Zenith 8S434 (8-S-434) Restoration

|

The Zenith model 8S434 (8-S-434) from 1940 is a tabletop

8-tube AC superhet circuit radio which has a unique cabinet design with

decorative turned columns.

It receives the standard broadcast band and two short wave bands, has

"automatic" or push-button tuning, and the Zenith Radiorgan

tone control (but has only two controls rather than the usual 5 or 6) The

radio had its original speaker, but the chassis had been changed out to a

5724, which is used for the model 7S434 and similar models. A

correct chassis (5810) was later found and restored. The Wavemagnet

antenna that came with the set was for the 5724 chassis, and not correct

for chassis 5810.

The schematic for the Zenith 8S434 Chassis 5810 can be found on Nostalgia

Air. Any part numbers mentioned will refer to numbers on that schematic. |

My

antique radio restoration logs

Overview

I had originally restored the chassis that came with the radio

(5724) and the radio worked, even though the speaker (49-301) was designed for

chassis 5810. The 49-301 speaker had a different field coil resistance and likely

a different output transformer than the speaker used with chassis 5724. It

always bothered me that the chassis was incorrect. I eventually found a

correct chassis on eBay. It was complete with escutcheon and tone

switches, but had no speaker. This was OK since I had the correct

speaker!

The Wavemagnet that came with the radio was likely correct for

chassis 5724, however it did not have a local/distant switch as shown on the

chassis 5724 schematic. It was also not correct for chassis 5810, since it had a single 5-pin plug. The 5810

chassis expects a 4-pin plug (only 3 used) and a two pin plug (one large and one

small pin, similar to those used in standard base tubes). But it did fit

the back of the radio correctly! I have not yet determined what radio it

came from, but it was NOT the original back on the 8S434. So my original

8S434 was essentially a Frankenradio! My strategy was to modify the Wavemagnet antenna to work with chassis 5810 (hopefully).

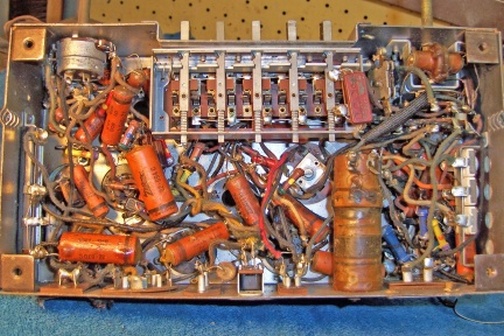

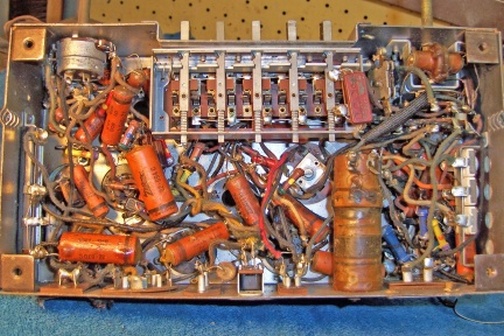

This is a very difficult radio to

service. The chassis is very compact, and the automatic tuning unit is

under the chassis. Some parts cannot be accessed without partial

disassembly. There are also errors in the Riders schematic. For

example, the schematic shows two 68 ohm wire wound resistors (R8) connected in

series between the 6K7 cathode and B+! In actual fact, these two resistors

are in parallel and connect to B-. Some of the bypass capacitors have

different values than listed in the schematic. C24 (.25mfd) was not

installed. The broadcast band padder capacitor is not pictured nor

mentioned in the alignment instructions. Here is what the chassis looked

like prior to restoration:

In Zenith schematics, all resistors and capacitors having the

same value have the same part number callout. So for example, there may be

multiple R2's or C4's on the schematic. Before I start work on the chassis

I annotate the schematic so that all parts have unique identifiers. I

usually add an alphabetic suffix, so that the part numbers are thus R1A, R1B,

etc. Once chassis photos are taken, I then annotate the photo with these

unique part numbers.

Previous Repairs

-

All the Zenith branded paper-wax capacitors were original -

none had been replaced.

-

All of the original Zenith resistors were still in place.

-

The voltage doubler input capacitor C19 had been replaced,

but the main filter capacitor C20/21/22 was original.

-

The AC line cord was cut off.

-

Most of the tubes were replacements, except for the Zenith

branded 6AF5G (unfortunately weak). The two 25Z6 and the 25AC5 tube were GT types rather than the correct G types.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise. The

automatic tuning unit (push button assembly) was removed in order to gain access

to components underneath. Fortunately, only two wires had to be

disconnected. I found:

-

The short wave antenna coil marked 2 on the schematic had been partially eaten by mice! This

was a potential showstopper! All other coils and transformers were

OK, including all the automatic tuning unit coils.

-

The Wavemagnet antenna was not the correct part for chassis 5810. It

fit the radio cabinet, and appeared identical to the antennas used on other similar

Zenith sets, but it had different connectors. Another potential showstopper.

-

Two dogbone resistors and two carbon resistors were out of tolerance.

The carbon resistors were unique in appearance but quite common in

Zeniths. They appear to have metal end caps and are not much larger

than normal 1/4 watt carbon composition resistors.

-

One of the two R7's, 22 ohms 1/2 watt wire wound, had failed - completely cracked

open! This was very likely caused by the failure of C19, the voltage

doubler input capacitor (which had been replaced). The other R7 was OK.

-

The 3-section Candohm resistor was OK. The schematic noted that the

value was 28 ohms for the filament dropping section (the two pilot lamp

shunt sections are NOT used in this chassis). The resistor itself was

marked 38/10/10 ohms, but measured about 52/14/10

ohms cold. I tested the resistor with tubes in place before starting

restoration. With 122 volts in, the tubes lit up normally, but the

voltage was slightly high (the radio is rated for 120 volts according to

Riders). The voltage to the filaments was 108 volts - should have been

101 volts. After this test, the resistor measured the specified 28

ohms hot! It was left in place pending further testing.

-

C19, the voltage doubler input capacitor, had been replaced.

The original main filter

capacitor C20/C21/C22 was still in place.

-

The two 25Z6 tubes and the 25AC5 were GT types. The 6A8G,

6K7G, 7G7(1232) and 6Q7G

were good. The 6AF5G, an original Zenith, was weak (800/1500).

-

The dial cord was broken

-

Both pilot lamps were good

Repairs

All tubes and shields were removed. The automatic tuning unit was

removed. The dial scale and pointer were removed. The tuning capacitor was

removed for cleaning and replacement of the chassis grommets. The short

wave antenna coil (item 2) had previously been removed for repair (see

below). The RF amplifier sub-chassis was eventually also removed,

since there are parts inside which have to be checked and replaced, and access

is blocked by other components.

|

|

RF Amplifier Sub-chassis

Before Restoration |

The

chassis top and sides were then cleaned using GoJo white hand cleaner and 00

steel wool. After cleaning, the chassis was carefully vacuumed and gone

over with a small magnet and masking tape to remove any steel fragments that could later

cause problems.

I then took photos of the chassis

bottom so that routing of wiring and component placement can be restored.

Lead dress is often critical in radios. When I replace a component, I

always remove the original part completely from a terminal. Other

components connected at the terminal are protected from heat using old medical

clamps (hemostats). Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

At this point, the chassis appeared as follows:

The original line cord had been cut off. It was replaced by a new brown

vinyl cord.

The dial scale that came with the chassis was not in as good a condition as

the one on the 5724 chassis (wear, one significant scratch, fading). So I swapped the

two dial scales as well as the dial pointer, installing the better ones on the

5810 chassis I intended to use with the radio (the scale was not yet installed

on the 5810 chassis pending replacement of the dial cord.)

The volume control and band switch were cleaned using GC Big Bath spray

contact cleaner/degreaser, available from Antique

Electronic Supply. The automatic tuning unit contacts were cleaned

using Caig DeOxit D5 and Q-tips, followed by a cleaning spray with Big

Bath. Contact resistance (closed) was measured prior to re-installation of

the tuning unit.

Dial Cord Replacement

The extant dial cord was broken, so a replacement was installed. This

was one of the most difficult tasks in this restoration! The tuning

shaft is hidden beneath the tuning unit compensation coil, which has four

hair-thin leads that are easy to damage. It cannot easily be removed, even

if the leads are disconnected, since access to the screw and nut that retains it

are not easily accessible. The tuning capacitor and its pulley had by this

time been installed, along with new vinyl grommets. The pulley MUST be

installed before the tuning capacitor is mounted, since it sits in a depression

in the chassis top. I did not have any of the original type dial cord in

stock, so I was forced to use a thinner type. Here is the method I used to

replace the dial cord.

- One end of the cord was first routed through the right side hole in the

chassis (view front), which is under the tuning capacitor

pulley.

- The chassis was then flipped upside down.

- The end of the cord was retrieved.

- The cord was wrapped around the tuning shaft for 2.5 turns. This was

not easy, since the automatic tuning compensation coil is in the way and

must not be damaged! I fabricated a hook out of bare buss wire which

was used to grab the end of the cord as the turns were wound - assisted by

needle nose pliers.

- The free end of the cord was then routed through the LEFT side hole in the

chassis, which is also under the tuning capacitor pulley. Before

proceeding further, you must make sure that the cord winding on the shaft is

not tangled or crossed.

- The tuning capacitor pulley was positioned so that the tuning capacitor

was at minimum capacity (maximum clockwise) and the hole in the edge of the

pulley was at about the 5:00 position.

- The end of the cord from the left side hole in the chassis was then wound

in a clockwise direction over the top of the pulley, passed through the hole in the edge of the pulley, and

attached to one end the of the original spring. The other end of the

spring was attached to the tab on the pulley designed to retain it.

- The remainder of the dial cord (projecting from the RIGHT side hole in the

chassis) was wound onto the pulley in a counter-clockwise direction, under

the pulley, and back over the top of the pulley. About an extra foot of cord was left slack, since it must pass over a small pulley on the

left side of the dial scale, over the top of the dial (retains the dial

pointer) and then onto the tuning capacitor pulley and through the hole in

the edge. I used a series of test clips as well as masking tape to

keep the dial cord in place during this process, to prevent tangling.

- The dial scale was then installed.

- The excess cord was then cut, leaving about 6" slack.

- The cord was then routed correctly and tensioned. The loose end was

routed through the hole in the pulley (along with the other end) and

attached to the same end of the spring as the other end of the cord. A

knot was then tied.

- The dial pointer was then mounted and attached to the dial cord.

- The mechanism was then tested for correct operation. Adjustments

were made to the dial pointer position and tuning capacitor pulley.

Once satisfied, I secured the knots in the dial cord using Super Glue.

The short wave antenna coil, item 2, had been partially eaten by mice!

At least they did not leave any deposits on the radio chassis. Part of the coil form as well as the topmost windings had been destroyed. At

first this looked like a fatal injury, perhaps relegating the chassis to a parts

set. The coil had three windings: a primary and two secondary windings -

one for short wave (Short Wave 2), and one for police band (Short Wave 1) Before starting repairs, or

even doing my survey, I removed the coil from

the chassis - not an easy task! It is located under the small sub-chassis

holding the 1232 RF amplifier tube and filament transformer. The

sub-chassis had to be unbolted and raised a slight amount in order to gain

clearance to remove the coil. Of course, all 5 connections to the coil had

to be unsoldered.

Once the coil was removed, it was discovered that the primary and short wave

windings were still intact! The only coil damaged was the Police band

secondary coil,

which was on the top of the form. I first melted off the wax from that portion of the coil using

a heat gun, taking care not to damage the rest of the coil. I then carefully unwound the coil, counting

turns (difficult, since about 1/3 of the coil had broken turns). The

coil was in two sections: a 4-turn section at the top, then a 0.08" gap, then a 17-turn

section below. I also measured the position of the coil sections as well as the

winding direction. I measured the size of wire used using a micrometer

(6.5 mils) and

matched it up with my stocks of magnet wire, getting as close as possible to the

original wire size used. I used 34 gauge enamel magnet wire to rewind the

coil.

The gap in the coil form was first patched using a section of a donor

coil. The patch was attached using epoxy cement after that part of the form was first

cleaned using lacquer thinner to remove any remaining wax. The coil form

was then mounted in my small Unimat lathe using an improvised jig (a screwdriver

handle). The drive belt was removed from the lathe and the belt guard

opened so that the lathe could be turned by hand. The magnet wire supply spool

was held in an improvised holder fabricated from a piece of metal strapping

screwed down to the bench, and a wooden dowel. The coil was then rewound with the correct

number of turns and spacing, keeping the winding as straight as possible (the

result was far from perfect). Once the winding was complete, it was coated

with rosin salvaged from servicing RCA Radiola Superheterodyne catacombs in

order to stabilize the winding.

Of course at this point I had no idea if the coil would work properly, and if

the Police band would properly track. There is no trimmer for the

police band.

|

|

|

|

|

T2 Damage |

Wire Removed |

Form Patched |

Coil Rewound |

Wavemagnet Antenna

The Wavemagnet antenna was modified per the schematic diagram. Only

minor changes were required. The original Wavemagnet had a single 5-pin

plug. The 5810 chassis had a 4-pin socket (no center pin) and a two pin

socket with pins similar to those used in standard base tubes (such as a 6D6) -

one pin was larger than the other. I found that the pin size and spacing

was the same as those on a standard tube base. So I salvaged the fiber

base plug of an old automobile vibrator (I never throw anything away) and cut away all except the two pins

needed and the fiber web between them. It was them cleaned up using a

Dremel Mototool sander and files. The un-needed center pin of the small

plug was removed. The wiring of the Wavemagnet was then modified to match

the 5810 chassis. Only minor changes were needed. One wire had to be

added, which shorts out the broadcast band antenna coil primary winding through

the band switch in Short Wave mode. Of course, at this

point I had no idea if this Wavemagnet antenna was electrically the same as the

one I needed. It was later determined during testing the it worked

perfectly! Here are the modified and re-created plugs for chassis 5810:

Resistors and Capacitors

All the original Zenith paper capacitors were rebuilt in their original cases

using modern 630 volt axial film capacitors in order to maintain the original

under-chassis appearance. I reseal the cardboard tubes using rosin

salvaged from servicing RCA Radiola Superheterodyne catacombs (it melts at a low temperature and will not damage

the replacement capacitors). Here

is my restuffing process for Zenith capacitors.

|

In order to remove and restuff the capacitors on the right

side of the chassis, major surgery is required! The ground lead to

the three trimmers must be removed and the trimmer capacitors unbolted

and moved out of the way. The oscillator coil must also be

unbolted and carefully moved out of the way. Some of the bypass

capacitors are partially hidden by the band switch and one lead is

soldered to the chassis. Originally these capacitors were likely

installed BEFORE the band switch was installed! There is hardly

any room for a large enough soldering iron to replace these

capacitors. In a couple of cases, the original capacitor leads

going to chassis ground were cut, and the restuffed capacitor lead

spliced to the grounded stub. |

One original Zenith filter capacitor C19 had

been replaced. I purchased a dud twist-lock capacitor on Antique

Radio Forums Classifieds which had the correct diameter and approximate length, as well

as a black cardboard cover. It was an original Zenith capacitor, but

not the correct part number. This capacitor was opened, its contents removed, and was rebuilt using

a modern 33mfd/450 volt electrolytic cap. The dud capacitor I used had two

lugs. One was removed.

The cardboard cover for this capacitor is needed since the metal

case is connected directly to the AC line! The original main

filter capacitor C20/C21/C22 was 30/20/10mfd at

350/250/250 volts. It was rebuilt as 33/22/10mfd at 350/250/350 volts

using new modern radial lead electrolytics.

The two dogbone resistors that were out of tolerance were replaced by a NOS dogbone

resistor (that was in tolerance) and another that had drifted to near the correct value.

That one was repainted

using hobby paint to the correct color codes. While this resistor may

continue to drift, so will the others in the set. I wished to maintain the

original above and below chassis appearance. The two metal end carbon

composition resistors were also replaced using NOS and repainted dogbone type

resistors (1/4 watt) since I did not have any good original parts.

The defective R7 (22 ohms wire wound) was replaced by a 17.2 ohm 1/2 watt flexible wire-wound

resistor originally salvaged from a Philco farm radio.

Tubes

Correct G type tubes were installed except for the 25AC5G (I have not yet

found a suitable replacement). I purchased one Zenith

and one Raytheon 25Z6G on eBay. I had a good Zenith

6AF5G in stock.

Testing and Alignment

Once the radio was reassembled and the tubes installed, power was brought up

slowly using a variac. AC power consumption was monitored using a watt meter, and a

DVM monitored the B+. The radio came alive immediately and the audio

section worked. There

was some reception on the two short wave bands, but nothing on the broadcast

band. It was later discovered that I had made a wiring error, and the lead

from the broadcast band padder capacitor was swapped with another lead

originating in the RF amplifier sub-chassis. The wire colors are easily

confused due to fading and dirt. Once the wiring was corrected, the radio worked on

all bands. The automatic tuning unit was then installed, and it also

worked.

The B+ voltage was slightly low: 215 volts vs. 225 volts (at 122 volts AC

input vs. the 120 volt specification). I never figured out why this was

the case. The new filter capacitors were tested for correct capacity

before installation, and the two 25Z6G tubes were also tested (as well as

swapped). The 6AF5G and 25AC5G tubes were also substituted - no

change. The two R7 wire wound resistors were close in value to the

specifications. They were also temporarily shorted out with no B+ voltage

change noted. The wiring for the voltage doubler circuit did not match

the schematic, but I left it as it was, since it was obviously original, and

there were other errors discovered in the schematic (so I did not trust it). In any case, the

radio worked well, and the wattage draw was very close to published values in

Riders. Zenith voltages in Riders seldom match the radio in my

experience. The police band (short wave #1) also worked, so the

repairs to the mouse-eaten short wave antenna coil were obviously successful.

The set was then aligned. The radio is difficult to

align because the loop antenna and speaker must be connected while it is

aligned. One trimmer is under the chassis! There were several

problems during alignment. If the short wave band #2 antenna coil trimmer capacitor

M was

peaked for maximum output,

the radio would break into oscillation in the middle of the band. I

diddled with the wiring in the 6A8 tube area with an insulated probe - moving wires

around and changing the lead positions with respect to each other and various

components. Only minor changes in pitch of the noise resulted. So I had

to back off the adjustment of the RF trimmer M for short wave band #2 somewhat to prevent this. This likely affected

the performance on the high short wave band. The police band worked

well after the repair to the antenna coil. There is no trimmer for the

police band.

The push buttons were

adjusted to local stations. The radio performs well, and has very good tone.

Restoration Results

|

Chassis Before Restoration |

Chassis After Restoration |

|

|