Zenith 5-S-29 (5S29) Restoration

|

The Zenith 5-S-29 from 1936 is a 5-tube AC superhet circuit

radio in a fairly ornate tombstone (upright) cabinet. It has the smaller

"airplane" type dial with a "split second" hand which preceded

the larger black

dial sets in 1937. It receives the standard broadcast band and

two short wave bands. It features a tuned pre-selector for the

broadcast band (no RF amplifier, but has a three gang tuning capacitor).

The set had seen minimal servicing in the past. One of the filter

capacitors and a couple of wax/paper capacitors had been replaced. That being the case, I decided to try

to maintain the original top and bottom chassis appearance

and to reverse any previous repairs to the extent possible.

The schematic for the Zenith 5-S-29 can be found on Nostalgia

Air. Any part numbers will refer to numbers on that schematic. |

My

antique radio restoration logs

Overview

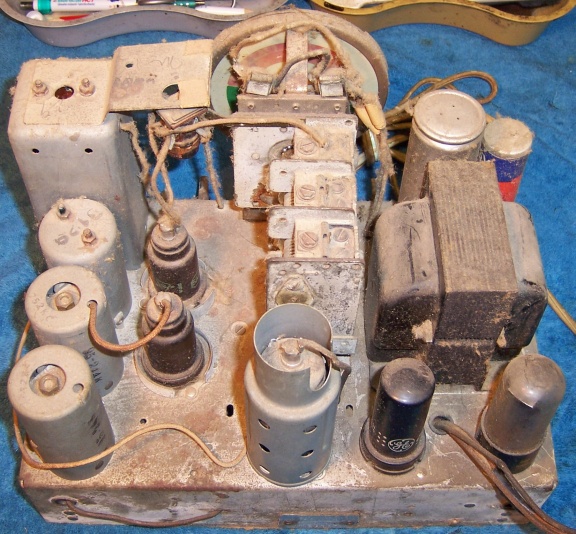

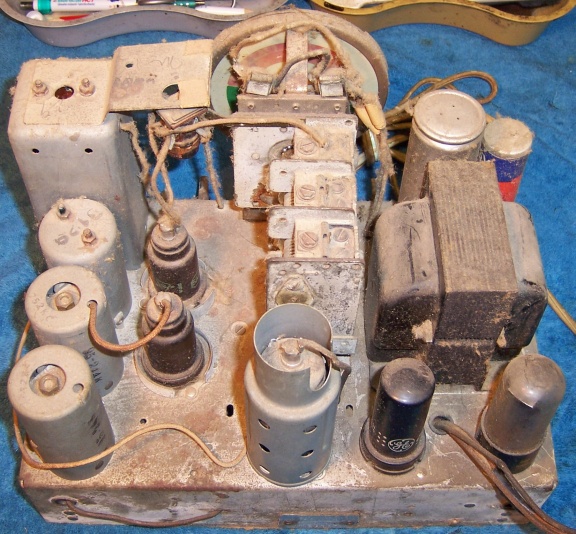

This radio was purchased at the 2012 Antique Wireless

Association conference and flea market in Charlotte, NC. It appeared to be

in original condition with its original knobs, grille cloth, and cabinet

finish. There were signs of prior servicing: one filter capacitor having

been replaced with a newer unit, metal tubes installed and two tube shields

removed, line cord replaced. The cabinet had some scratches, finish loss

and oxidation (foggy finish in places), but looked like

it would clean up and display well and not require refinishing. There were no signs of

an "electrical restoration" such as new wiring. The set was sold as not

working.

Previous Repairs

-

One original filter capacitor C13 had been replaced.

-

A couple of wax/paper capacitors had been replaced (C7,

C15).

-

All resistors appeared to be original.

-

It appeared that all tubes had been replaced. Metal

tubes had been installed for the 6A8, 6K7 and 6F6. The original tube

shields for the 6A8 and 6K7 had been removed. The 6B6 had been

replaced by a 6Q7G with its original shield (an acceptable substitute). In

1936, metal tubes (RCA) would work OK in Zeniths. Later Zenith (as

well as Philco) sets REQUIRED G type

glass tubes

used with shields, since pin 1 (the metal case of the tube) tube was

deliberately not grounded (in many cases, there was no pin 1 present at the

socket, preventing a service tech from grounding the pin and installing a

metal tube.) FYI, Philco went even further by using shield bases with small

holes which prevented using metal or even GT tubes!

-

The power cord

been replaced by a white vinyl cord with old style rectangular plug.

-

The chassis washers had been removed - likely deteriorated -

this meant that the control shafts and dial were not properly centered.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective or

missing and

cannot be restored or replaced, I may elect to sell the radio rather than restore it.

I always assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Any mica capacitors are assumed OK until testing proves otherwise.

-

The volume control and switch were OK.

-

The tone control pot was open.

-

The output transformer primary winding was open.

-

The speaker field and cone, power

transformer, and both IF transformers were good.

-

All of the RF coils were OK.

-

Four resistors had drifted and were now out of tolerance. All

were dogbone types.

-

The four section Candohm metal clad resistor R8 had one open section (the 85 ohm

section), but the other sections were close to correct values.

-

The tuning capacitor mounting grommets had deteriorated (typical).

-

Both pilot lamps were good

-

All chassis washers were missing.

Repairs

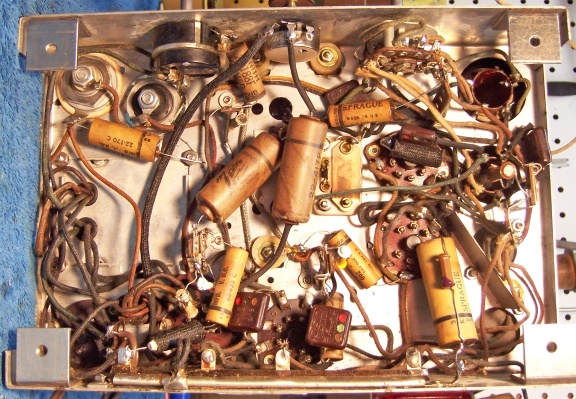

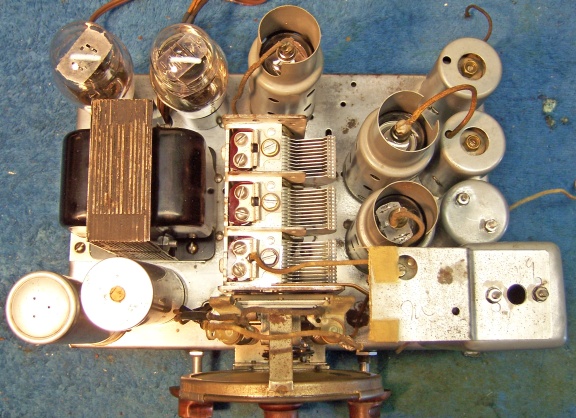

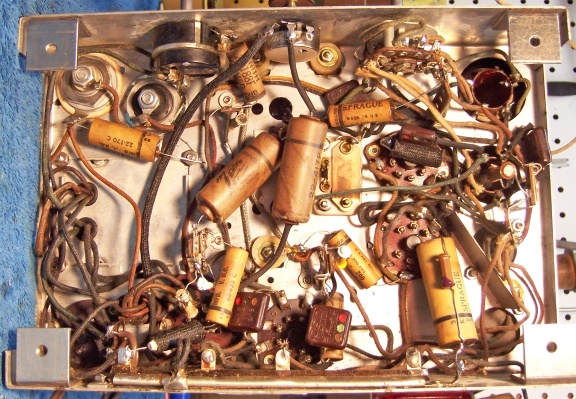

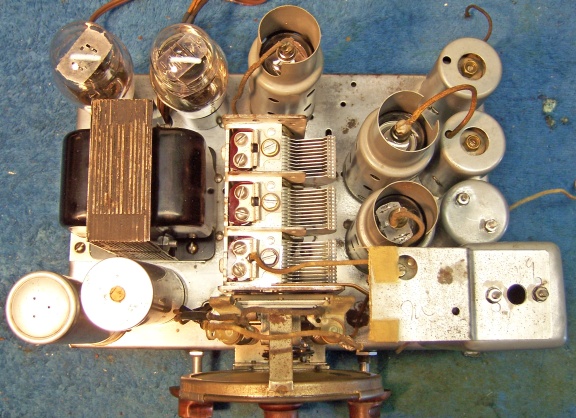

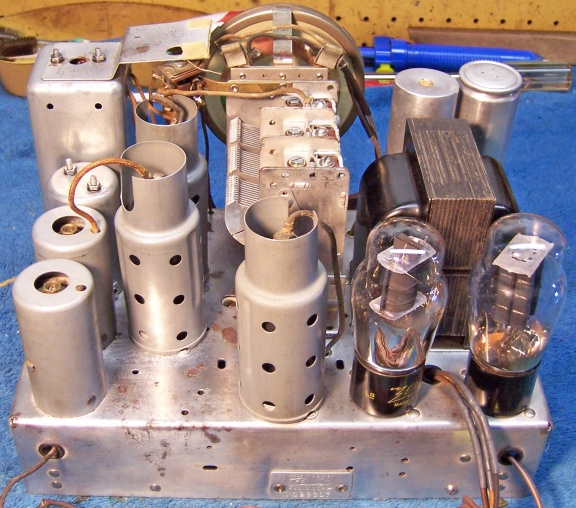

All tubes and shields were removed. Before starting repairs, I took photos of the chassis

top and bottom so that routing of wiring and component placement could be restored.

Lead dress is often critical in radios.

In Zenith schematics, all

resistors and capacitors having the same value have the same part number call

out. So for example, there may be multiple R2's or C4's on the schematic.

Before I start work on the chassis I annotate the schematic so that all parts

have unique identifiers. I usually add an alphabetic suffix, so that the

part numbers are thus R1A, R1B, etc. I then annotate the chassis photo with

these unique part numbers with a red felt-tip pen. I then removed all

non-original capacitors, documenting their locations

and connections. When I replace a component, I

always remove the original part completely from a terminal. Other

components connected at the terminal are protected from heat using old medical

clamps (hemostats). Excess solder is then removed using a solder sucker in order to

expose terminal holes for reattachment of the rebuilt or replaced component.

The top of the chassis was cleaned with GoJo hand cleaner and 00 steel

wool. Since this process may leave metal residue, I then went over the

chassis with a vacuum cleaner followed up by a small magnet and masking

tape. The tuning capacitor speed reduction mechanism was disassembled for

cleaning and lubrication. The tuning capacitor was cleaned in an old Heathkit ultrasonic

cleaner with dilute ammonia. After drying, the ball bearings were lubed with

distributor cam lubricant. The three tuning capacitor mounting grommets

were replaced using Philco GSm-Tuner grommets available from Renovated

Radios, with the small portion sliced off from the bottom side grommets using a single edge razor

blade (the upper grommets were left as is, since the projection sits in a small

indentation in the chassis). These grommets are not exactly perfect for

the application, since their center hole is slightly large, they are very

slightly too thick, and not firm enough. But they will work.

The missing chassis washers were replaced using CW2 washers available from Renovated

Radios. This washer left the knob shafts and dial centered properly.

Output Transformer

The original output transformer had an open primary winding. The

transformer was mounted on the speaker using simple bent-over tabs which fit

into slots in the speaker frame. No bolts were used. So the

replacement would have to have the same frame and tab width. Also, a bracket

was spot welded to the top of the transformer which held the terminal board where the

speaker cable was connected. At this point I was not sure it could be

removed without mangling it. I maintain a stock of (mostly used)

single-ended and push-pull output transformers. I examined my stock of

single-ended transformers and found a potential replacement. It was marked

"42 output transformer", which means it was originally used with a

type 42 tube (standard base version of the 6F6G used in this radio). The

ratio of the transformer was measured as 39.7:1. The voice coil of the

speaker measured 4.7 ohms DC, or about 5 ohms impedance. The 6F6 output

tube wants to see a load impedance of 7000 ohms. So the needed transformer

ratio is thus 37.4 (square root of 7000 divided by 5). So the turns ratio, DC

current and power ratings of the replacement transformer were acceptable. The core of the potential

replacement was VERY close to the size of the original. So I was able to

remove the original transformer core from its frame and substitute the core and

coil of the replacement. That way the replacement could be reinstalled on

the speaker and original terminal board bracket used. Other than

minor differences in lead routing, the replacement is not obvious!

Resistors and Capacitors

The four section Candohm resistor (R8) had one open section initially (the 85

ohm section), but most other sections were close to correct. I have found

that these metal clad resistors often respond favorably to clamping pressure

near their terminals when a section is unstable or has high resistance. I use

a small C-clamp and firm pressure on the metal housing on both sides near each terminal.

Thin wood or cardboard protects the chassis side of the clamp. Each terminal is simply a band around the resistance element, which is wound on

an insulator. Over time, the band expands or the insulator shrinks,

resulting in an unstable, high resistance, or sometimes an open section. In

this case, after squeezing, all sections were almost exactly correct and were

stable (resistance did not change when the terminal lug was moved)!

Compressing the metal case applies additional pressure from the band onto the

resistance element. There is some risk to this procedure, since the fish

paper insulation may be damaged in some cases, resulting in a short. For

this reason, many collectors never re-use a Candohm resistor in a restoration,

even when good! Instead, they remove the resistor and install terminal

strips and individual wire wound resistors. This of course greatly alters

the under-chassis appearance of the radio. I would also replace a Candohm

resistor, and especially if part of it was bad, if being PAID for a

restoration. But this radio will be a keeper (which will rarely if ever be

played).

The tone control measured open. It was removed from the radio for

examination. It turned out to be the non-repairable type, consisting of a

thin layer of carbon deposited on a cardboard form. A thin flexible metal plate contacted

the element. The rotating element applied pressure to the plate through an

insulator, so that the rotating arm did not directly contact the resistance

element. The element measured open, and cleaning simply removed the

carbon coating! So this control had to be replaced. It was replaced

by the correct IRC part (D13-123, 50K, audio taper) called for in the IRC manual

for this Zenith chassis. The D-type shaft that came with the control fit the

original knob. The shaft was cut to the correct length, and the original

star washer and nut was reinstalled.

All the original wax/paper capacitors were rebuilt in their original cases

using modern 630 volt film capacitors in order to maintain the original

under-chassis appearance. I reseal the cardboard tubes using rosin

salvaged from servicing RCA Radiola Superheterodyne catacombs (it melts at a low temperature and will not damage

the replacement capacitors). The set uses a mixture of capacitor

types including Zenith, Sprague and Cornel Dubilier. However, even though some capacitors are not branded Zenith, they all

had Zenith part numbers. Here

is how I restuff the Zenith and Sprague tubular capacitors. Here

is how I restuff Dubilier CUB capacitors. Two original wax/paper caps (C7 and C15) had been replaced in prior

servicing. I was able to find original Zenith capacitors in my parts stock

which had the correct values and part numbers that matched the

schematic. I collect Zenith and other branded paper capacitors for this

exact situation. These replacement capacitors were also rebuilt using new 630 volt film capacitors.

One of the original filter capacitors C13 and

was missing and had been

replaced in prior servicing. However, I had a screw base can type

capacitor in my parts stock which had the correct diameter and approximate

length. It also had a threaded stud for the positive terminal, which would

allow use of the existing original wiring (both original lugs were still in

place - one being simply soldered to the lugs of the replacement capacitor and

not cut off). One capacitor must be insulated

from the chassis, and the other is grounded. I moved the original

capacitor (which was originally grounded to the chassis) to the hole for the insulated capacitor (closest to the edge of the

chassis) since I had the appropriate insulating washers in stock that would fit

that capacitor. The replacement capacitor can was installed in the other hole.

I had not insulating washers that would fit that capacitor. The insulating

washers are not simple flat washers: they have a projection that fits in the

chassis hole to prevent the capacitor from contacting the chassis should it

move. These are generally obtained from parts chassis.

The original C13 and replacement (8 mfd, 440 volts) were both restuffed using 10mfd 450 volt capacitors. The cans were scored deeply

about 1" up from their base on my Unimat lathe, and then the cut was

completed using a

Exacto hobby razor saw. In the case of the original capacitor, the positive electrode

(foil) was removed, retaining the

stud. The stud was cut off short and a hole drilled for a screw, nut, and

solder lug. A plus lead of a 10mfd 450 electrolytic was connected to the solder

lug. The negative lead of the replacement capacitor, extended with bare

bus wire and with insulating

sleeving, was routed through a small hole drilled in the base near the mounting

threads. After the

capacitor was mounted, the negative lead was soldered to the a replacement

negative terminal (the original had been cut off). The original positive terminal was used.

The replacement capacitor was a "dry" type and did not have an

internal center

stud. Once its contents were removed and it was cleaned up, a small hole

was drilled next to the positive terminal threaded stud. The positive lead

of the replacement 10mfd capacitor was extended with 22 gauge bus wire and

routed through the hole. The existing original inside nut on the positive

lug was removed, the bus wire wrapped around the stud, and the nut

replaced. The negative lead of the replacement 10mfd capacitor was routed

through a small hole drilled in the base near the edge. This lead was

clamped between the capacitor body and the chassis when the capacitor was

mounted. Just in case, the lead was also clamped under a nearby power

transformer mounting nut.

All small resistors in the set were dogbone types, and most were 1/3 or 1/4 watt

size. Four were not in tolerance and would have to be replaced. In

order to maintain the under chassis appearance, I decided to use the same type

resistor to replace them. But of course, any replacement

dogbone resistors would also likely have drifted! I collect all the used and NOS dogbone

resistors I can find, and retain any out of tolerance dogbone resistors that I remove

from radios. I searched my 1/4 watt dogbone resistor stocks for resistors

which had the correct lead length and value within 15% or so. I then repaint these

resistors with the appropriate body-end-dot color code of the ORIGINAL resistor using

enamel hobby paint.

Wiring

The speaker cable had insulation breaks and had bare wire showing near the

chassis. But most of the cable was usable. The cable was repaired by

cutting each wire at the bare portion and installing two layers of shrink tubing

on each wire, one wire at a time. The same process was used to repair the pilot

lamp leads. For some reason, the original pilot lamp leads had been cut, spliced (not

soldered!) and insulated with tape. Since the dial drive belt had been

replaced, perhaps the front of the dial drive mechanism was removed in order to

install a replacement (a few wraps of twine!) But the pilot lamp sockets could

have simply been pulled off their mounting brackets in order to do

this!

During testing, it was discovered that the antenna lead was shorting out to

the antenna coil shield, where it passes through an eyeleted hole. It was

repaired by pulling the wire back through the hole, cutting off the bare and

damaged part, replacing the knot (strain relief) and reconnecting the lead to

the antenna coil.

The original power cord had already been replaced, so I had no idea what the

original looked like. But postings on Antique

Radio Forums indicated that 1936 Zeniths had standard flat brown rubber

(vinyl) cords with integral molded plugs (1935 and earlier had cloth covered

cords). So I installed a standard replacement brown vinyl cord with molded

plug.

All other wiring in the set was cloth covered and in excellent condition.

Other Repairs

The band switch was given a good spraying with GC Big Bath cleaner, which

leaves behind no residue. The dial drive speed

reducer was disassembled and its parts cleaned in my Heathkit ultrasonic cleaner

using dilute ammonia, followed by cleaning with soap, water, and toothbrushes.

Gear hubs were cleaned using a pipe cleaner. The mechanism was then

reassembled and oiled using Turbine oil. The dial drive belt was replaced

by a 2" diameter thin (about 1/16" thick) O-ring. The mechanism then worked

perfectly.

Testing and Alignment

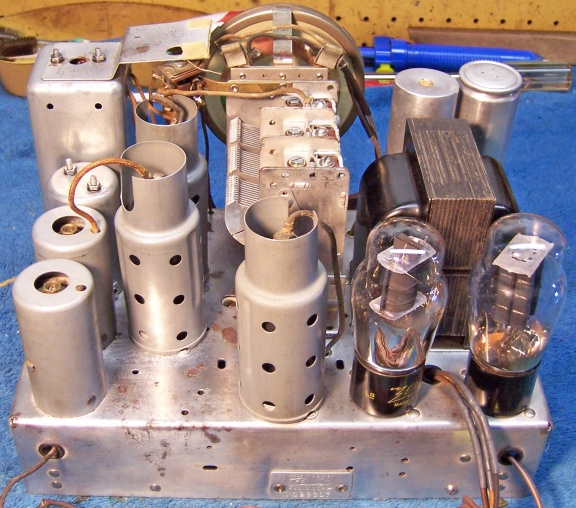

Once the radio was reassembled and the tubes installed, power was brought up

slowly using a variac. AC power consumption was monitored using a watt meter, and a

DVM monitored the B+. The radio came alive immediately and worked. The set was then aligned. The

only problem found was that the pre-selector trimmer did not peak up properly

(it was left wide open). The

radio worked well and picked up lots of stations on all bands using only a 20' piece of wire

in my basement. The tone was very good, so the output transformer

replacement was successful.

Restoration Results - After Restoration