, and was forced to use a Zenith 22-212C instead (.05mfd/400v).All of the original Zenith paper capacitors as well as the Zenith duds

were rebuilt in their original cases

using modern 630 volt film capacitors in order to maintain the original

under-chassis appearance. My re-stuffing process is documented here.

Cabinet

The cabinet was cleaned using GoJo (White) hand cleaner, applied and then

wiped clean using Toolbox White Rags (soft, smooth paper towels made from rags). The

knobs were cleaned using my old Heathkit ultrasonic cleaner and dilute ammonia,

followed by rinsing and drying.

Testing and Alignment

Once the radio chassis was reassembled and the tubes installed, power was brought up

slowly using a variac. A DVM monitored the B+. The radio came to life immediately and worked.

The tuning capacitor was scratchy when adjusted. I first thought it had plates

that were rubbing. To check this, I temporarily disconnected any leads from both

stators. I then connected a 9 volt battery and pair of antique radio

high-impedance head phones in series between each stator terminal and the

capacitor frame. As the capacitor was rotated, no sounds were heard. This

meant that the plates were not touching. The other possibility was that there

was dirt and/or grease between the rotor shaft and the brass grounding fingers.

The fingers were riveted to the capacitor frame, and thus could not be removed

for cleaning. So instead I used pipe cleaners and lacquer thinner to clean the

contact areas as the shaft was rotated. After this treatment, the scratchiness

when rotating the capacitor was gone. My normal procedure is to remove the

capacitor from the radio and clean it using an ultrasonic cleaner using dilute

ammonia solution. But in this case, I did not wish to remove the capacitor since

it is not mounted using threaded studs, but rather bent-over tabs through rubber

grommets.

For alignment I isolated the chassis using an isolation transformer (since my

signal generator is grounded and this is a hot chassis radio). But alignment of

the IF transformers was difficult. There was considerable hum and distortion,

and also the set could break into oscillation as the IF transformers were

peaked. So I got the IF transformers close to their correct frequencies and then

disconnected the generator and peaked the transformers using a broadcast

station. The antenna and oscillator trimmers were peaked using this same method

- a known broadcast station at 1400 kHz on the dial.

Restoration Results

Most restoration objectives were met. I was able to restore the radio to its

original condition prior to servicing except for one wax/paper capacitor. That

capacitor Zenith 22-1017 was replaced with another Zenith part with the same

value (different voltage rating). The non-original volume control and switch

were left in place, since they were good, and good original parts are likely not

available.

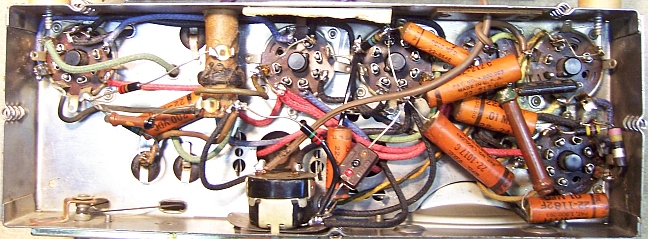

Chassis Bottom Before and After Restoration

Restoration Completed Photos