Zenith Model 6G038R (6-G-038R) 2nd Restoration

|

The Zenith model 6G038R (6-G-038R), 1946 model year, is a

large tabletop 6-tube superhet circuit radio that operates from AC, DC or dry batteries. This

is the second example of this radio that I have restored. This example had seen

minimal servicing in the past. The cabinet in this example was not as good

as the first one I restored, but had its original finish (the first example had been

refinished). The chassis in this example was almost original.

The schematic for the Zenith 6-G-038R can be found on Nostalgia

Air. Any part numbers in this log will refer to numbers on that schematic. |

My

antique radio restoration logs

Overview

This radio uses 1.5 volt battery tubes although it can operate

on 117 volts AC or DC. The radio's large cabinet accommodates the

battery, which supplies 9 volts for the tube filaments and 90 volts for

B+. It receives the standard broadcast band and two short wave bands and has

the Zenith Radiorgan tone

control system. The circuit is similar to Zenith Transoceanic and

suitcase style portable radios, however instead of a Wavemagnet (loop antenna) this radio uses an

extendable whip antenna (Waverod) for local stations and can accommodate a long wire outdoor antenna.

The circuit is quite complex due to the fact that all the filament type tubes

are in series, which complicates the proper biasing and AVC operation.

Also, lots of bypass capacitors are needed to prevent tube interaction and

feedback. The small compact chassis and high component count makes

servicing difficult. This type of radio was often purchased by rural

customers who currently had no electrical service. They could use the

radio on (expensive) batteries and not have to purchase a new radio when

electrical service arrives.

Previous Repairs

-

Only one of the tubes (3Q5GT) was branded Zenith, and thus most were likely replacements.

-

The dial cord had been replaced (spliced) - the tension spring looked

original. The dial cord had been wound in the wrong direction on the tuning

shaft, which must have confused the operator since the dial pointer would

rotate in the opposite direction as the tuning knob!

-

All resistors and capacitors appeared to be original.

-

The 1A7G tube had been replaced by a 1A7GT and the required tall tube

shield was missing (in my first restoration of this same model, the tall

shield was still in place but a 1A7GT tube was installed).

-

The original chassis bolts had been replaced by self-tapping screws

and washers. The chassis must have been removed in order to replace

the dial cord, and perhaps the original chassis bolts had not been replaced.

Original Condition

The radio had been purchased on eBay. It was sold as not working.

The cabinet finish was original, but had some rather serious scratches, dings, finish wear and oxidation (it was quite dark). The grille cloth

was original and was in excellent

condition The knobs were original and in good condition with minimal warping. The dial glass was intact, and the dial

glass rubber extrusion was still intact, although I'm sure it would crumble if

disturbed! Several cabinet

glue blocks

had broken loose, likely due to rough handling in shipping. Some of the rubber covered wiring was still supple and in great condition -

including the leads to the Radiorgan tone control switch panels - very unusual.

The battery cable had some leads that would have to be replaced. The chassis was quite dirty, but not rusty.

The insulation on the rubber covered wiring under the chassis would fall off,

exposing bare wire, if moved even the slightest amount. Every effort was made to

retain the original wiring where possible.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio or keep it for

parts rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise.

It was interesting that a handful of paper capacitors in this

radio were branded Aerovox or Solar without Zenith part numbers. This was

also true in my first example of this radio. All other Zenith

radios dated after about 1932 that I have restored had either Zenith branded capacitors, or else other

brands which had Zenith part numbers (22-xxx). The non-Zenith capacitors

appeared to be original based on examination of the associated solder joints. Inquiries on Antique

Radio Forums yielded opinions that in 1946, right after WWII when this

radio was made, manufacturers were scrambling for parts, and might have used

whatever was available at the time, even if not branded Zenith. This may

also have applied to the tubes, since only one was branded Zenith in this radio

(but could have been original for the same reason).

-

The output transformer was OK.

-

One primary winding of the antenna coil (the 23 ohm winding) was open - a

potential showstopper! The detector coil and oscillator coil were OK.

-

The IF transformers were OK.

-

The tuning capacitor mounting grommets were intact, although hardened and

thus providing no cushioning.

-

The chassis washers were hardened and crumbling.

-

The rubber covered wiring to the Radiorgan tone panels was OK, but the

battery cable had several frayed leads that would have to be replaced (even

though I did not plan on using batteries).

-

The power cord was original and falling apart - it would have to be

replaced..

-

Candohm resistor

R13-R14 was OK. Originally one section was 21% high. I applied

my standard Candohm "fix", which is to squeeze the metal case near

each terminal using a small C-clamp. The insulation for this resistor looked to

be in good condition, so the resistor was left in place. After the

squeeze, both sections were in tolerance and one section almost exact.

-

R12 (140 ohms, 10%, Zipohm) was out of tolerance. When later examined, it

was broken and would have to be replaced. The original was a thin flat sand

type resistor (this resistor already had been replaced in my first example of this

radio).

-

Six resistors were out of tolerance. Three were 1/4 watt old style dogbone types.

The remainder were 1/4 watt or 1/2 watt carbon composition types.

-

Four of the tubes were bad - they had open filaments and shorts. Only the 117Z6GT

and 3Q5GT (Zenith) were good..

Antenna Coil

Before starting restoration I had to deal with the potential showstopper

issue with the antenna coil, which had an open primary winding (the one used with

an outside antenna). The coil was covered with dirt and dust which was

imbedded in the wax coating. So it was not obvious which of the multiple

coils was open. So I decided to remove the coil from the chassis for

closer inspection and possible repairs or rewinding. This was a very

difficult task, since the terminals of the coil under the chassis, as well as

the mounting studs, are under the band switch! I started disconnecting

wiring and other components from the lugs, while making careful notes about wire

colors and where each wire was routed. Some thicker bus wiring as well as

one capacitor lead was cut rather than unsoldered in order to prevent possible

damage to the coil, or if there was no room for a soldering iron! The capacitor would have to be removed and restuffed

anyway. The bus wiring and capacitor would be replaced (reattached to the coil terminal)

before the coil was re-installed. It is easier to reattach some leads or

components if they are attached before the coil is fully fastened to the chassis

(while hanging in mid air).

Once removed from the chassis, the coil was heated using a heat gun to remove

most of the wax and dirt. I simply let the wax drip into a puddle on a piece of

newspaper. The primary winding that was open was located. It was the

very top winding, and was bank wound. The break was found at the point where the

inside (start) of the winding was routed over the top of the coil form and then

down to a terminal on the bottom of the coil form. This left about 3/8" if wire available

for a splice - very little room for error! A piece of #28 solid bus wire was routed from the

bottom terminal up inside

the coil form to a small hole drilled near the primary winding stub. The

stub was carefully scraped clean of enamel and tinned, then attached to the solid

wire. Measurements of all windings now indicated the coil was OK. I then

melted the puddle of original wax left and poured it onto the coil, and then

smoothed it out as best I could using my heat gun. The coverage was not as

thick or uniform as it was originally, since I did not have enough wax to dip the coil.

Repairs

Before starting any repairs I took photos of the chassis top and bottom so that routing of wiring and component placement could be restored.

Lead dress is often critical in radios. When I replace a component, I

always remove the original part completely from a terminal. Other

components connected at the terminal are protected from heat using old medical

clamps (hemostats). Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

The tuning capacitor and the two

filter capacitors were removed for cleaning access to the chassis. The filters

later would be restuffed. The top of the chassis was cleaned with GoJo hand cleaner and 00 steel

wool. The tuning capacitor was cleaned in my old Heathkit Ultrasonic

cleaner after removing the trimmer hardware and mica insulators. The

capacitor was then cleaned using soap, water, and toothbrushes. In order

to return the trimmers to near their original positions, before removing the

screws I noted the original position of the screws (on the clock) and how many

half-turns (and fractions) to completely tight. Once the cleaning and

drying was completed, the trimmer hardware was reinstalled and the trimmer

screws returned to where they were by fully tightening the screws then backing

off the documented number of half-turns and fractions. I like to get them

close to where they were originally before alignment. After drying, the bearings were lubed with

automotive distributor cam grease.

The Radiorgan tone control contacts were cleaned in my old Heathkit

ultrasonic cleaner, using dilute ammonia. Only the fixed and moving switch contacts were

cleaned, and were carefully rinsed and dried afterwards.

The dial drive cord was replaced with a suitable black dial cord

material. The original spring was re-used.

The power cord was replaced using a modern brown vinyl cord with molded

polarized plug (the original was brown rubber with a molded plug). Replacement tubes were installed for the four defective

tubes. The blue and black leads in the battery cable were replaced.

The remaining two were OK.

Resistors and Capacitors

In most Zenith schematics, all parts which have the same value or type have

the same reference number. For example, there may be multiple occurrences

of R1 or C2. Before starting restoration, I normally add a suffix forming

unique identifiers: R1A, R1B, etc. That way I can make the correct

reference in my notes. I usually also annotate the under chassis

photograph with the parts callout.

All the original Zenith branded paper capacitors were rebuilt in their original cases

using modern 630 volt axial film capacitors in order to maintain the original

under-chassis appearance. Here is the process I

use. I reseal the cardboard tubes using rosin

salvaged from servicing RCA Radiola superhet catacombs (it melts at a low temperature and will not damage

the replacement capacitors). The paper capacitors that were not

Zenith branded were replaced with Zenith duds having the correct Zenith part

number. These were also restuffed with new 630 volt film capacitors. I collect Zenith and other

branded capacitors (Philco, RCA, GE etc.) just for this situation, and also to

reverse any prior servicing where original parts have been replaced. Since all

capacitors listed in the parts list had Zenith part numbers, I assumed that

later examples of this radio would have all Zenith capacitors, once the post-war

parts shortage was alleviated.

Both original filter capacitors (C36-C37-C38 and C27-C28) were restuffed to

preserve the chassis appearance. The original cans were restuffed using the

following technique:

- The cardboard covers were removed by heating with a heat gun to soften the

tar which retained them.

- Excess tar was removed from the insides of the covers mechanically, and

cleaned from the outside of the inner metal cans using lacquer thinner.

- The crimp around the base was removed using several tools, such as

diagonal cutters and small screwdrivers.

- The ground lug ring was removed.

- The three layer terminal board assembly was removed intact after the aluminum leads connecting the terminals to the body of the capacitor were

cut. The stubs were then cut flush with the bottom of the terminal

board and the board cleaned using lacquer thinner. The assembly

consists of two fiber insulators separated by a rubber-like gasket material.

- The old can contents were removed by pulling on the projecting stubs.

Sometimes more aggressive methods are necessary if the contents are tightly

packed or are firmly attached with tar.

- The old can was cleaned out mechanically (the cans do not need to be

totally clean inside).

- Holes were drilled through the terminal board close to

the terminals as well as close to one of the ground lugs. The ground lug

ring was temporarily aligned with the terminal board so that the proper

location for a common ground lead could be determined. There is a

projecting tab on the ground lug ring which matches up with a notch in

the terminal board.

- The new components were installed inside the old can. Leads for the

common ground and positive leads were routed through the drilled holes

and attached to the original terminals (later secured by soldering when the

original leads were reattached). I use radial type electrolytics in

order to

save space. Thin insulating spaghetti tubing was used where needed to

prevent shorts. Capacitor C36-C37-C38 (10+20+30@150 volts) was restuffed

using 10, 22, and 33mfd @160 volt capacitors. Capacitor C27-C28

(200@10 volts, 40@150 volts) was restuffed using 220mfd@10 volts and

47mfd@160

volt capacitors. On the parts list, C27 was listed as 200mfd @ 10

volts. On the actual capacitor case C27 was listed as 20 volts. The

capacitor I installed was rated at 10 volts (I ordered parts from the parts

list). I really should have used a higher working voltage capacitor

here, since the capacitor could be damaged if the filament string opens up.

- The ground lug ring and terminal board were reinstalled and the crimp on the base

restored using a variety of tools, finishing off with a tack hammer to

smooth out any lumps.

- The cardboard covers were reinstalled, but not cemented in place for ease

of future servicing.

R12 (140 ohm, 2.5 watts, 10%, Zipohm) was replaced by a 130 ohm 4 watt wire-wound

resistor that measured 142 ohms.

Two 2.2meg dogbone resistors were replaced with 1/4 watt dogbone

resistors that had drifted within tolerance of the needed values. These were

repainted as 2.2meg resistors using hobby paint. A 470K 1/4 watt dogbone resistors

was also replaced by a repainted dogbone resistor that now measured within

tolerance. All the other resistors needed were either 1/4 or 1/2 watt carbon composition types (new stock is available, but differs in

appearance from the originals).

Testing and Alignment

Once the radio was reassembled and the tubes installed, power was brought up

slowly using a variac. Two DVMs monitored the B+ and the critical filament voltage. The

radio worked immediately on both broadcast and both short wave bands. The Radiorgan

controls worked correctly. With 120 volts input, the B+ was

correct,

but the filament voltage was slightly low (8.4 volts vs. 8.7 volts).

Restoration Results

Most restoration objectives were met, but there were a few misses:

- The R12 replacement differed in appearance from the original

- The replacement carbon composition resistors differed in appearance from the

originals

- Some rubber covered wiring was replaced by cloth covered

wire. One of the original colors (a brownish-gray) is not available, so

another color was used.

- The as found self-tapping chassis bolts and washers were

re-used. There are no currently available replacements for the

10-32x7/8" hex slotted washer head screws originally used. One would

need to find a set of originals. I had only two originals in stock.

- I did not have Zenith branded tubes available for all

replacement tubes used.

|

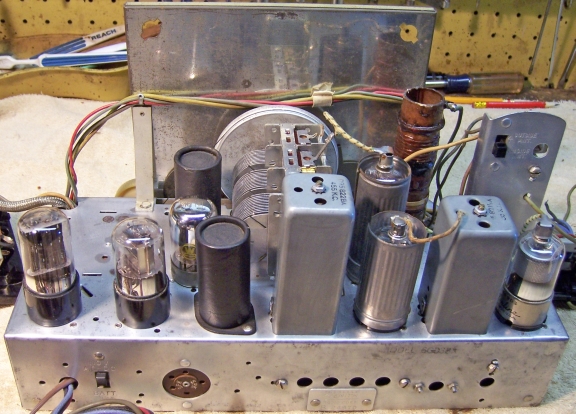

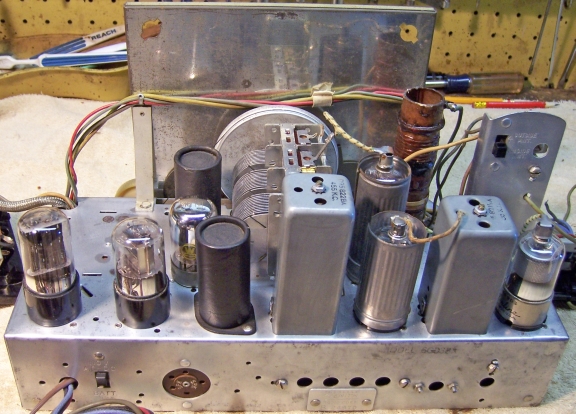

Chassis Before Restoration |

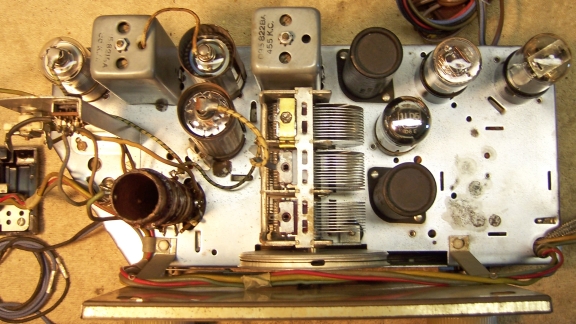

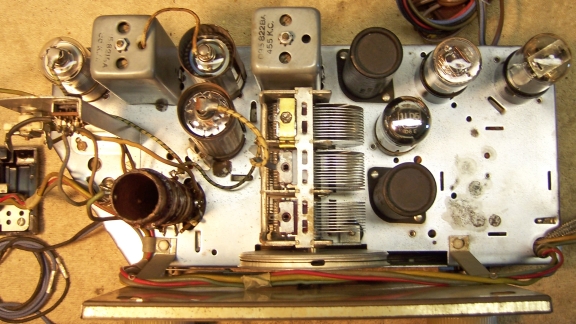

Chassis After Restoration |

|

|