RCA Model 110 Cathedral Restoration

My

antique radio restoration logs

|

|

The RCA Model 110 is a 5-tube AC non-AVC superhet circuit

radio. It receives the standard broadcast band and the old police

call band. The circuit is somewhat unusual, in that it has an RF

amplifier stage but no IF amplifier stage. The schematic can be found

on-line at Nostalgia

Air. Any part numbers will refer to numbers on that schematic. |

Condition As Found

The radio was purchased on eBay. It was described as working with its

original parts (I was skeptical)! I downloaded the photos in eBay and enlarged

them as much as possible. It did indeed appear that most if not all original

parts were still present, although I did see some tacked-in filter

capacitors. When the radio arrived, I confirmed that all the original

parts were present. No parts had been replaced, but several filter

capacitors had been disconnected and newer tubular capacitors installed.

It appeared that the radio had been serviced multiple times, since there were

several generations of replacement filter capacitors present. Once it was

determined that there were no B+ shorts, I slowly powered up the radio using a

fused variac and watt meter, with a DVM monitoring B+. One resistor had

broken loose from the volume control, and the antenna lead had broken off from

the antenna coil. Once these were repaired, the radio did indeed work as

advertised! This is truly amazing on original parts (one of three filter

capacitors was original). The cabinet was

in great original condition, as were the knobs and grille cloth. The power

cord had been replaced by a newer cloth covered type. All of the grid cap

leads had been replaced with new wire (correct cloth covered type). From

prior experience with this vintage GE/RCA, most of the original grid cap leads

were rubber covered and the insulation would be flaking off, resulting in shorts to the

tube shields.

I decided to try to reverse any previous servicing to the extent possible

and to restore as much of the original top and bottom

chassis appearance as possible. My objective was that any repairs or

restoration would not be obvious, and no new parts visible. The objective

was NOT to return the radio to factory new condition! This same chassis is used in several RCA and GE radios.

I had previously restored a very similar chassis, the RCA

R-28P. But that radio had seen extensive servicing and many original

parts had been removed. This one was largely original.

Survey

My usual restoration procedure is to first make a complete

survey of the condition of all components. The survey results guide my

restoration strategy. If major and unique components are defective and

cannot be restored, I may elect to sell the radio rather than restore it.

I assume that all paper and electrolytic capacitors are leaky and thus should be

replaced (I always "restuff" the original containers if possible).

Since this radio actually worked, it was assumed that all major parts were OK. I

did check the power transformer for balanced high voltage across the center tap

and wattage draw with no load. It was OK, even though there were signs of

tar or wax leakage on the chassis. This was likely due to overheating and

high current draw due to leaky capacitors in the past.

-

One original tube shield had been replaced by one that did

not properly fit. Luckily, I actually found a correct original shield

in my junk box!

-

The volume control (a 4.5K wire-wound control with switch) was

open at some point. A common failure mode of these controls, which use

several sections of different size resistance wire, is a break between

sections due to failed welds or other methods of joining the nichrome wires.

-

The power switch (on the volume control) measured high

resistance - likely due to dirt and corrosion.

-

The tubes were stated as tested and replaced as

needed. All tubes tested strong, except for the 2A7 which tested weak

(but did work).

-

Six resistors were out of tolerance. All were old style

"dogbone" resistors in various sizes.

Repairs

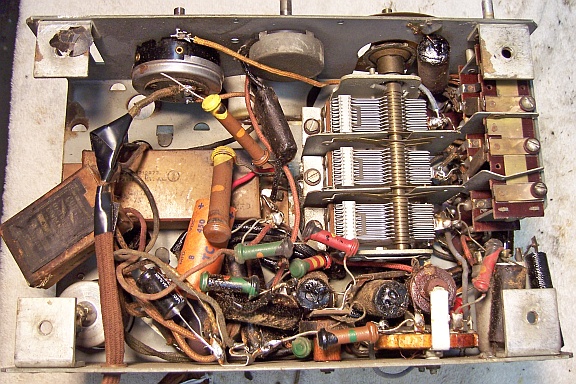

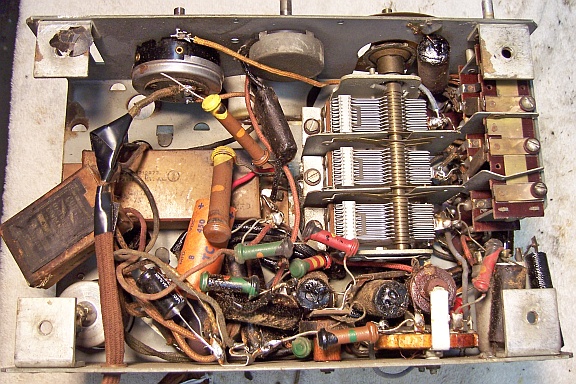

The chassis is very compact and there is really no way to service many of the

components without removing others for access. Here is what the chassis

looked like before the start of restoration. The loose 14K resistor is

supposed to be connected to the volume control rheostat:

First, all non-original parts were removed after taking careful notes of where they connected.

Several parts that originally had been connected to one lug of the two-section

filter capacitor were moved back in the vicinity of the lug (as found, they were

hanging in mid air and connected to tacked in filter capacitors). I

then took more photos of the chassis, since this would likely represent the

original condition prior to servicing. In order to gain access to the capacitors and resistors that needed

replacement, I removed the tuning capacitor, the volume and tone controls, the

speaker (chassis top), the filter capacitors, the detector plate

choke L9, and the

antenna and RF coils (on top of the chassis, L1-L4). One must be VERY

careful with the speaker leads, which are sleeved and quite stiff. They

are easily damaged, and a tight fit through a hole in the chassis which has no

grommet.

Capacitors

All paper capacitors were rebuilt

using modern 630 volt axial film capacitors in order to maintain the original

under-chassis appearance. There were two types of paper capacitors used in

this radio: the first type was a cardboard tube containing the paper-foil roll

with its ends sealed with tar (not wax). These are very easy to

restuff. First the component leads are pulled out of each end, which also takes much

of the tar with them. Then the foil roll is pushed out one end using a

screwdriver. The cardboard tube is then cleaned of any remaining tar. I also clean the outside of the tube by heating with a heat gun and

wiping away the wax, tar, and dirt. A new axial film capacitor is then

inserted. Before restuffing, the

component's original lead length and any insulating sleeving use is noted. In

some cases longer leads must be first attached to the replacement capacitor

before restuffing (I use #20 or #22 solid tinned bus wire to extend the leads).Here is the method I use

to rebuild cardboard tube type capacitors.

The other type of paper capacitor used in this radio has no cardboard

tube. These look like a block of tar wrapped in a thin fish paper wrapper, and

are generally oblong in shape rather than round. I came up with a way to restuff (more correctly

to reproduce) these RCA capacitors. See Restuffing

Early 1930's RCA Paper Capacitors. The tone control and quality

capacitor C20 and C30 was this type, and contained two capacitors (.035 and

.005mfd).

It was reconstructed using a .0047mfd (the quality capacitor) and a .015mfd

and .022mfd capacitor in parallel (the tone control capacitor). Two

capacitors in parallel were used because a .033mfd was too thick, and because

of the shape of the original capacitor. The original outer fish paper wrapper

(complete with part number) was reattached using hot glue. Capacitor C13 (2400pf) appeared to

be a paper capacitor rather than mica. It was in a very difficult position

to remove it (under the band switch), and would be difficult to reproduce. I disconnected one end

and measured leakage and capacitance. Leakage measured more than 40

megohms DC (infinity) on my DVM, but the capacitance measured 4200pf using my DVM's capacitor measurement

function (a higher reading usually indicates a leaky capacitor). Since it was shunted by a 20K

resistor and was only exposed to low voltages, I left it in place.

The wet can type electrolytic capacitor C21 was rebuilt in its

original can. The original was 10mfd, voltage unknown. The can was deeply scored about 1" up from the base

using my small Unimat lathe and the cut completed using a hobby razor saw. In

this case, it was completely dry - with no electrolyte inside (otherwise, the process

can get messy!) This

cut would be hidden by the capacitor's mounting clamp. The original

contents were removed (positive electrode foil and insulation sleeve) and the case

was cleaned. The positive center stud was cut short and a hole drilled in

the end in order to attach a ground lug using 4-40 hardware. The positive

terminal of the 10mfd/450 volt replacement capacitor was soldered to the ground

lug. The negative lead of the replacement capacitor was extended, insulated with spaghetti tubing, and

routed through a hole drilled into the side of the capacitor. The negative

lead would eventually be clamped between the capacitor can and the mounting

clamp and thus hidden. The two halves of the can were joined using 1" PVC plumbing couplings and

epoxy cement. I also apply a few layers of masking tape to the PVC coupling to

take up excess clearance with the can. The original mounting clamp

was very rusty. It was removed from the chassis by drilling out two

rivets. It was then cleaned up using wire brushes on my bench grinder and

using a Dremel tool with a small wire brush. It was then reattached to the

chassis using 6-32x1/4" hardware. The negative lead of the capacitor

(hidden by the top of the clamp) was routed through the capacitor mounting hole

and clamped under one of the mounting nuts to ensure a good ground connection.

The cardboard cased block capacitor C22/C23 (2 x 4mfd at 300 and 150 volts) was opened up and

restuffed using two 4.7mfd/450 volt electrolytic capacitors. First the

backs of the three hollow rivets were ground off using a Dremel Mototool with a

grinding stone. The rivets could then be removed from the top with minimum

damage to the cardboard case, and could be reattached later. The stiff bottom cardboard

base was then removed using a

heat gun to melt the glue and wax. The capacitor case was then carefully

opened, again using the heat gun. The capacitor inside was then removed

after severing the foil connections to the back of the external terminal rivets. Excess foil

was then removed from around the terminals from the inside using a sharp Exact

knife and #11 blade. Small holes were

then drilled through the center of the rivets holding the terminals and through

the cardboard on the back side. Two 4.7mfd at 450 volt capacitors were

then mounted inside, and their positive leads were routed through the drilled

holes. The leads were then wrapped around the terminals on the front side

and soldered. The negative leads of both capacitors were joined to a piece

of bare bus wire, which was insulated using small spaghetti tubing, routed

through the drilled hole in the common external lug, wrapped around the base of

the lug and soldered. The capacitor was then reassembled and held together

using hot glue. The bottom cardboard base was reattached using hot

glue. The three rivets were then reinstalled. Two are held in place

by the capacitor's mounting screws. The one that did not have a mounting screw to hold

it in place was secured using a small dab of epoxy.

Here are the

restuffed filter capacitors:

All the mica capacitors were left alone. Any of these that could be

tested by lifting one lead (in the process of replacing another part) were

tested. All that I tested were good.

Resistors

All original resistors significantly more than 20% out of tolerance were replaced. I

used dogbone type resistors as were used originally. I purchase all the NOS

and used dogbone resistors I can find on eBay or at antique radio swap

meets. I picked out NOS and used

dogbone resistors from my collection that were either in tolerance or had drifted to the correct needed resistance and then repainted them to

match the original resistor's color codes using hobby enamel paint. The replacements may continue to drift, as would most new carbon

composition type resistors. But to me, maintaining the original look is

more important than long term reliability of the radio. And besides, most

modern collectors would simply rip out all the vintage parts and replace them

with new parts without even testing them!

|

Here are the replacement dog-bone

resistors, ready for installation in the radio. Three are NOS or used parts that are still in tolerance (the 60K, 1 Meg, and 20K). The other two

have been repainted using hobby paint. The NOS 14K 1 watt resistor was

originally a NOS 10K, but now measures 14.03K. The 200K 1/2 watt was originally

100K but now measures 186K.

|

Volume Control

The volume control was intermittent in operation (the resistance jumped around) and measured open circuit at some

point of rotation. I originally suspected a break in the resistance wire -

a common failure mode. The control was removed from the radio and was disassembled. It was found that there was no break in the resistance

wire - apparently the control only needed cleaning! The C-clip retaining

the shaft was removed and the shaft and wiper removed. All parts were then

cleaned using lacquer thinner. A Q-Tip and lacquer thinner was used to clean the resistance

wire contact area. The wiper showed some wear and corrosion. The

contact area was smoothed using 600 grit emery paper and then cleaned using

lacquer thinner. Upon reassembly, the control operated smoothly throughout its

range. The resistance measured 5.6K ohms rather than the specified 4.5K

ohms. The minimum resistance was 115 ohms (not specified in the Riders

documentation). The control was marked "RCA-VICTOR CO." so it

must have been original.

Other Repairs

- The tuning capacitor rubber grommets were replaced using standard AES

P-G038 rubber grommets which worked perfectly, although they were likely stiffer than the

original parts.

- The chassis was cleaned using GoJo and steel wool, tooth brushes, small

bottle brushes, and pipe cleaners. Since use of steel wool may leave

behind conductive fibers, I then went over the chassis with small magnets, a

vacuum cleaner, and masking tape.

- The band switch was cleaned using lacquer thinner, Big Bath spray cleaner,

and finally Caig DeOxit D5. Contact resistance was tested prior to

reassembly of the radio.

- The line cord was replaced with a new reproduction cloth covered cord and

old style plug. The cloth covered cord that came with the radio was

much too thick.

- The original 80 shouldered or ST style rectifier was replaced. In the radio,

the rectifier socket is recessed. I assume this is to allow room for a

globe type 280 rectifier, which I installed. The globe style tube looks more correct

than a ST type tube. 1933 was about the time that globe type tubes

were being phased out. It is not known which type was originally

installed.

- The original rubber covered grid cap leads had already been replaced, and the

remaining original wiring was OK. Insulating sleeving was installed on

each grid cap lead to prevent shorting to the tube shield.

- The original ground lead had been cut short, and the antenna lead had been

replaced. Both were replaced using cloth covered wire of the correct

color, and were knotted around the antenna coil bracket as shown in the

schematic.

Testing and Alignment

Once the radio was reassembled and tubes installed, power was brought up

slowly using a variac. AC power was monitored using a watt meter, and a

DVM monitored the B+. The radio came alive immediately and worked. Warm-up

is slow, likely due to a weak 2A7 first detector tube.

The set was aligned - no surprises. It picked up lots of stations

using my basement 50' antenna. It even picked up some stations on the "police" band

in the middle of the day (including the local low-power traffic station at 1610.

Tone was OK, but there was some distortion which is characteristic of the type

of second detector used.

Restoration Results

I was able to successfully reverse previous repairs and to restore the radio

to its unserviced appearance. No replacement parts are visible except for the power cord, grid cap leads, and the antenna and ground

leads. It is likely that some of the components were not in exactly the

same position as installed at the factory, since the radio had already been

serviced when I received it. And there is a slight difference in

appearance between the tar originally used to seal the paper capacitors and the

rosin that I used.

|

Before Restoration (Non-Original Parts Removed |

After Restoration |

|

|